Wind energy rotary piezoelectric-electromagnetic composite power generation device

A power generation device, wind rotation technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem of difficult power supply, low power generation efficiency, and energy utilization in harsh environments low problems, to avoid environmental pollution and increase the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

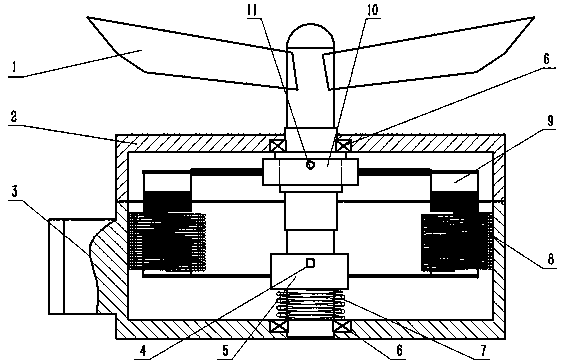

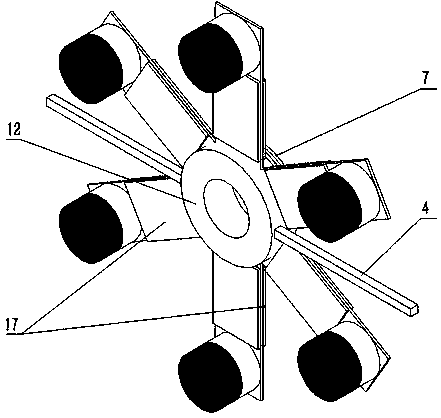

[0013] Specific implementation method: the wind-driven rotary piezoelectric-electromagnetic composite power generation device includes fan blades (1), dust cover (2), base (3), guide rod (4), stator base (5 ), bearing (6), spring (7), coil (8), magnet (9), rotor base (10), positioning hole (11), elastic support beam (13), stator guide slot (15), ceramic Piezoelectric sheet (17), transmission shaft (18), and limit plate (19); the magnet (9) is pasted on the elastic support beam (13) to form elastic vibrators, a total of 6 elastic vibrators, and the circumferential array of elastic vibrators is in On the rotor base (10), the rotor (16) of the power generation device is formed; the magnet (9) and the ceramic piezoelectric sheet (17) are pasted on one end of the elastic support beam (13) to form a piezoelectric vibrator. 6 piezoelectric vibrators are arranged in a circular array on the stator base (5), and the bottom surface of the stator base (5) is fixed with springs (7), consti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com