Rolling bearing cage sliding research experiment system

A technology of rolling bearing and experimental system, applied in the direction of mechanical bearing testing, etc., can solve the problems such as difficulty in detecting the slip rate of rolling bearing cage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

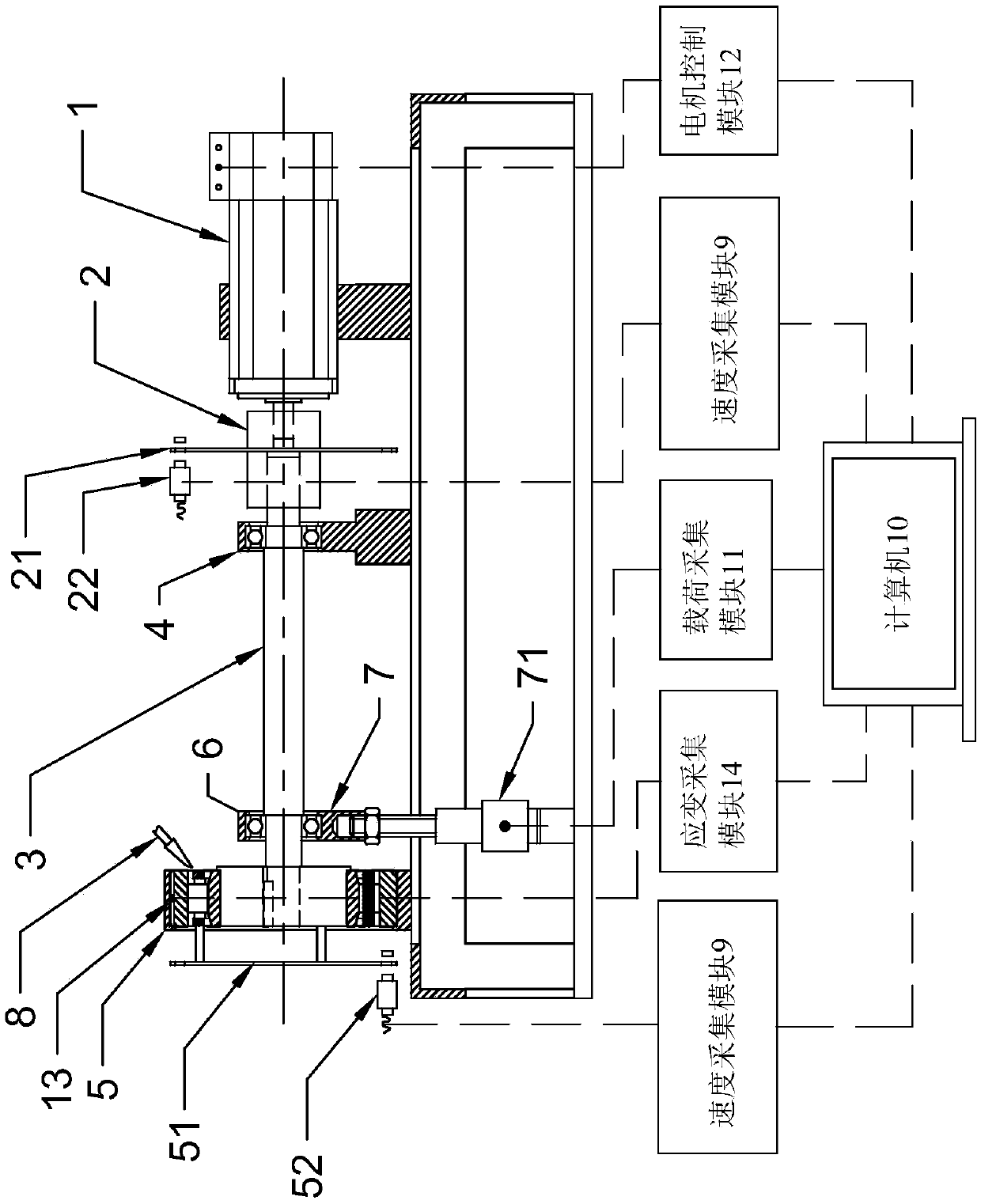

[0056] Such as figure 1 Shown is a schematic structural view of the rolling bearing cage slip research experimental system provided by the present invention, which includes:

[0057] Test bench, used as a fixed foundation for other components of the seat;

[0058] DC speed-regulating motor 1 is fixed on the test bench, and its speed range is preferably 0-3000 rpm;

[0059] The shaft coupling 2 is connected to the DC speed regulating motor 1, and is connected with a first code disc 21, corresponding to the first code disc 21 is provided with a first speed sensor 22 for detecting the rotational speed of the following test spindle 3;

[0060] The test spindle 3 is connected to the DC speed regulating motor 1 through the coupling 2;

[0061] The support bearing 4 is fixed on the test bench, and is used to support and fix the radial position of one end of the test spindle 3;

