Mechanical structure fuzzy fatigue reliability optimization method based on self-constructed membership function

A technology of mechanical structure and membership function, applied in design optimization/simulation, electrical digital data processing, computer-aided design, etc., can solve the problems of low prediction accuracy and calculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

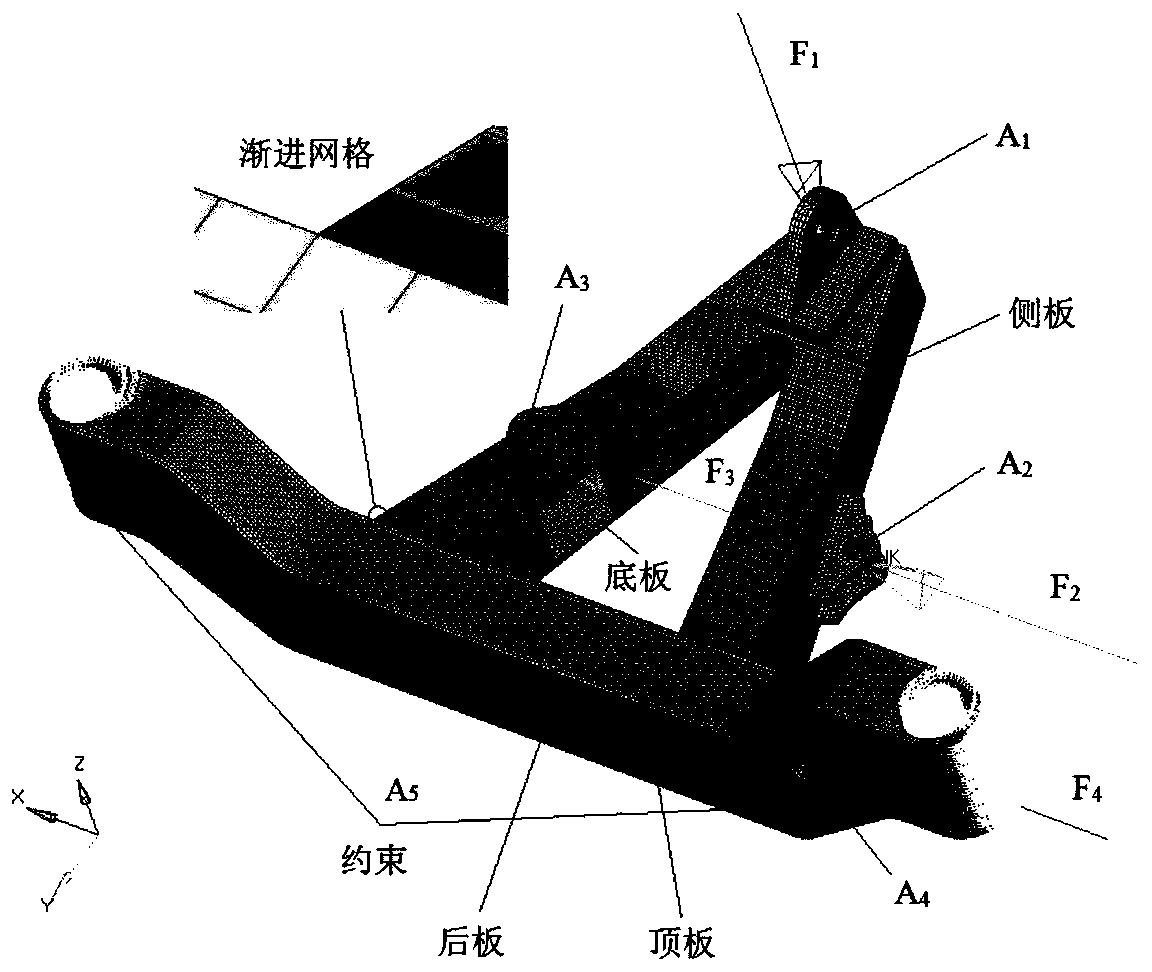

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

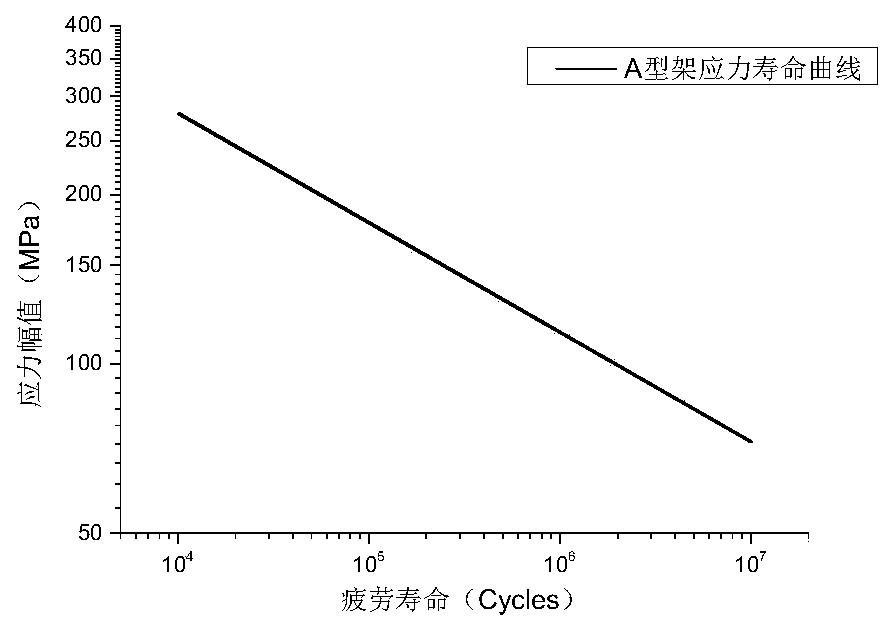

[0054] An example of fuzzy fatigue reliability optimization design based on self-constructed membership function for the A-frame welding mechanical structure of an electric wheel dump truck is given below, but the scope of protection of the present invention is not limited to the following examples.

