A method for calibrating the start and alarm points of clocks and watches

A calibration method and technology for watches and clocks, applied in the field of watches and clocks, can solve problems such as low work efficiency, inability to guarantee objective accuracy, slow adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

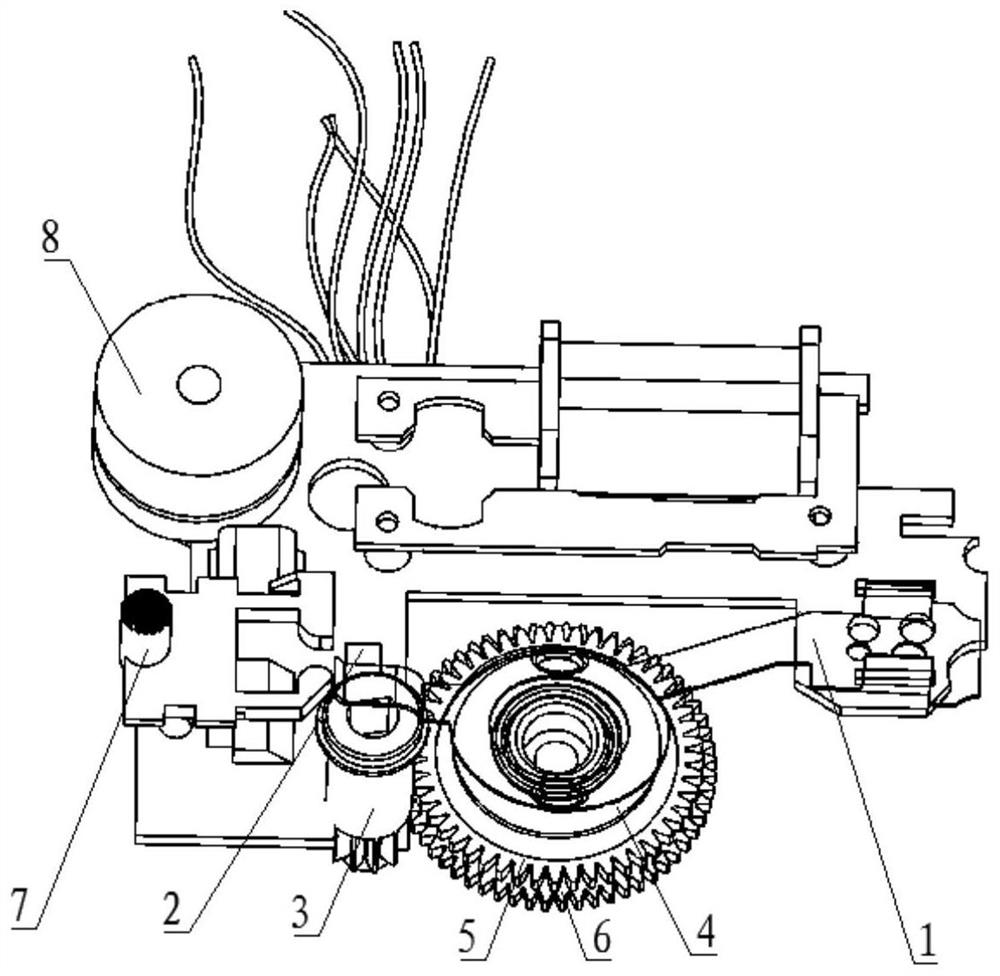

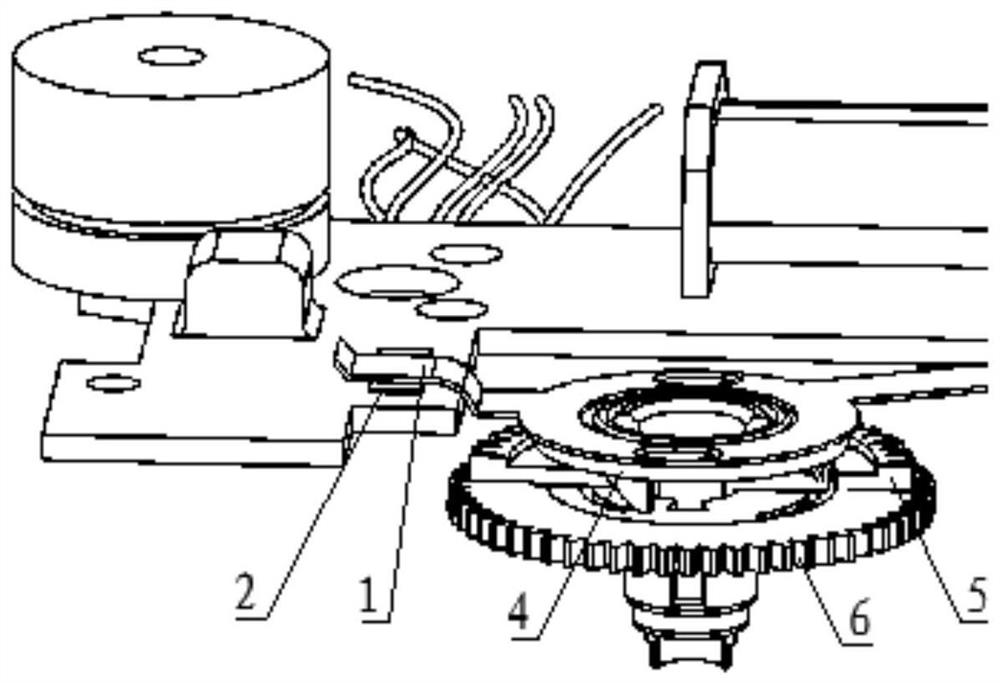

[0045] Please refer to Figure 1-4 , Embodiment 1 of the present invention is:

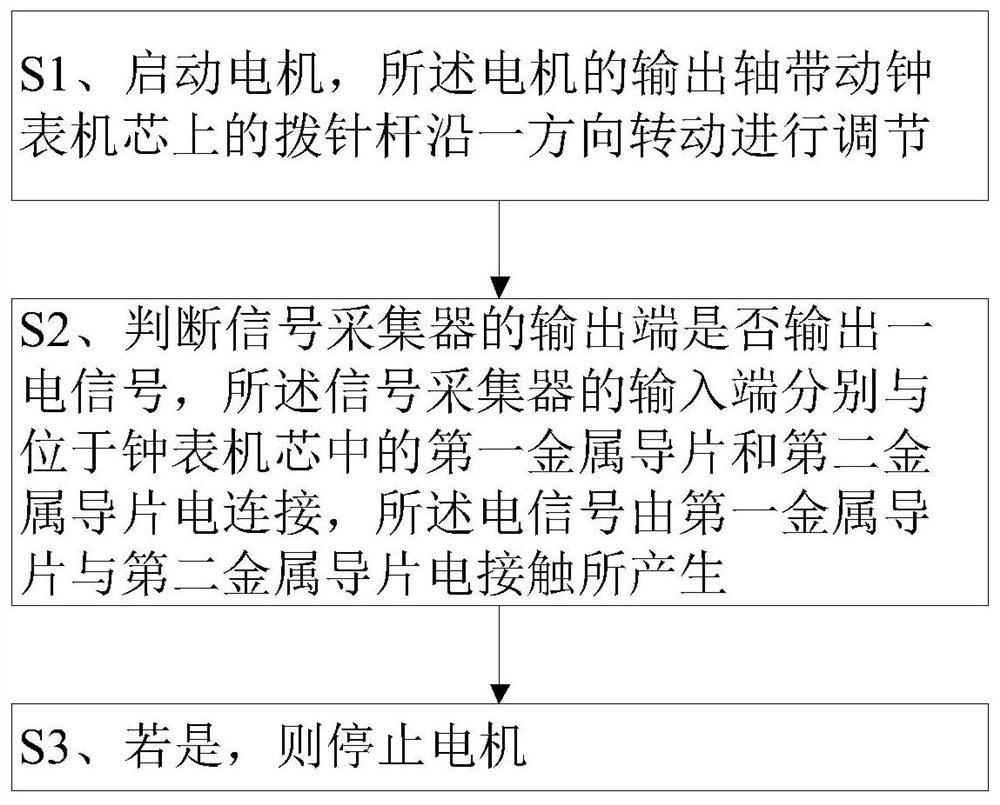

[0046] The invention provides a method for calibrating clock start and alarm points, comprising the following steps:

[0047] S1, start the motor, the output shaft of the motor drives the needle lever on the watch movement to rotate in one direction to adjust, specifically to adjust the position parameters of the internal transmission gear set of the watch movement; the one direction is clockwise or Counterclockwise, preferably clockwise.

[0048] S2, judging whether the output terminal of the signal collector outputs an electrical signal, the input terminal of the signal collector is respectively electrically connected with the first metal guide piece and the second metal guide piece located in the watch movement, and the electrical signal is obtained by Generated by electrical contact between the first metal guide and the second metal guide; the electrical signal is one or more of sine wave, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com