Construction engineering wall surface cavity detector

A construction engineering and testing machine technology, applied in measuring devices, material analysis using sonic/ultrasonic/infrasonic waves, solids analysis using sonic/ultrasonic/infrasonic waves, etc. Strengthen the connection relationship, not easy to slide relatively, and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

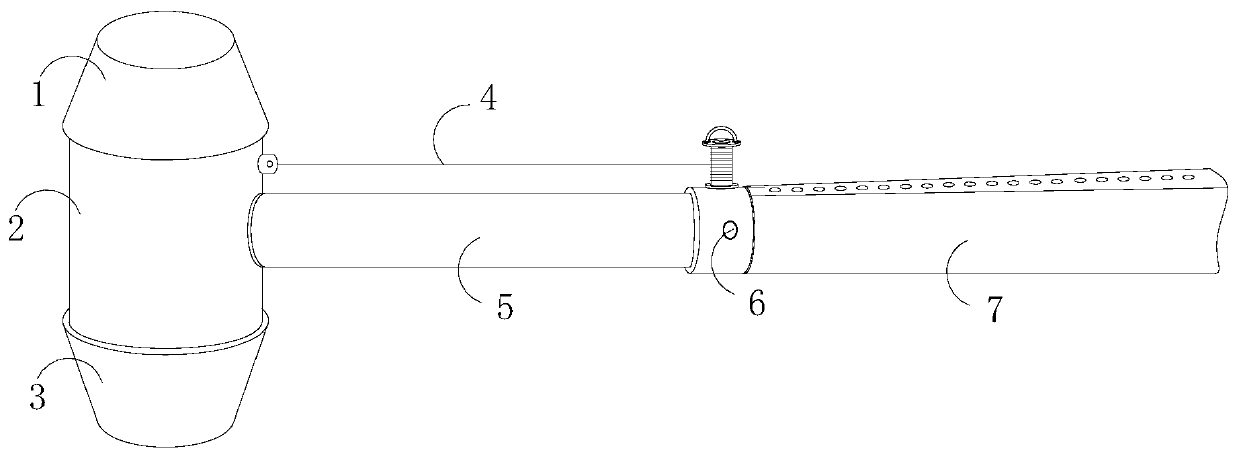

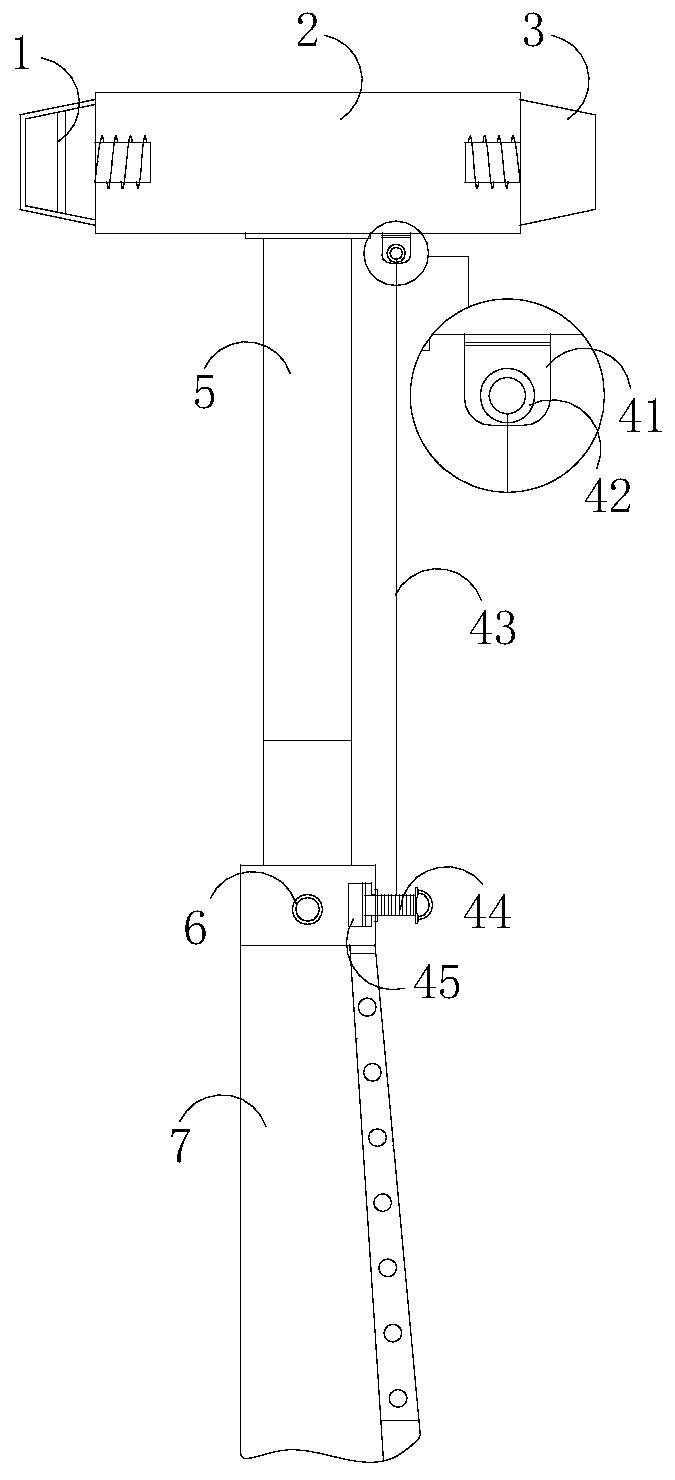

[0030] see Figure 1-Figure 7 , the present invention provides a kind of construction engineering metope hollow detection machine, and its structure comprises hammer head 1, connecting head 2, magnetic head 3, elastic elastic pressure structure 4, telescopic rod 5, pressing structure 6, grip rod 7, described