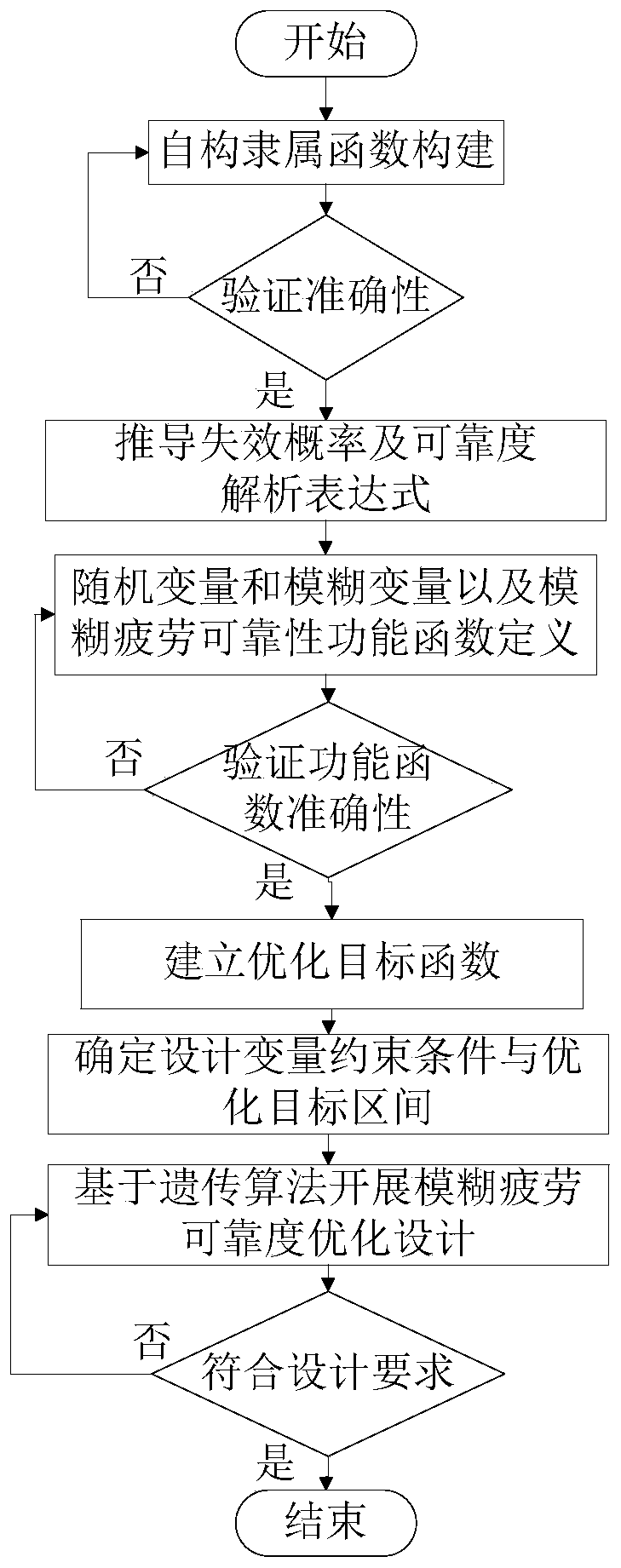

[0055] Step 1: Construct the self-constructed membership function, and after verifying its accuracy, derive the analytical expression of fuzzy fatigue reliability and the analytical expression of fuzzy fatigue failure probability.

[0056] For the A-frame mechanical structure of an electric wheel dump truck, its self-constructed membership function is shown in the following formula:

[0057]

[0058] In the formula: U(S) is the self-constructed membership function, S is the working stress, S r is the fatigue limit, and a is the fuzzy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com