Field-induced reversible nonlinear conductive composite material preparation method, prepared material and application

A conductive composite material, nonlinear technology, applied in field-induced reversible nonlinear conductive composite material manufacturing method, the field of materials prepared, can solve the problems of unstable nonlinear conductive characteristics, poor electromagnetic pulse protection performance, diode delay time, etc. , to achieve excellent electrical conductivity, easy mass production, and stable thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

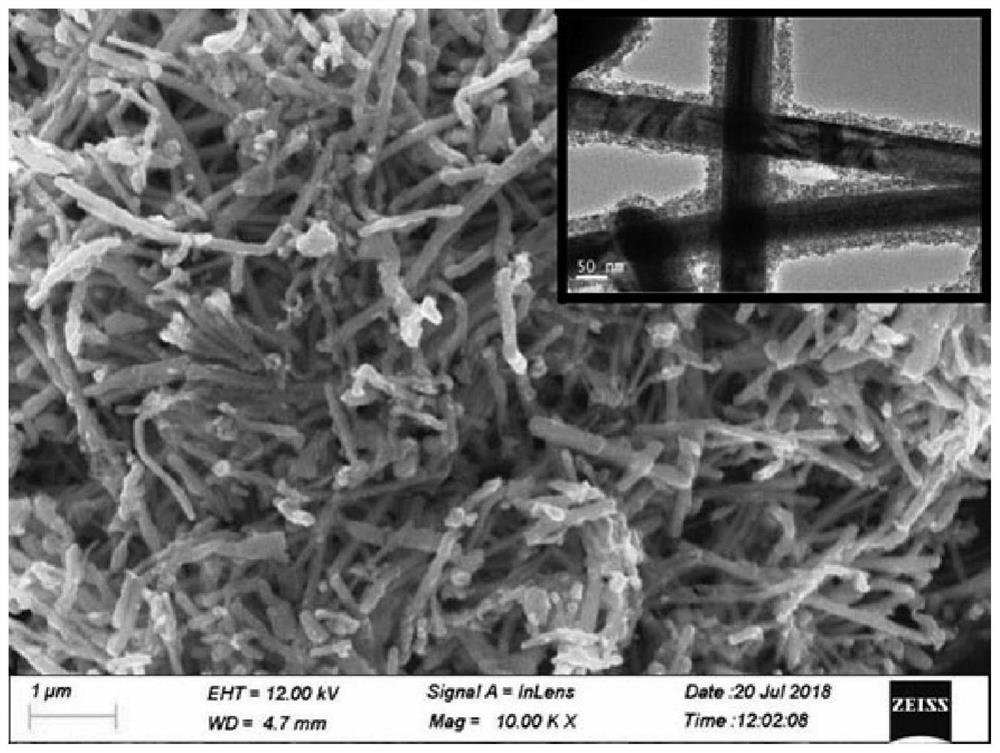

[0042] The preparation method of the field-induced reversible nonlinear conductive composite material comprises the following steps:

[0043] (1) First, weigh 0.8 g of PVP and add it to 100 ml of EG and stir for 4 to 5 hours until it is completely dissolved to obtain a mixed solution A.

[0044] (2) After that, weigh 1g of AgNO 3 And add to solution A and stir well for about 1 hour until completely dissolved to obtain solution B.

[0045] (3) Then, add 14ml of 600μM FeCl to Solution B 3 / EG solution and stirred for about 5 minutes to obtain solution C.

[0046] (4) Pour the uniformly stirred solution C into a 500ml round-bottomed flask and heat in an oil bath at 130°C for 5 hours. Solution C in the round-bottomed flask gradually darkened from light yellow to brown, and finally turned milky white, forming milky white suspension D. After the reaction is complete, wait for the milky white suspension D to cool down to room temperature naturally, take it out and pour it into a ...

Embodiment 2

[0051] The preparation method of the field-induced reversible nonlinear conductive composite material comprises the following steps:

[0052] Front (1)-(6) is the same as embodiment 1.

[0053] (7) First weigh 5 g of PVA (the degree of polymerization is 1750±50, the degree of alcoholysis is 99%) and 90ml of deionized water are placed in a round bottom flask, and stirred magnetically for half an hour at room temperature to volatilize the impurities and make the PVA Sufficient swelling to avoid skin ingrowth during dissolution. Then increase the temperature, heat deionized water to 90 °C, and continue stirring for about 1.5 h until the PVA is completely dissolved to obtain solution G. Take 8 parts of AgNWs@TiO prepared in step (6) 2 (Among them, 1 part of AgNWs@TiO prepared in step (6) 2 Refers to the AgNWs@TiO obtained from 1 part of AgNWs prepared in step (5) and then treated in step (6) 2 Composite particles) were added to solution G, the temperature was adjusted to 65°C, ...

Embodiment 3

[0055] The preparation method of the field-induced reversible nonlinear conductive composite material comprises the following steps:

[0056] Front (1)-(6) is the same as embodiment 1.

[0057] (7) First weigh 5 g of PVA (the degree of polymerization is 1750±50, and the degree of alcoholysis is 99%) and 90 ml of deionized water are placed in a round bottom flask, and stirred magnetically for half an hour at room temperature to volatilize impurities and make PVA Sufficient swelling to avoid skin ingrowth during dissolution. Then increase the temperature, heat deionized water to 90 °C, and continue to stir for about 1.5 h until the PVA is completely dissolved to obtain solution G. Take 10 parts of AgNWs@TiO prepared in step (5) 2 (Among them, 1 part of AgNWs@TiO prepared in step (6) 2 Refers to the AgNWs@TiO obtained from 1 part of AgNWs prepared in step (5) and then treated in step (6) 2 Composite particles) were added to solution G, the temperature was adjusted to 65°C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com