Closed type torsion beam

A closed and cross-beam technology, which is applied in the field of auto parts, can solve the problems of low first-order mode, heavy spring disc mass, and low service life, and achieve the effects of simple and compact structure, improved torsional stiffness, and reduced local stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with accompanying drawing:

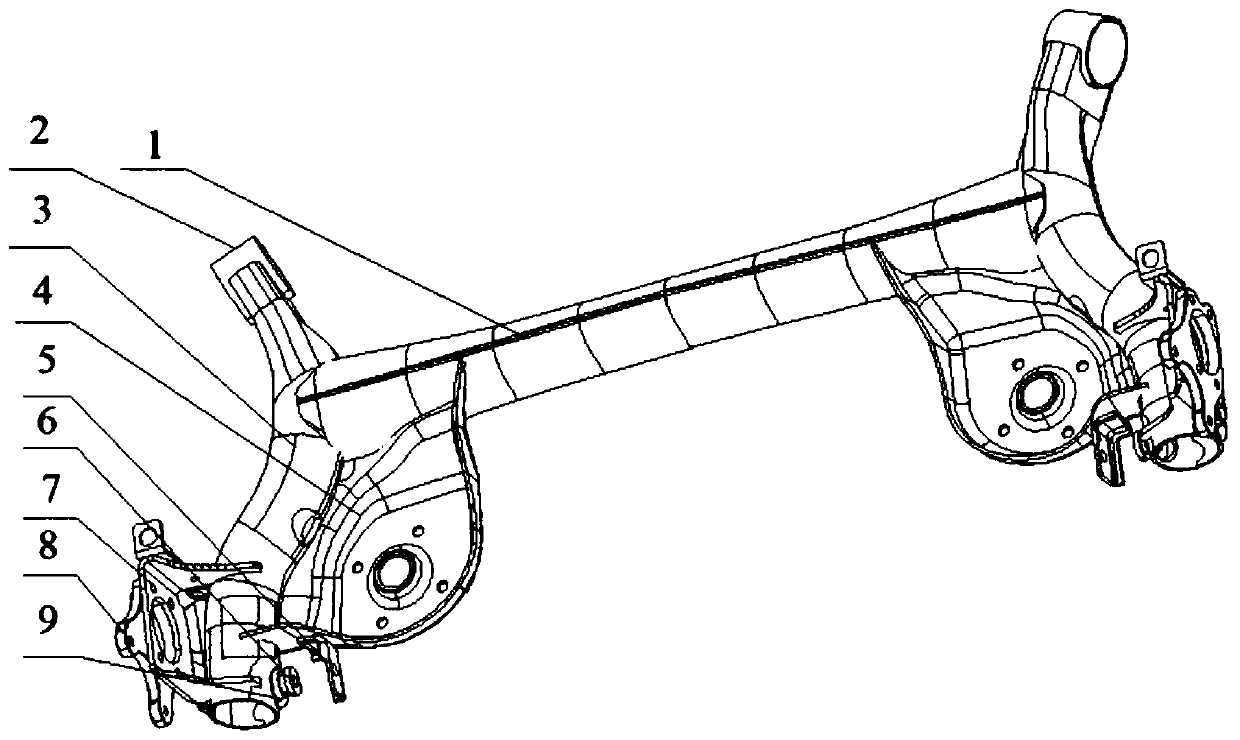

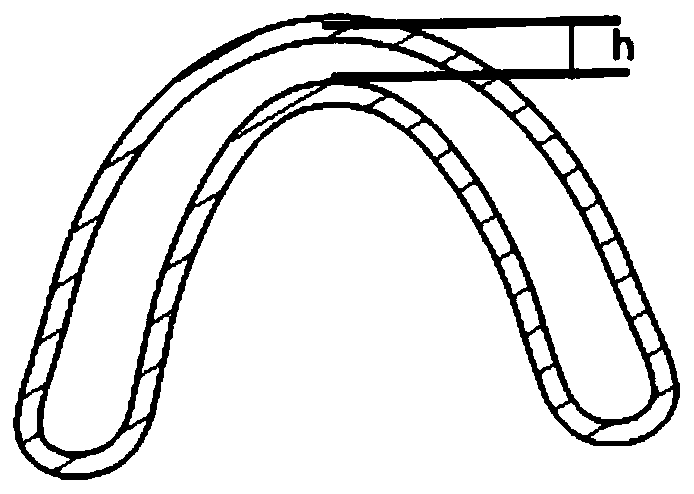

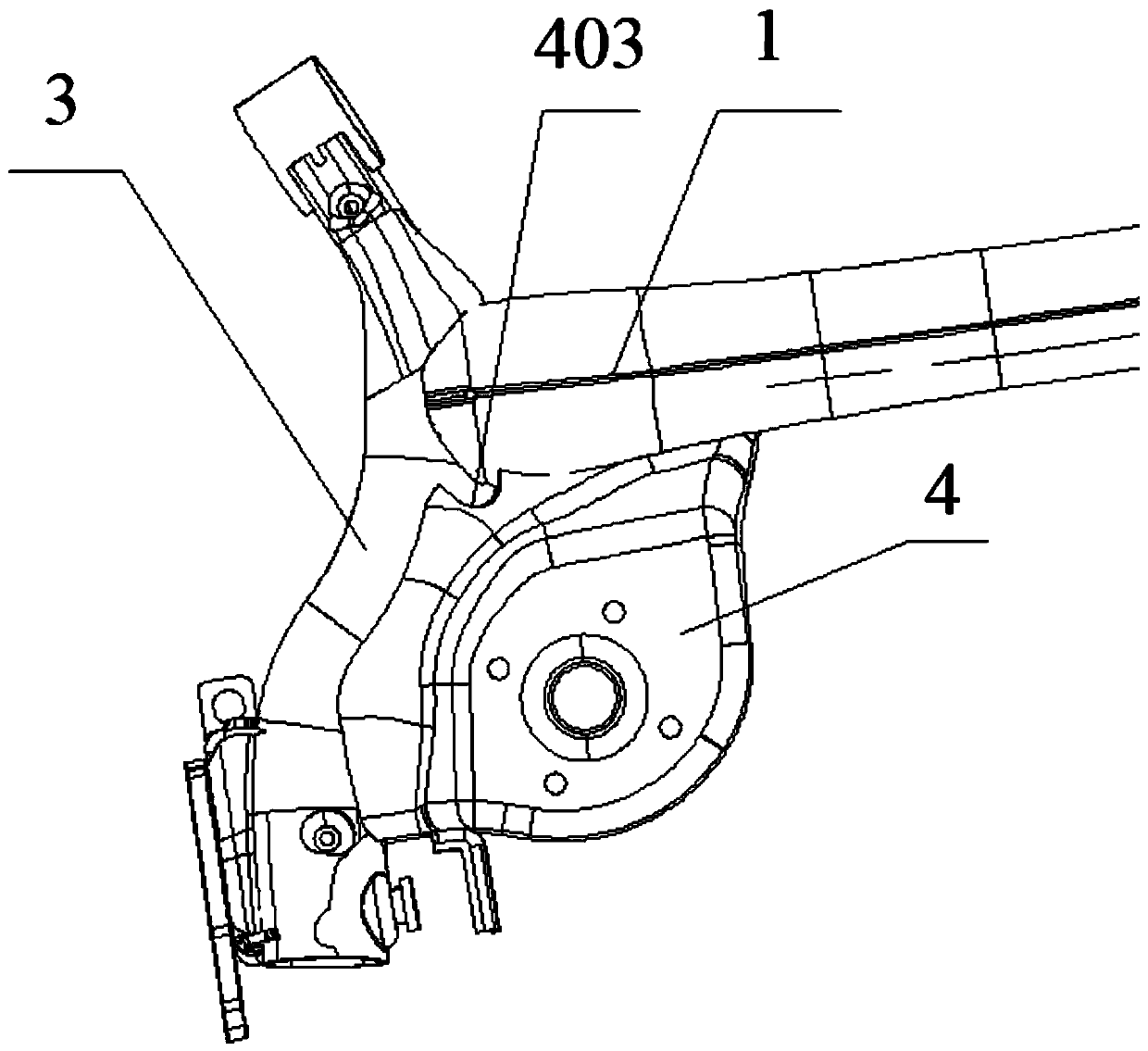

[0020] Embodiment: As shown in the accompanying drawings, this closed torsion beam mainly includes a beam 1, a casing 2, a longitudinal arm 3, a spring plate 4, and a hub bracket 7. Both ends of the beam 1 are fixedly connected with a longitudinal arm 3, The bushing 2 is set on the side of the longitudinal arm 3 that is closer to the crossbeam 1, the spring plate 4 is respectively connected and fixed with the crossbeam 1 and the longitudinal arm 3, the rear part of the spring plate 4 is fixed with a bracket A5, and the rear end of the longitudinal arm 3 is provided with a convex There are holes on the platform 9 and the boss 9, and a circular bracket B6 is arranged in the hole. The position of the bracket B6 corresponds to the bracket A5 and together constitutes the shock absorber installation bracket. 1 On the far side, the hub bracket 7 is also provided with a rabbit-ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com