Magnetic gear

A technology of magnetic gears and gear bodies, applied in the field of magnetic gears, can solve problems such as meshing dislocation, damaged gears, and inability to adapt to gear transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

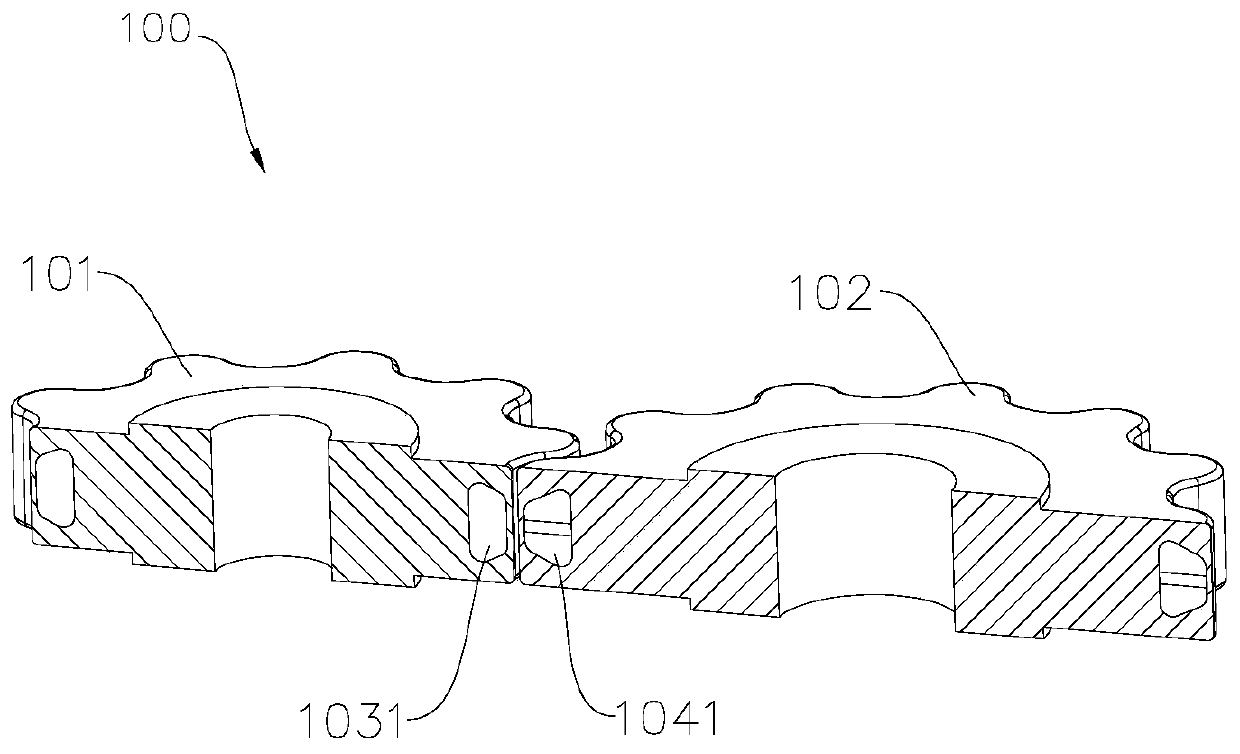

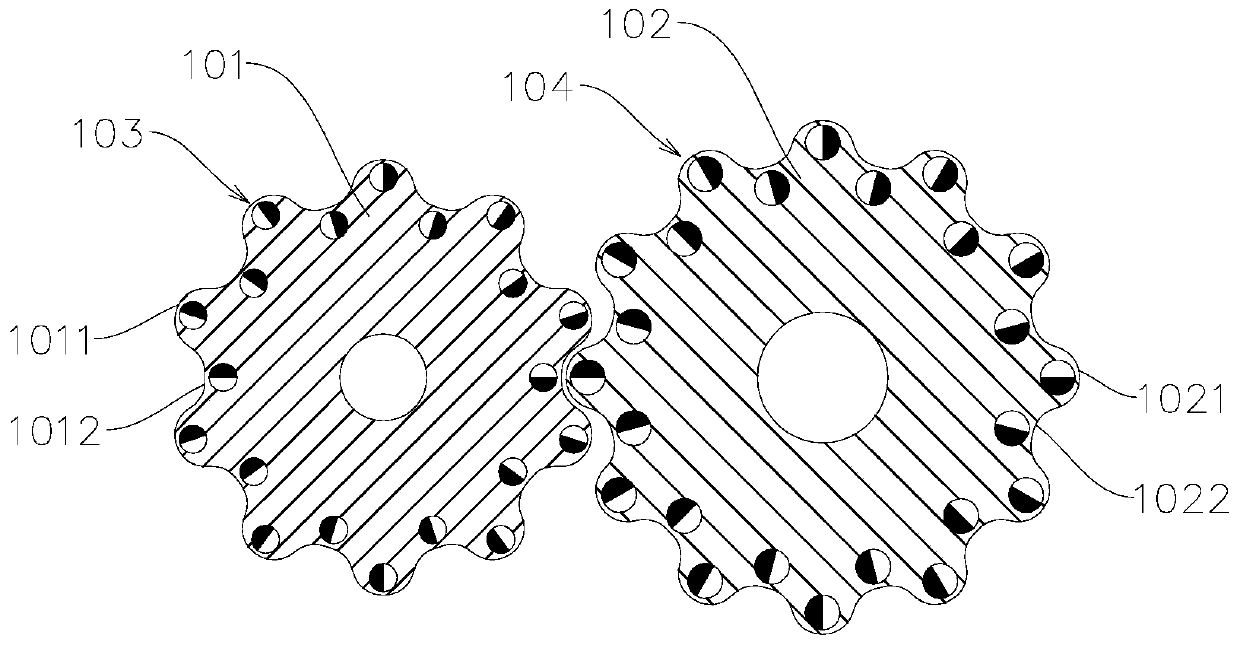

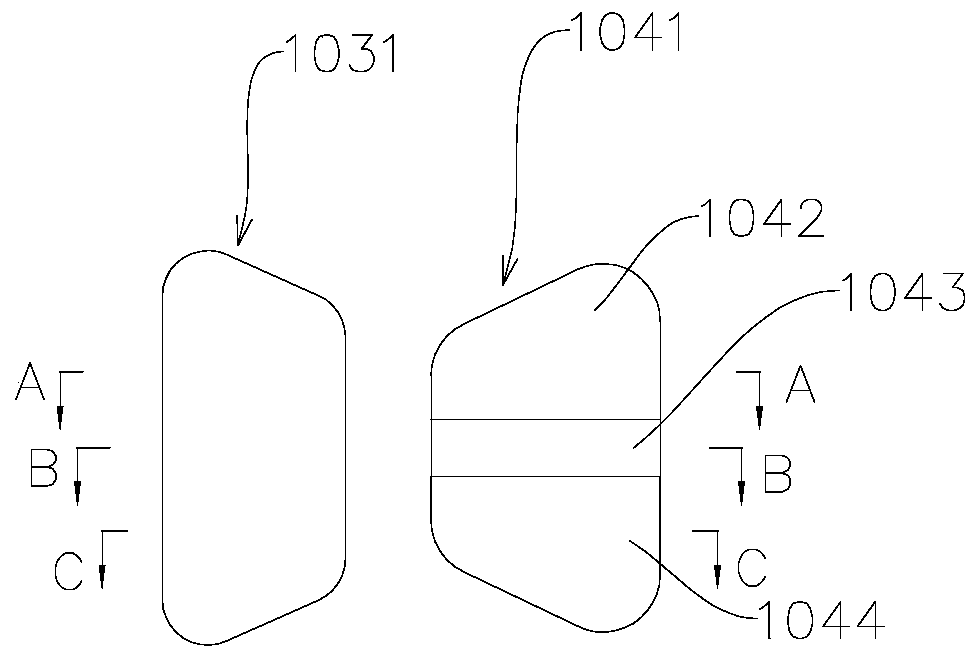

[0031] according to figure 1 , figure 2 , image 3 In a comprehensive analysis, the magnetic gear 100 includes a gear body and a magnetic source. The gear body includes a first gear body 101 and a second gear body 102 , the diameter of the first gear body 101 is smaller than the diameter of the second gear body 102 . Preferably, the diameter of the first gear body 101 is about half of the diameter of the second gear body 102 . First magnetic source arrays 103 are uniformly distributed along the circumferential direction of the first gear body 101 , and second magnetic gear arrays 104 are uniformly distributed along the circumferential direction of the second gear body 102 . The first magnetic source 1031 of the first magnetic source array 103 is distributed near the outer side of the first gear body 101 , and the second magnetic source 1041 of the second magnetic source array 104 is distributed near the outer side of the second gear body 102 . The magnetization direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com