Sodium hyaluronate hydrogel with fast curing function and preparing method thereof

A sodium hyaluronate and rapid curing technology, applied in the field of biomedical engineering, can solve the problems of low acylation rate of products, unfavorable for 3D printing, prolonged reaction time, etc., achieve high acylation rate and reduce the possibility of organic residues , the effect of short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

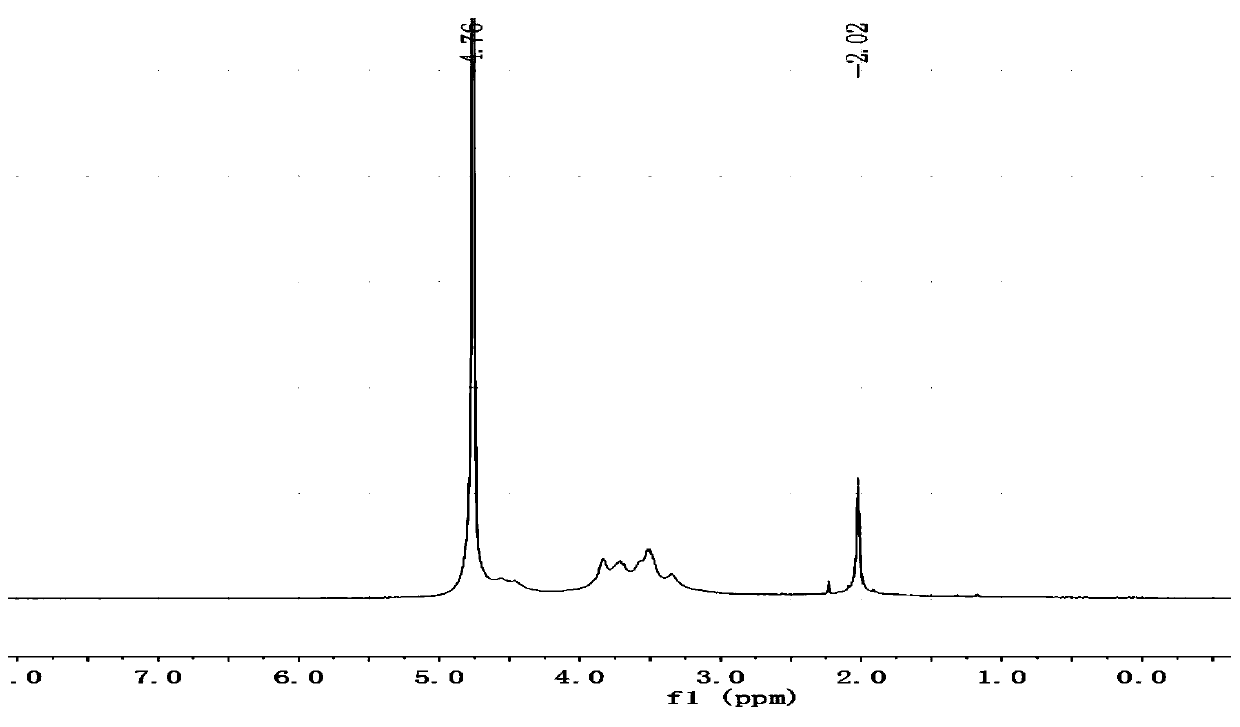

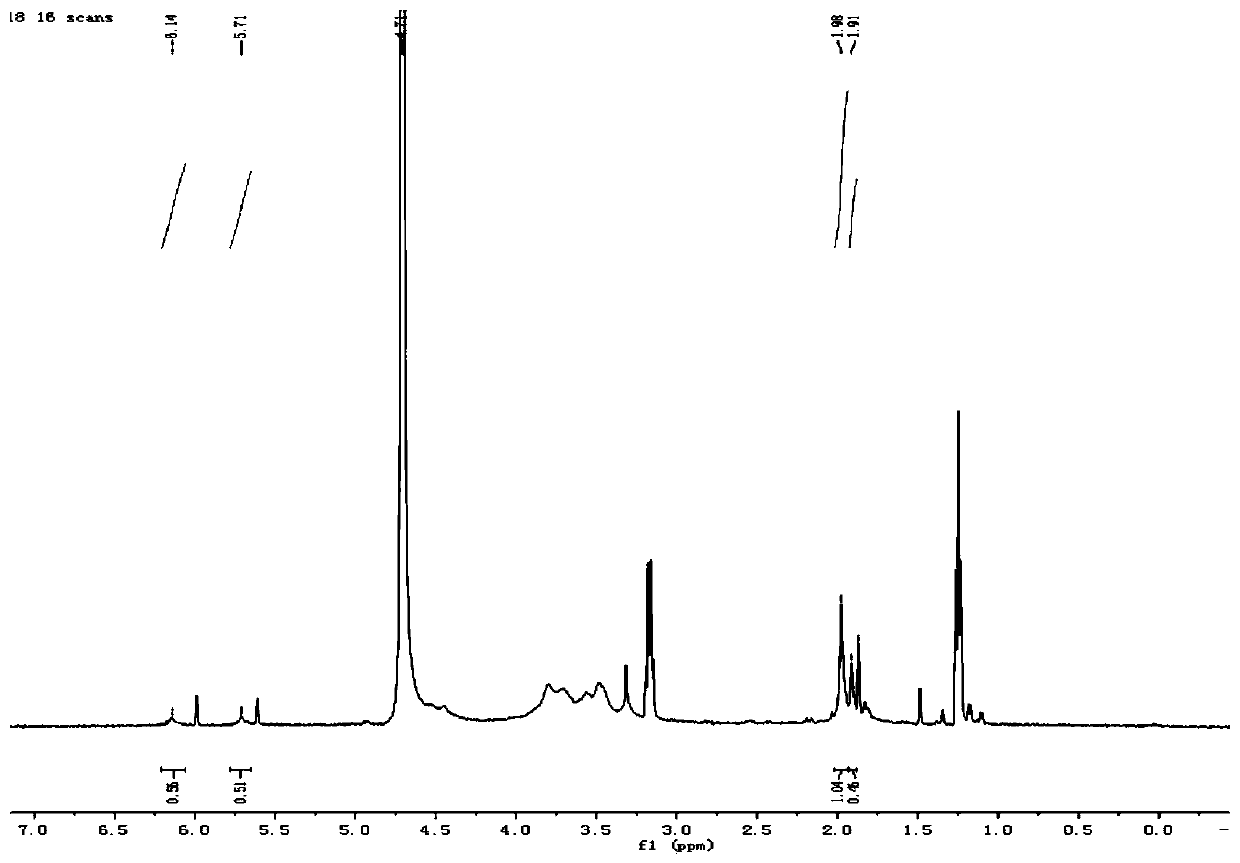

Image

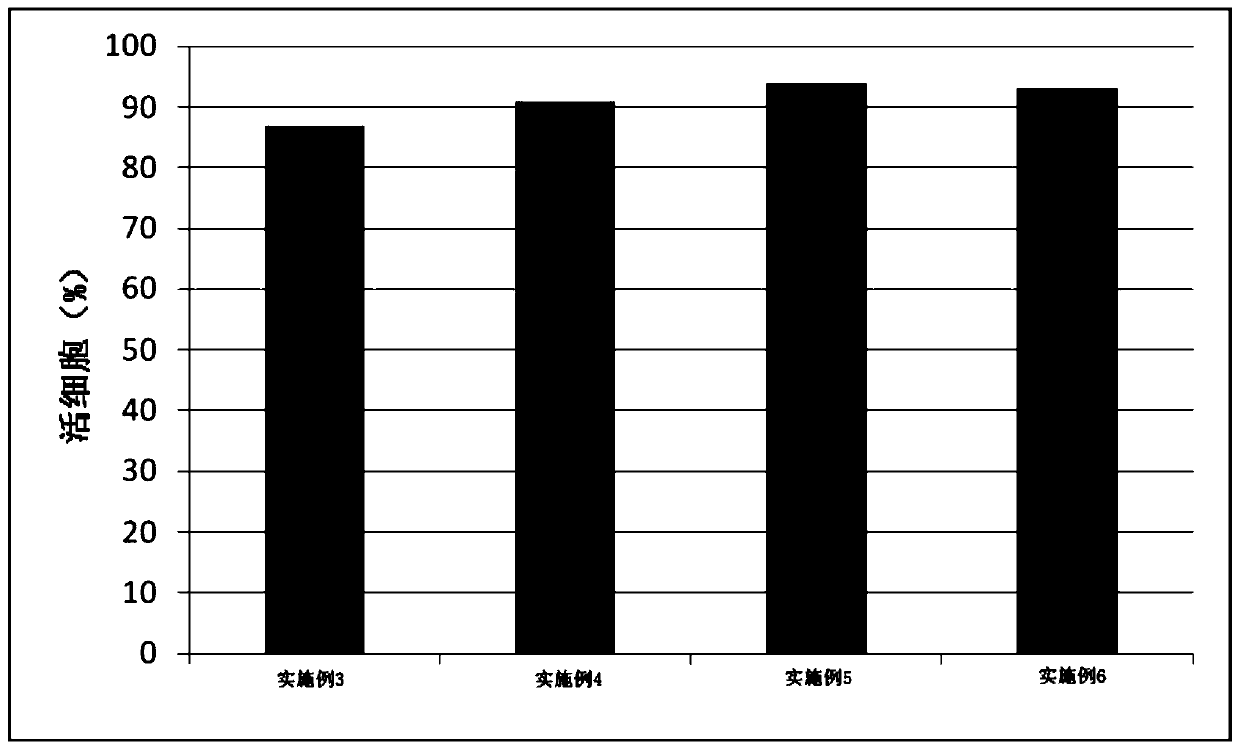

Examples

Embodiment 1

[0031] A sodium hyaluronate hydrogel with rapid curing function, in terms of mass percentage, the sodium hyaluronate hydrogel comprises 7% sodium hyaluronate, 4% methacrylic anhydride, and 0.5% photoinitiator , 3% alkaline buffer solution, and the balance is deionized water.

Embodiment 2

[0033] A sodium hyaluronate hydrogel with rapid curing function, in terms of mass percentage, the sodium hyaluronate hydrogel comprises 8% sodium hyaluronate, 5% methacrylic anhydride, and 0.9% photoinitiator , 5% alkaline buffer solution, and the balance is deionized water.

Embodiment 3

[0035] A preparation method of sodium hyaluronate hydrogel, the preparation method comprising the steps of:

[0036] S01. Accurately weigh 2 g of sodium hyaluronate, measure 200 ml of 1 mol / mL sodium bicarbonate-sodium carbonate buffer solution, add the weighed sodium hyaluronate, stir until dissolved, and obtain a sodium hyaluronate solution. The pH of the sodium bicarbonate-sodium carbonate buffer is 8-8.5. The temperature of the alkaline buffer solution is 4°C, and the stirring time is 40 min.

[0037] S02. Add 5ml of methacrylic anhydride to the sodium hyaluronate solution, and obtain a reaction solution after the reaction is completed. The reaction condition of the hydroxyl group on the molecular chain of sodium hyaluronate and methacrylic anhydride is to avoid light, the reaction temperature is 24° C., and the reaction time is 16 hours.

[0038] S03. Pour the reaction solution into 800ml of absolute ethanol, precipitate, and filter to obtain a precipitate. Wherein, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com