Tunnel lining structure model test device and test method

A technology of structural models and test devices, which is applied in the testing of machines/structural components, measuring devices, testing of mechanical components, etc., can solve problems such as weak, missing mountain rock pressure simulation, and incompletely consistent stress conditions, etc., to achieve The effect of safe test operation, consistency assurance and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

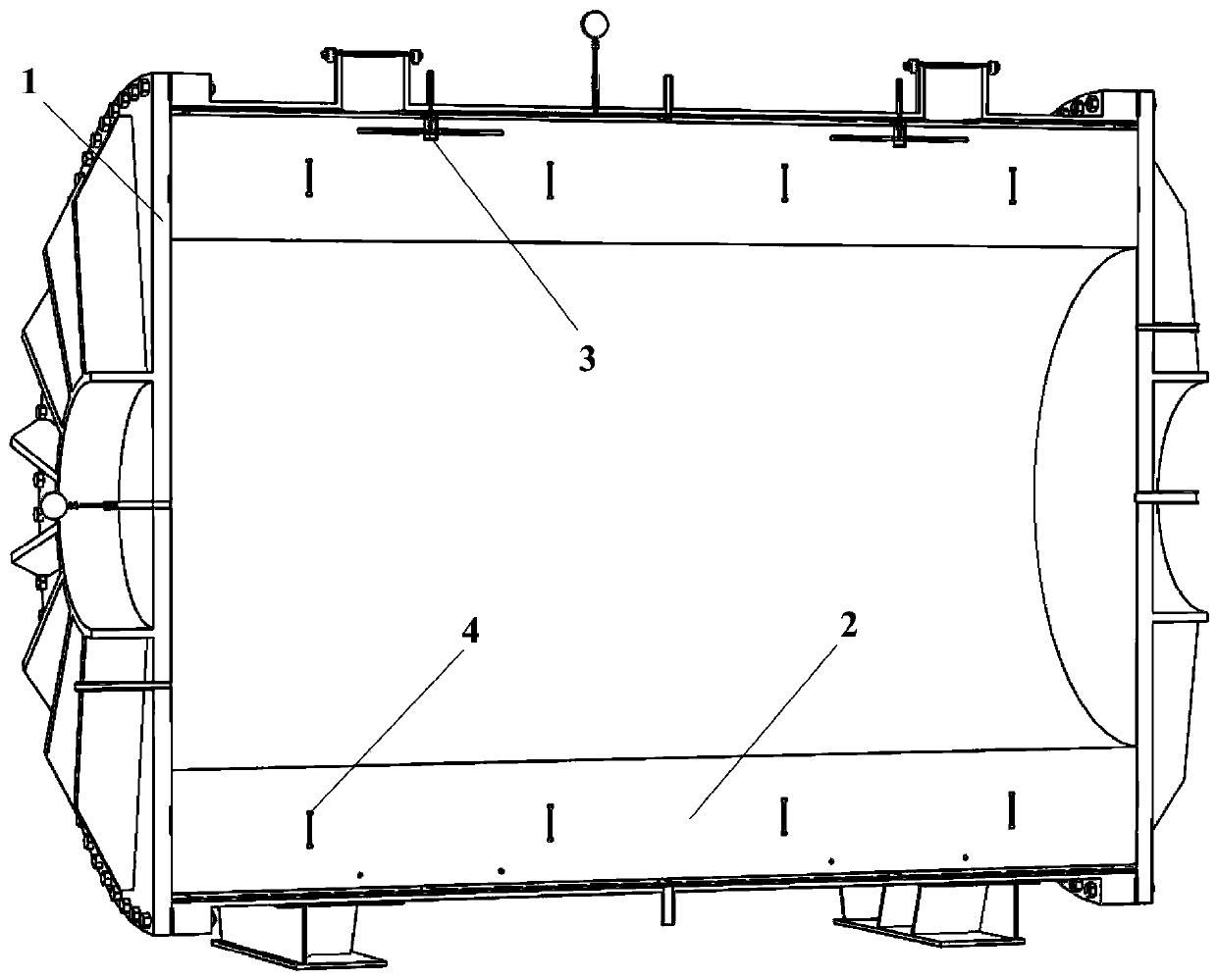

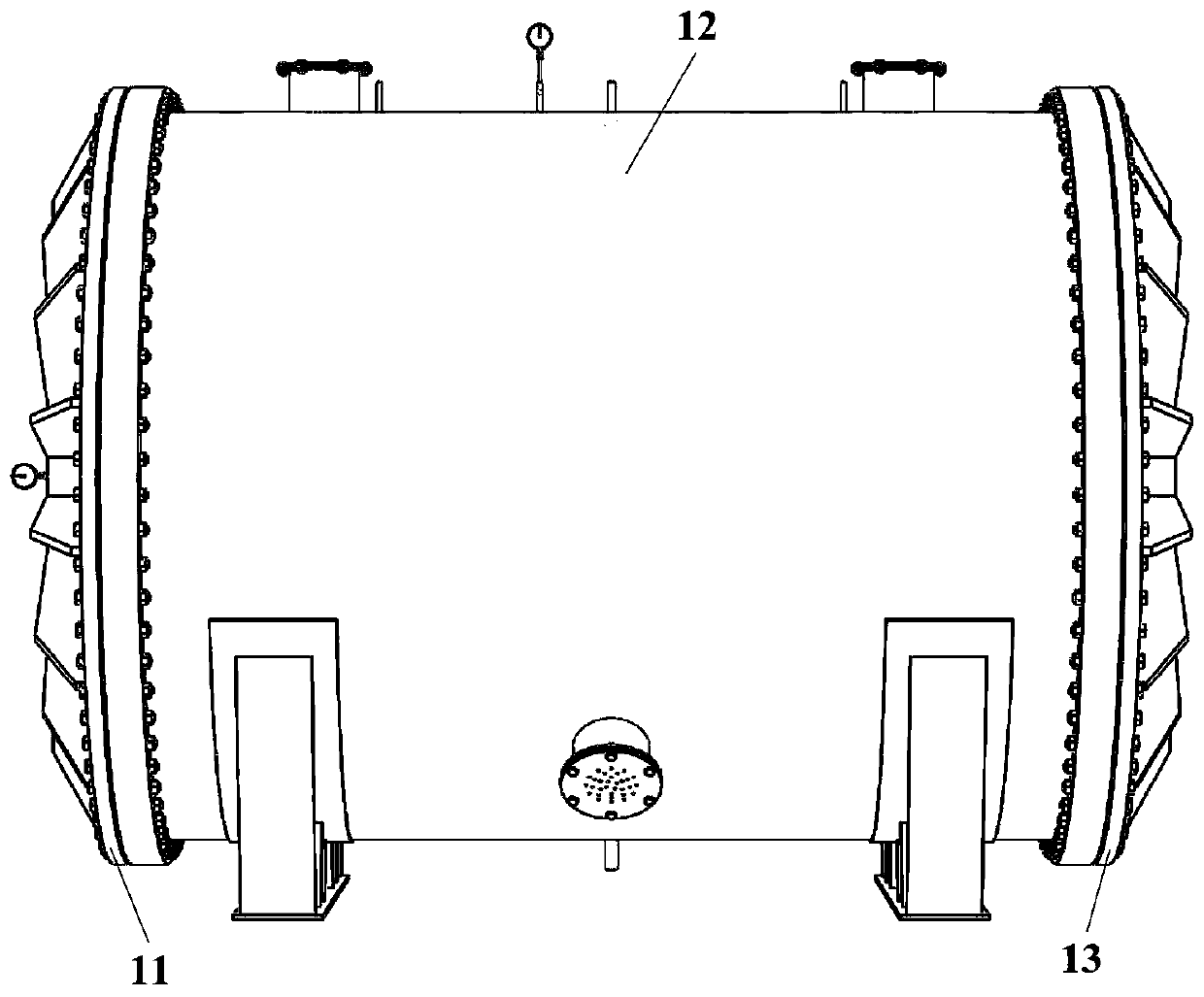

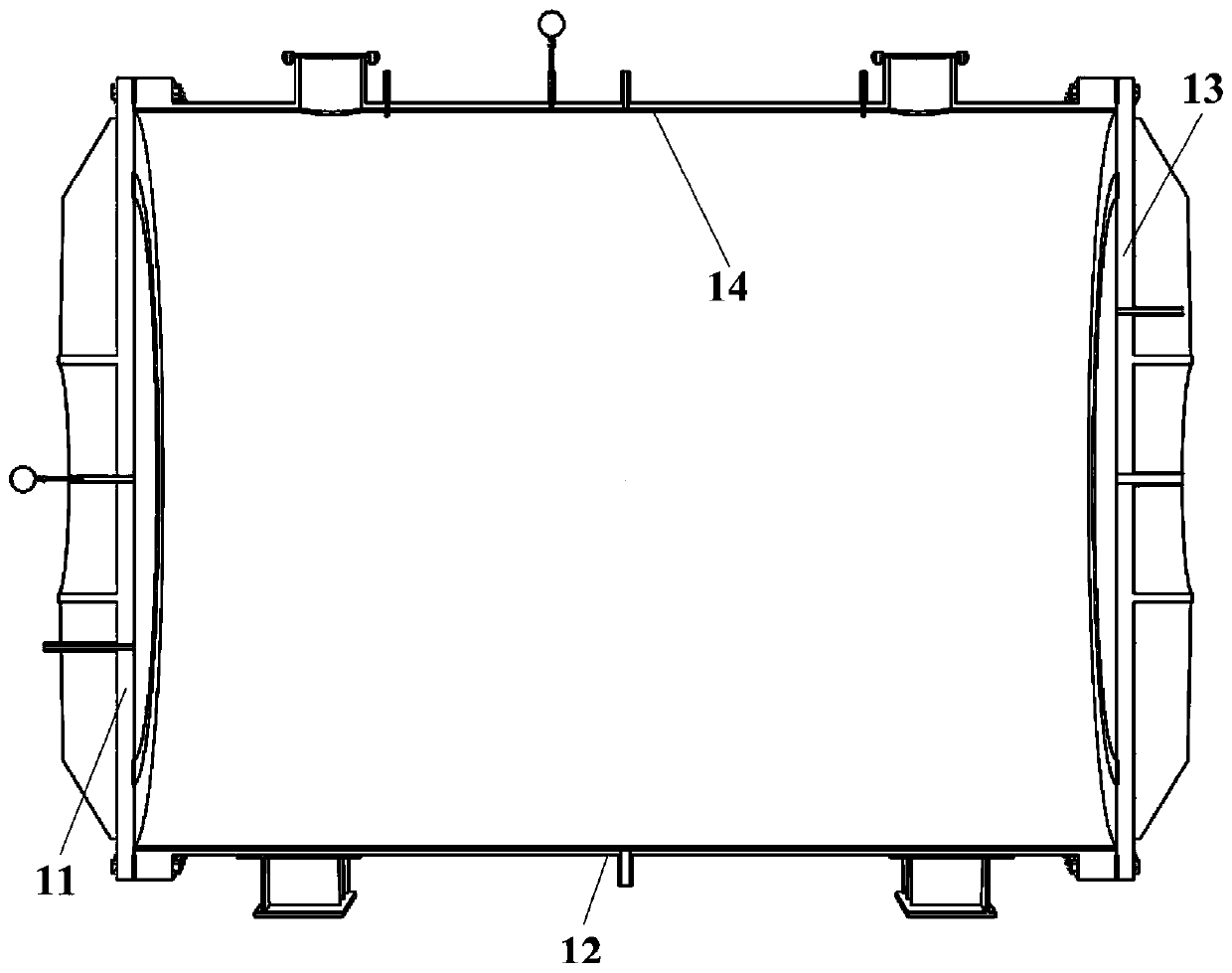

[0053] Embodiment 1: as Figure 1-6b As shown, the tunnel lining structure model test device of the present invention includes a pressure chamber 1 , a lining layer 2 , a stress loading mechanism 3 and a monitoring system 4 . The pressure chamber 1 comprises a front hatch 