telescopic rod One end of 5 is fixed to the handle bar 7, and the other end of the telescopic bar 5 is welded vertically to the middle of the connecting head 2. The two horizontal ends of the connecting head 2 are respectively equipped with a hammer head 1 and a magnetic head 3. The telescopic bar 5 and the The joints of the grip bar 7 are respectively equipped with an elastic elastic pressing structure 4 and a pressing structure 6 , the pressing structure 6 cooperates with the telescopic rod 5 , and the other end of the elastic elastic pressing structure 4 is connected with the connector 2 .

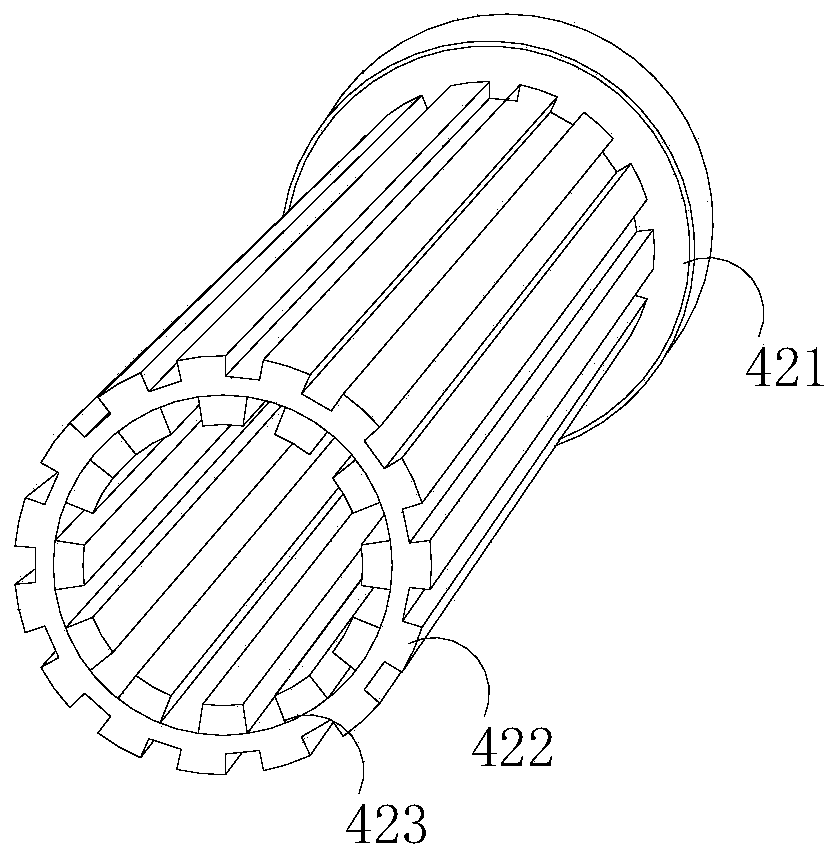

[0031] The elastic elastic pressing structure 4 is provided with a mounting hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com