Method for preparing azacitidine by high-purity and low-calcination residue

A technology of azacitidine and azacytosine, which is applied in the field of azacitidine synthesis technology, can solve the problems of easy residual metal tin, difficulty in large-scale production, low yield of crude product, etc., to achieve easy quality control and reduce emulsification Phenomenon, the effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

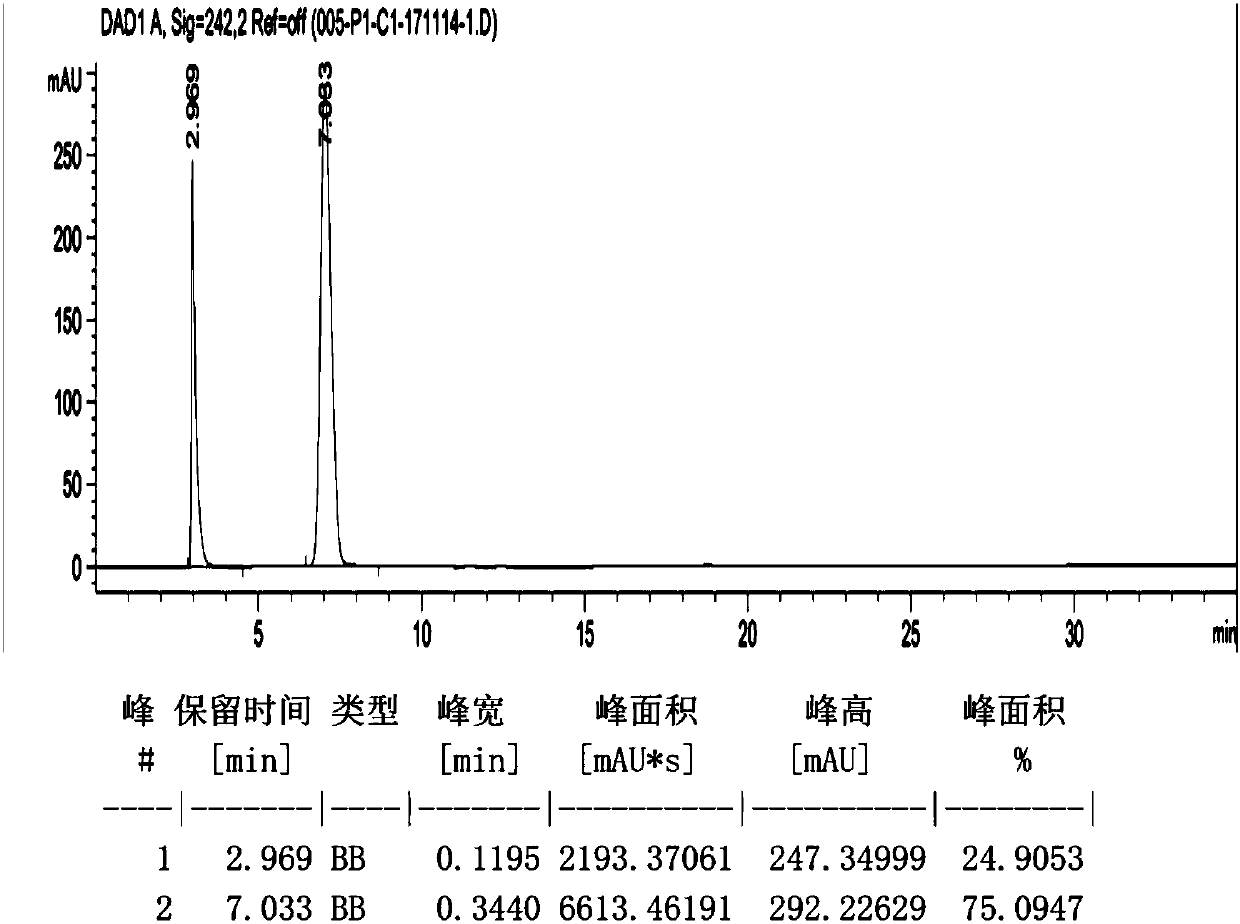

Image

Examples

Embodiment 1

[0044] Preparation of Intermediate 1: Add 5-azacytosine (224g, 2.0mol), HMDS (646g, 4.0mol) and ammonium sulfate (24g, 0.18mol) in a dry 2L round bottom flask, start mechanical stirring and mix, Gradually raise the temperature to 145-150°C to reflux, and the system begins to become clear in about 5 hours. After the reflux reaction was continued for 15 hours, the heating was stopped. When the temperature dropped to 40-50° C., a large amount of white crystals were precipitated. After cooling down to room temperature, suction filtration was performed. The crystals were soaked with 50 ml of HMDS, drained and dried to obtain 492 g of intermediate 1. Yield 96.0%, mp: 136-138°C.

[0045] Preparation of Intermediate 2: Take Intermediate 1 (164g, 0.64mol) prepared by the above method, add tetraacetyl ribose (221.3g, 0.69mol), dissolve in 1250ml of anhydrous dichloromethane, stir well and slowly add TMSOTf (195g, 0.87mol), the reaction system gradually became clear during the dropwise ...

Embodiment 2

[0049] Preparation of Intermediate 1: Same as Example 1.

[0050] Preparation of Intermediate 2: Take Intermediate 1 (164g, 0.64mol) prepared by the above method, add tetraacetyl ribose (221g, 0.69mol), dissolve in 1200ml of anhydrous dichloromethane, stir slowly and drop TMSOTf ( 195g, 0.87mol), the reaction system gradually became clear during the dropwise addition, and reacted overnight at room temperature. Prepare 1000ml of 0.24N dilute hydrochloric acid solution in cold water, add it to the reaction system, and the color of the reaction solution becomes lighter with stirring. After reacting for 45 minutes, slowly add 1700 ml of ice-cold 10% sodium carbonate solution, stir well until the pH is 8-9, and let stand to separate the organic phase and the aqueous phase. The organic phase was washed with ice water, dried over anhydrous sodium sulfate overnight, and concentrated to give Intermediate 2 253 g as a fluffy white solid with a moisture content of 1.8%.

[0051] Prepar...

Embodiment 3

[0053] Embodiment 3 (comparative example)

[0054] Preparation of Intermediate 1: Same as Example 1.

[0055] Preparation of Intermediate 2: Take Intermediate 1 (164g, 0.64mol) prepared by the above method, add tetraacetyl ribose (256g, 0.80mol), dissolve in 1200ml of anhydrous dichloromethane, stir slowly and drop TMSOTf ( 195g, 0.87mol), the reaction system gradually became clear during the dropwise addition, and reacted overnight at room temperature. Take 70g of sodium carbonate, 56g of sodium bicarbonate, 750g of ice and 500g of purified water, mix and stir evenly, pour the reaction solution into the mixture, stir vigorously until no more bubbles are generated, separate the water phase and the organic phase, and use 200ml of distilled water for the water phase. Extract with methyl chloride, combine the organic phases and wash with cold 10% sodium bicarbonate solution and cold saturated brine, and dry over anhydrous sodium sulfate overnight. After concentration and evapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com