11, a cabin body 12 and a rear hatch 13. The front hatch 11 is provided with an internal water pressure gauge 111, an inner cavity drain valve 112, an inner sealing ring 113, an outer sealing ring 114, bolts 115, bolts Holes 116 and ribs 117; the cabin body 12 is provided with a stress loading valve external joint 121, a stress loading valve internal joint 122, an external cavity water injection pressure valve 123, a concrete pouring hole 124, an external cavity exhaust valve 125, and an external cavity drainage valve 126. Outer water pressure gauge 127, monitoring instrument cable outlet 128, base 129 and bolt holes 115, filament geotextile 14 is laid on the inner wall of cabin body 12 to prevent concrete fr...

Embodiment 2

[0069] Embodiment 2: The difference from Embodiment 1 is that in Embodiment 2, a surrounding rock simulation layer is also provided between the lining layer 2 and the inner wall of the cabin body 12. The surrounding rock simulation layer is cylindrical in shape as a whole, and is set by the Concrete pouring and molding can simulate different strengths of surrounding rock grades by pouring different grades of concrete. The outer wall of the surrounding rock simulation layer is attached to the inner wall of the cabin body 12, and the two ends of the cylinder body of the surrounding rock simulation layer are flush with the two end surfaces of the cabin body 12.

[0070] A test method for a tunnel lining structure model test device, comprising the following test steps:

[0071] Step 1: Pouring and installing the surrounding rock simulation layer, including:

[0072] Install and fix the rear deck 13, lay the filament geotextile 14 on the inner wall of the cabin body 12, connect the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com