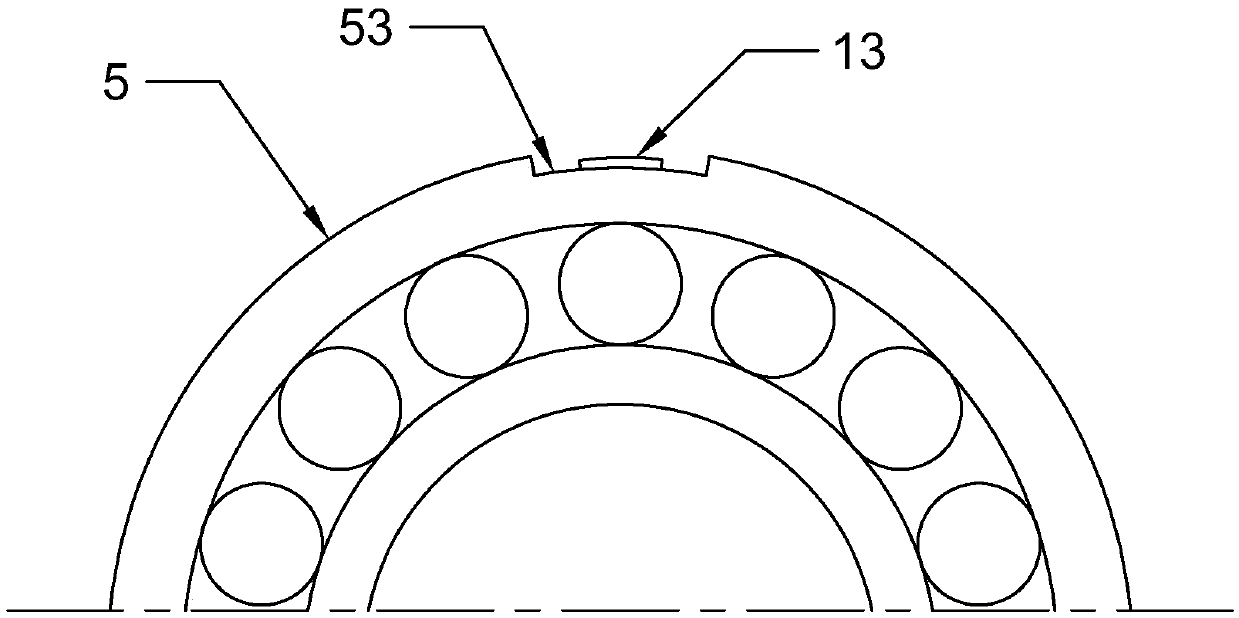

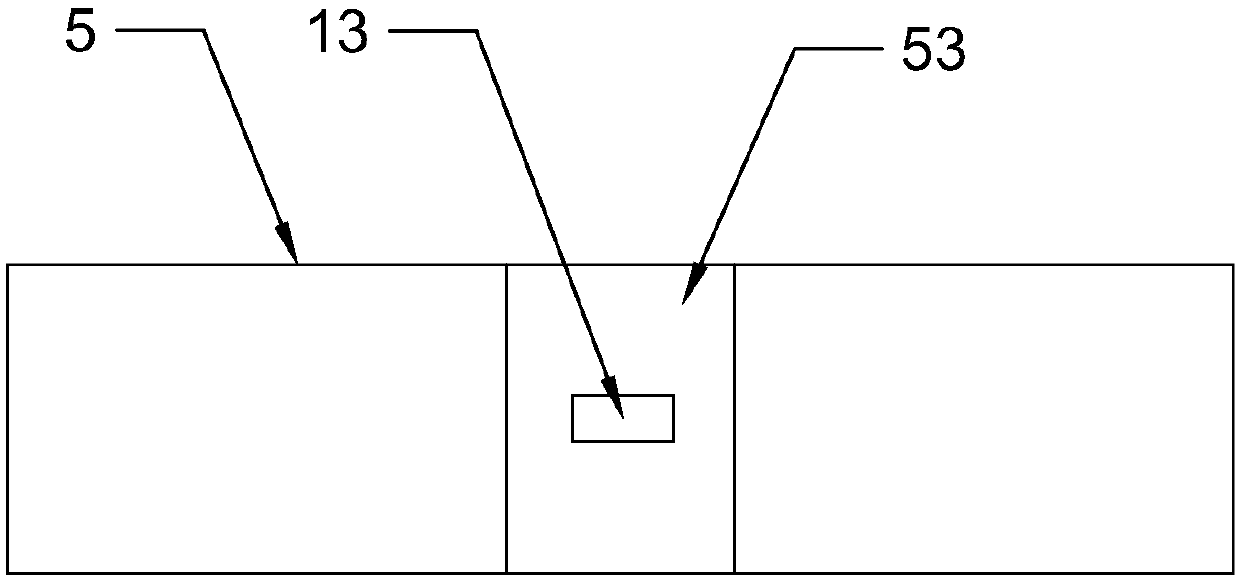

[0062] Test bearing 5, its outer ring is fixed, its inner ring is fixed on the other end of described t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com