An alarm device for agricultural monoammonium phosphate production system

A production system and alarm device technology, applied to ammonium orthophosphate fertilizers, phosphate, alarms, etc., can solve problems such as troubles, high temperature and high humidity in the production environment, and uneven aging speed of ammonia gas detectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

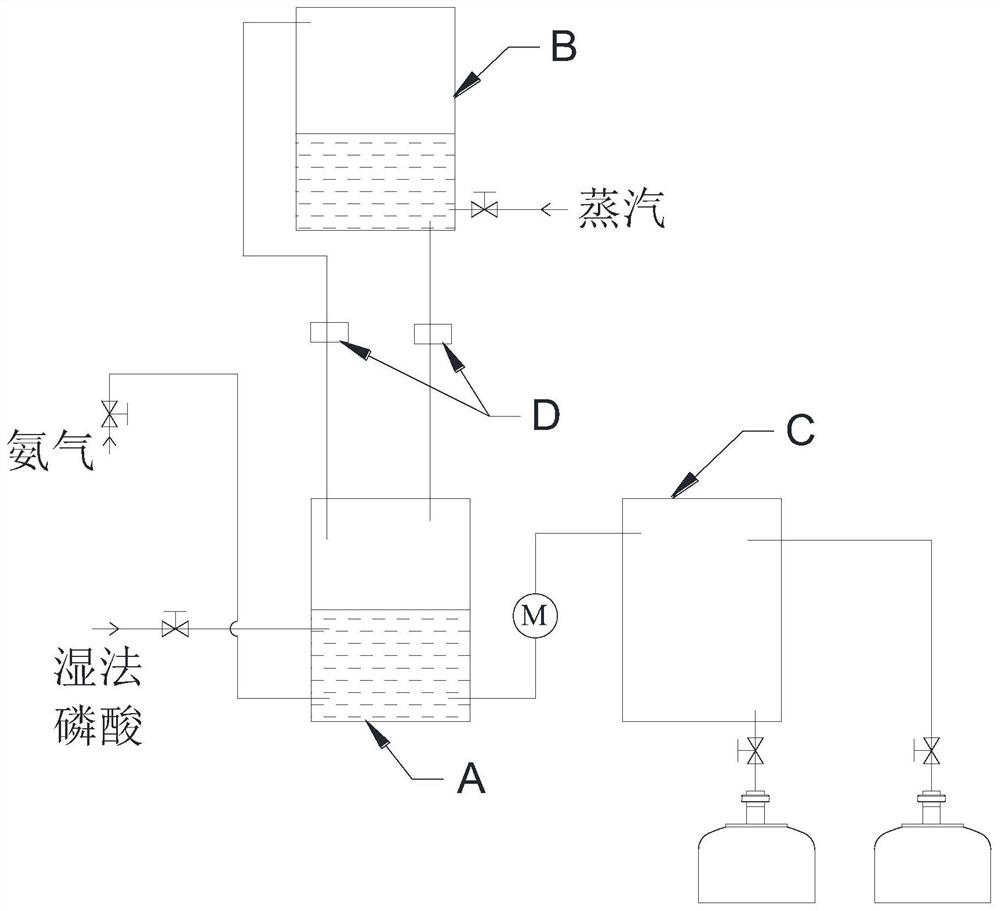

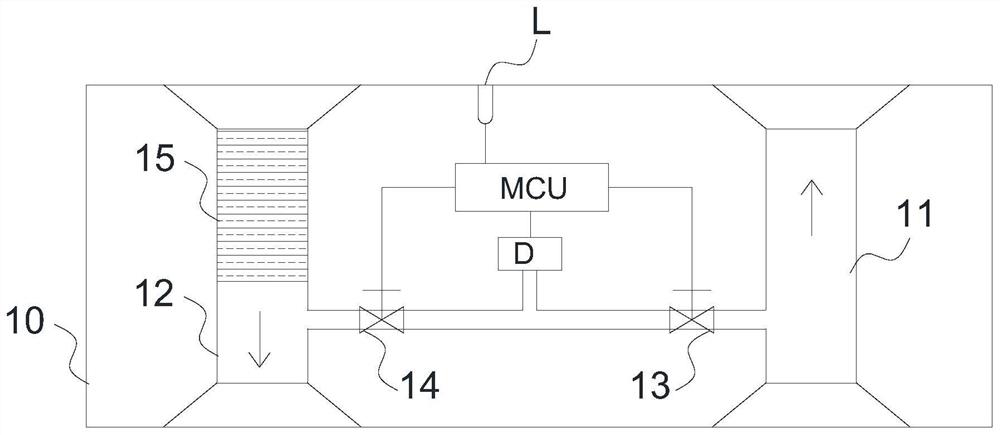

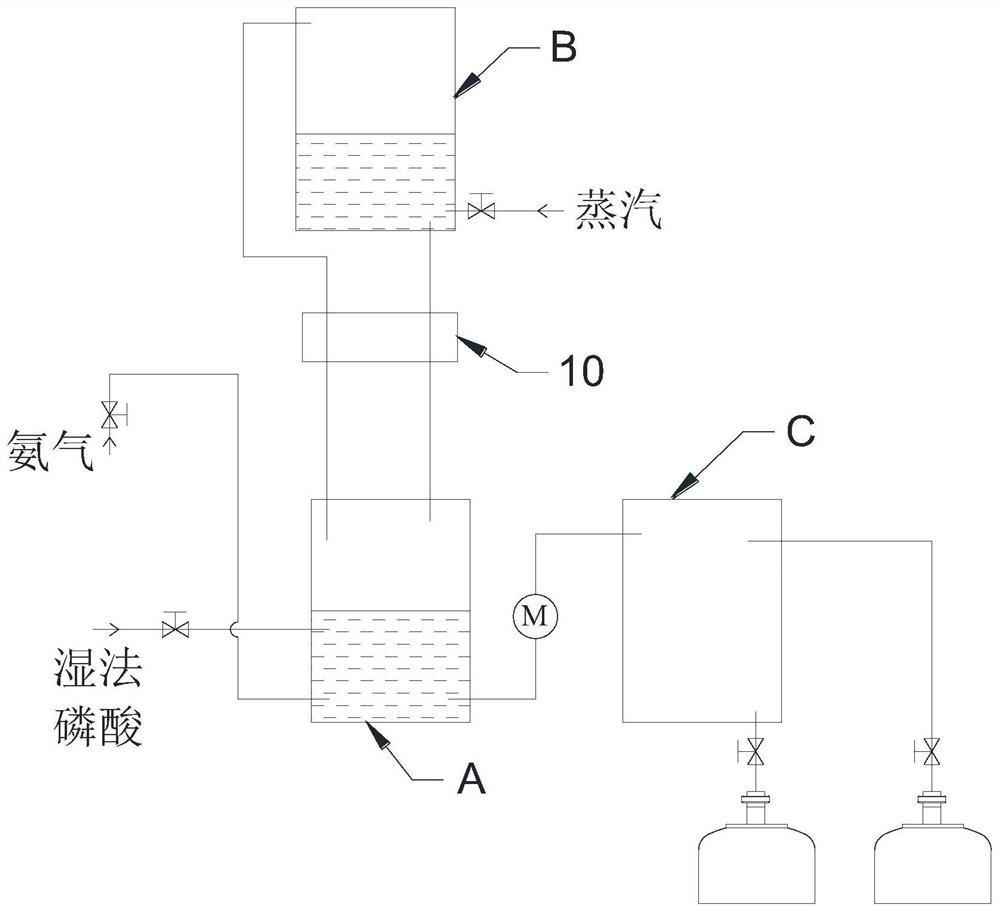

[0016] Such as figure 2 As shown, the alarm device of a kind of agricultural monoammonium phosphate production system of the present invention comprises: a body 10, a first air pipe 11 is provided on one side of the body 10, and a second air pipe 12 is provided on the other side; There is an ammonia detector D and an MCU; the air inlet of the ammonia detector D is communicated with the first air pipe 11 through a branch pipe connected in series with the first electromagnetic valve 13, and the air inlet is also connected in series with the second air pipe 11. The branch pipe of the electromagnetic valve 14 communicates with the second gas pipe 12; the signal output end of the ammonia detector D is connected to the signal input end of the MCU, and the MCU controls the first electromagnetic valve 13 and the second electromagnetic valve 14 to stagger the intermittent On state.

[0017] When the MCU opens the first solenoid valve 13 and closes the second solenoid valve 14, the da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com