Die-cut plate loading device of die cutting machine and application method thereof

A die-cutting board and die-cutting machine technology, applied in transportation and packaging, loading/unloading, metal processing, etc., can solve the problems of troublesome replacement process, low work efficiency, occupying space, etc., to facilitate maintenance and installation, and improve space. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

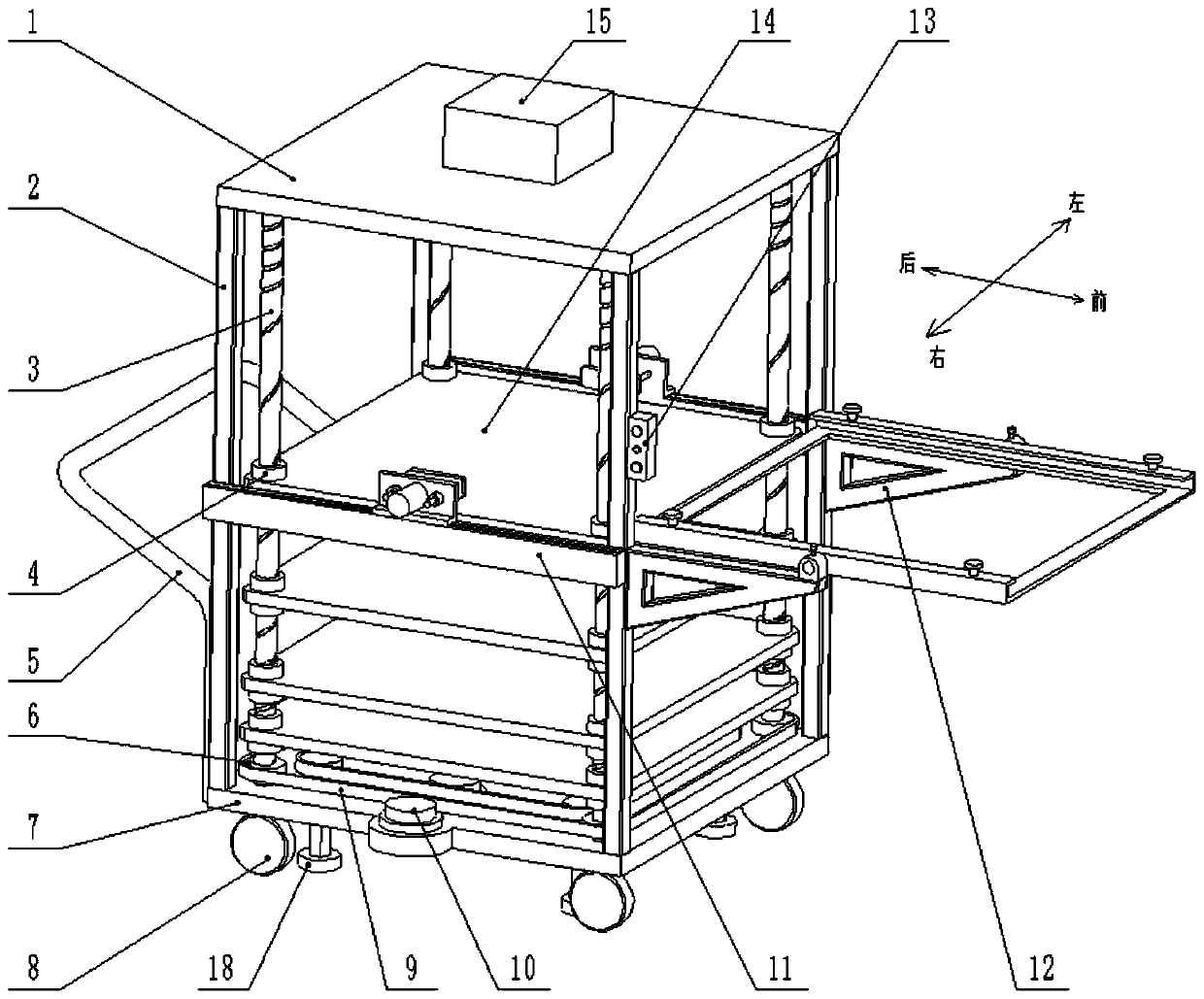

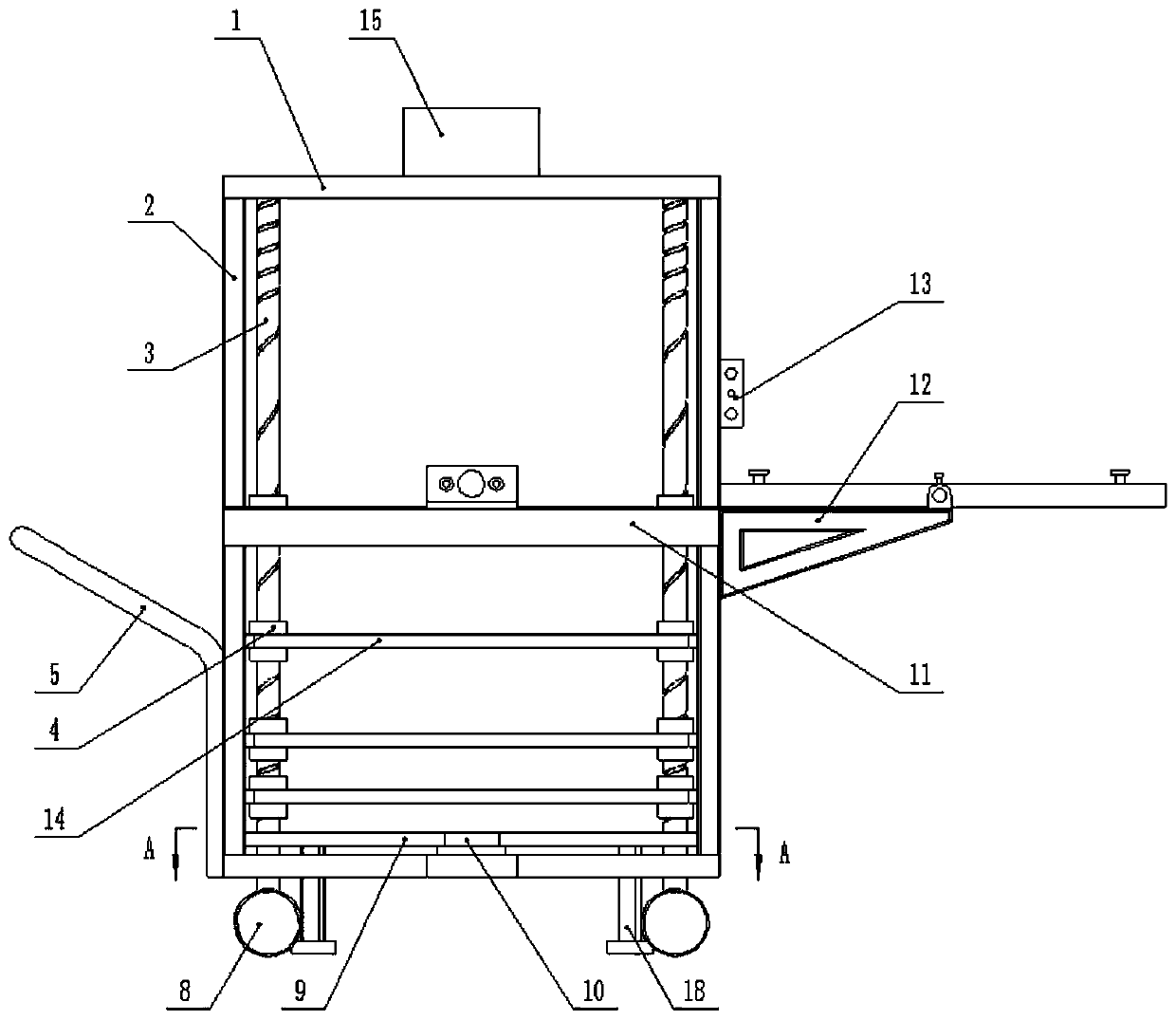

