Overhaul period optimization method for intelligent substation protection system

A technology for intelligent substations and protection systems, applied in system integration technology, information technology support systems, instruments, etc., can solve problems such as waste of maintenance resources

- Summary

- Abstract

- Description

- Claims

- Application Information

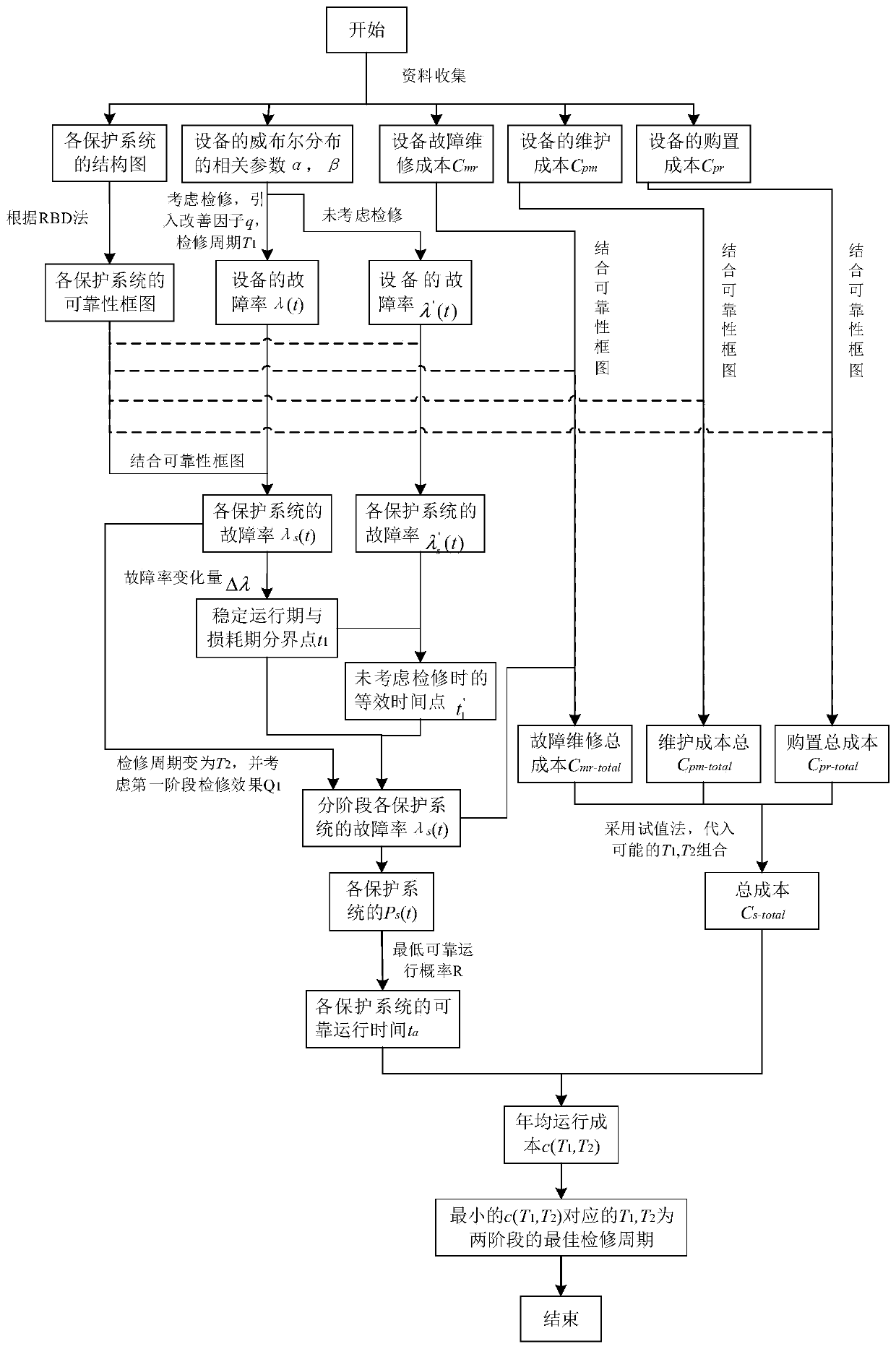

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

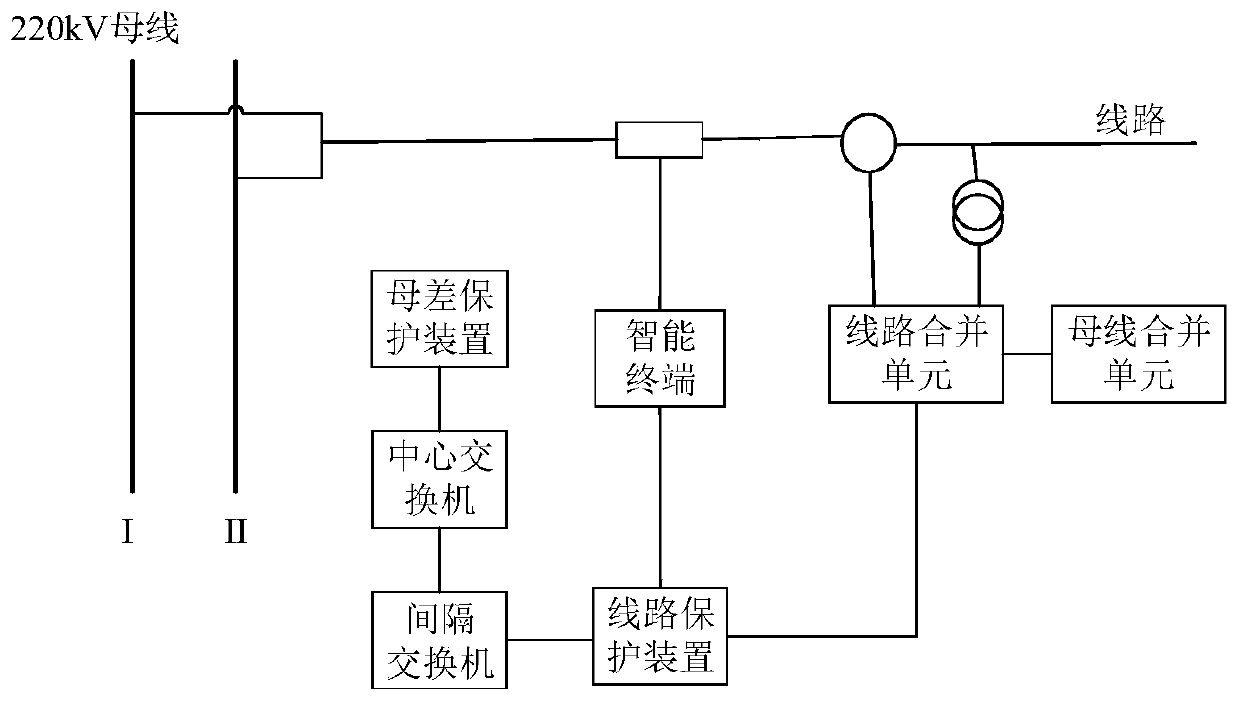

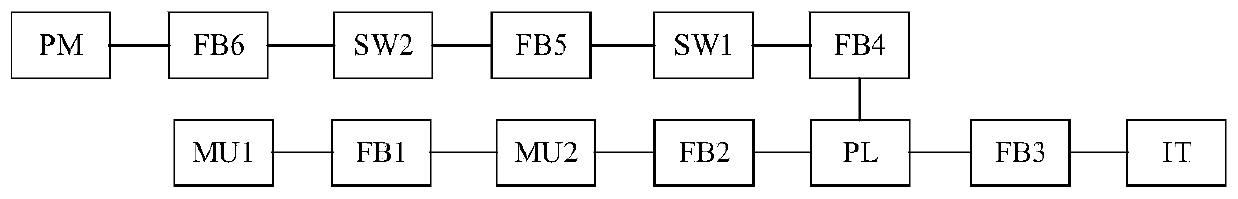

Embodiment

[0195] Based on the built model, the simulation is carried out on the MATLAB2014 software platform, and the corresponding simulation parameter settings are set. The simulation parameters are shown in Table 1:

[0196] Table 1 Simulation parameter table

[0197]

[0198] Since there is no uniform standard for the equipment purchase cost and maintenance cost of protection related equipment, this paper adopts the experience value of equipment purchase cost and breakdown maintenance (B type maintenance) cost provided by a certain manufacturer, and refers to relevant materials to classify C, D, A The cost of the class is set. General maintenance includes categories C and D. The type of maintenance in stable operation is category D, and the type of maintenance in the wear-out period is category C. The maintenance cost of category C is 1.5 times the maintenance cost of category D; the overhaul in stable operation and wear-out period is A The maintenance cost of category D is 2.5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com