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

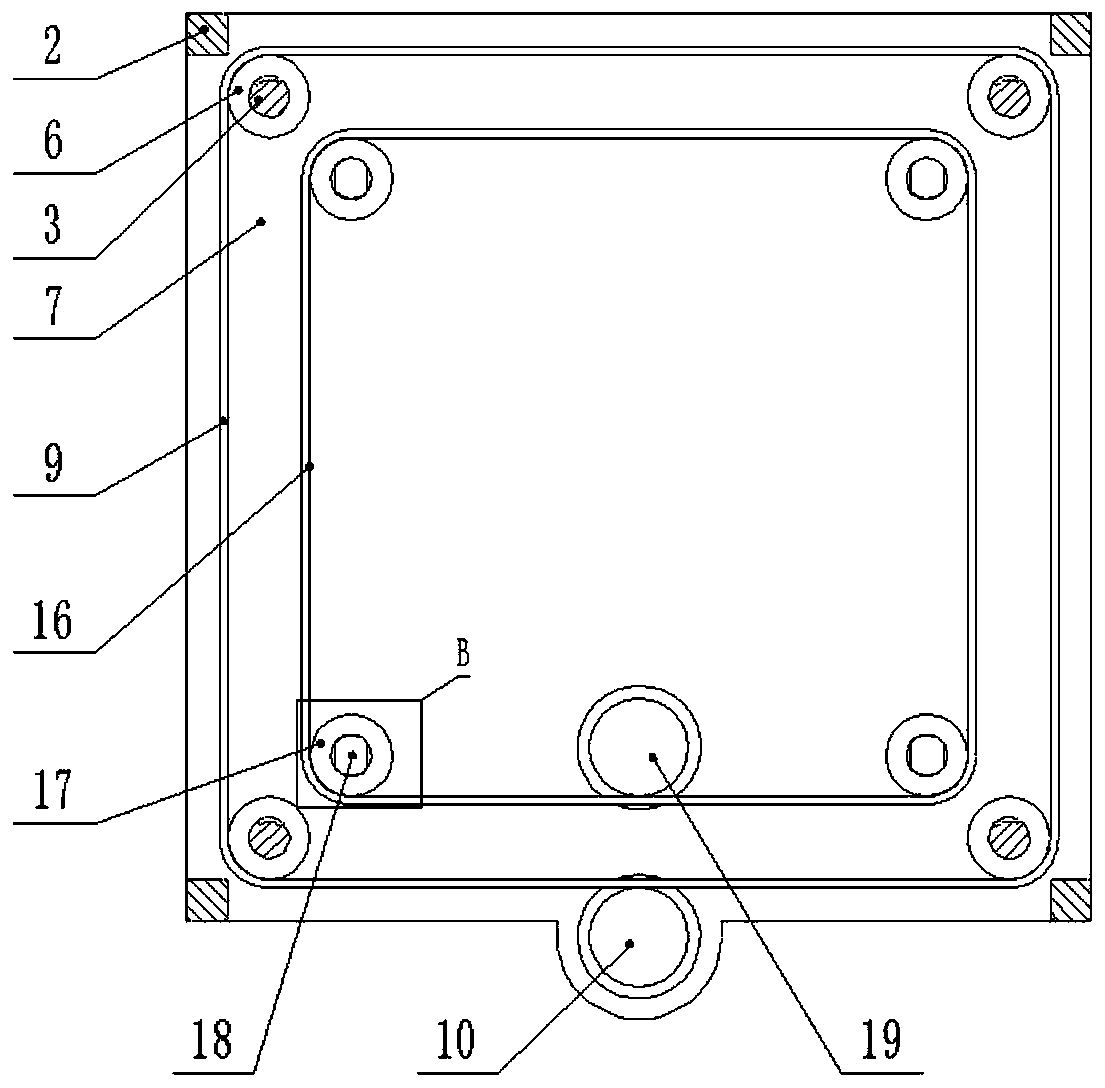

[0046] A die-cutting plate loading device for a die-cutting machine includes a storage rack, the storage rack includes a top plate 1, a bottom plate 7, and a column 2, and the top plate 1 and the bottom plate 7 are fixedly connected by four-corner columns 2.

[0047]The four corners of the bottom plate 7 are provided with rectangular holes 701 , and the lifting base 18 is inserted into the rectangular holes 701 . Lifting seat 18 includes threaded column 1801 and support disc 1803, and the outer periphery of threaded column 1801 is provided with thread, and threaded column 1801 is provided with two positioning surfaces 1802 arranged in parallel, and the distance between two positioning surfaces 1802 is slightly smaller than the rectangular hole The width of 701, lifting seat 18 can not rotate in rectangular hole 701, and lifting seat 18 can only move up and do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com