Method for carrying out seismic resistance on flue gas desulfurization building by adopting damper

A damper and flue gas technology, which is applied in the direction of protective buildings/shelters, buildings, building components, etc., can solve the problems of increased material consumption, rigid seismic design, and insufficient structural ductility, etc., to achieve the required space. Reduce building volume, excellent flame retardant performance and anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

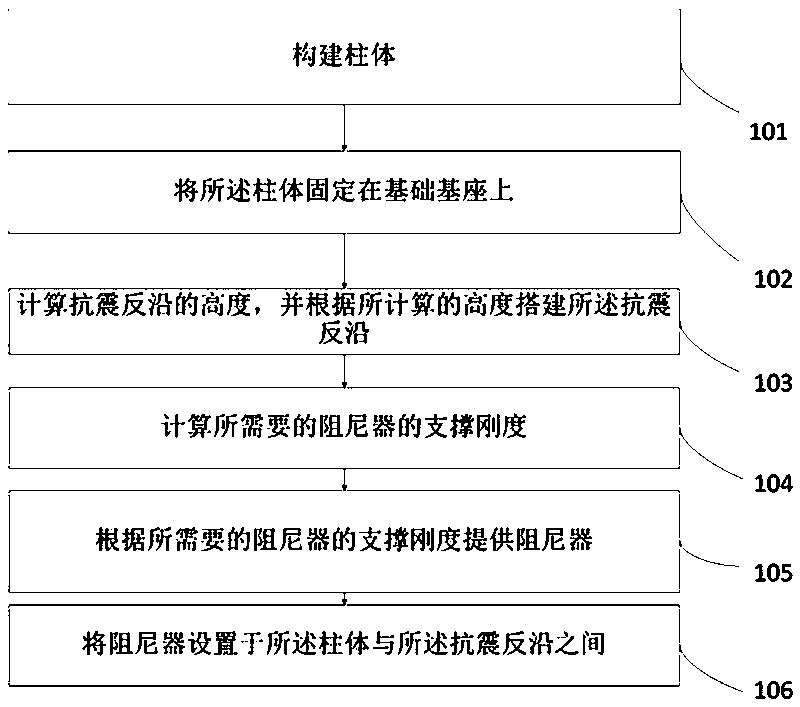

Method used

Image

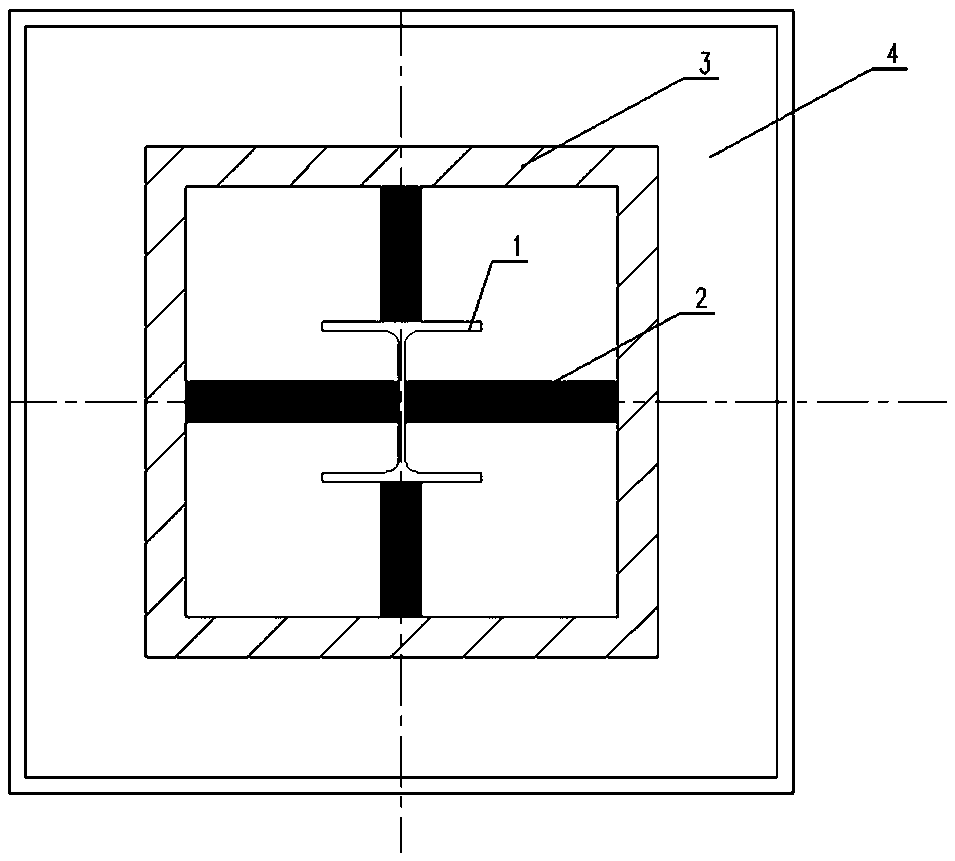

Examples

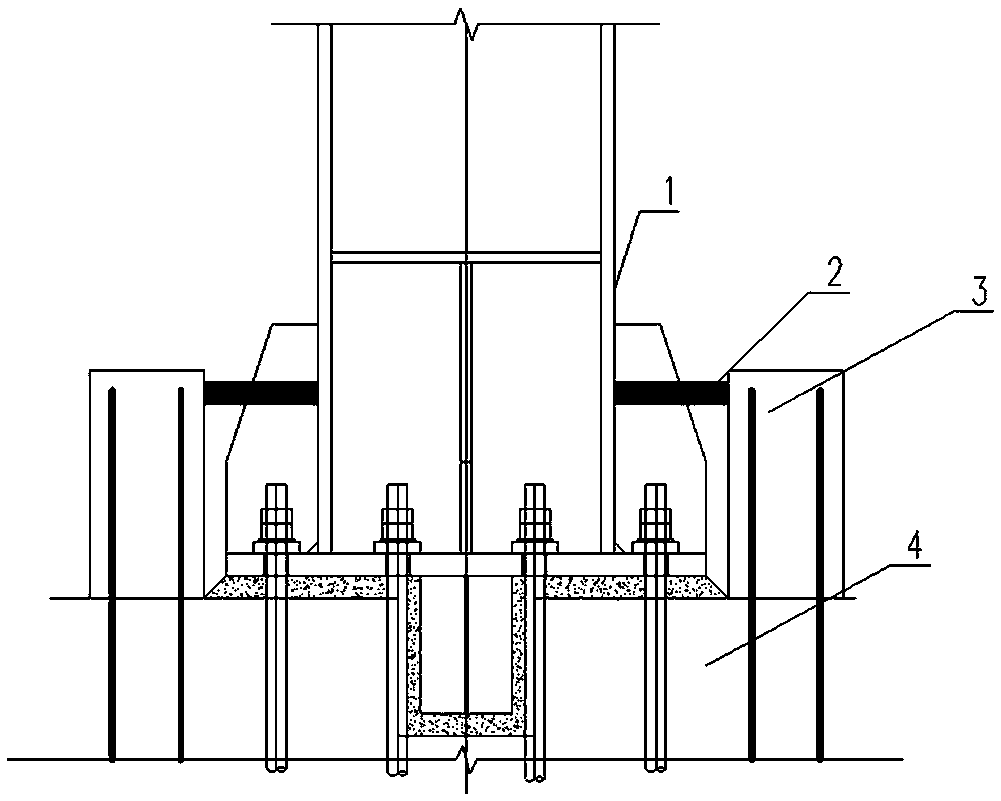

Embodiment 1

[0040] For a flue support, its natural structural frequency is 1.5Hz, the interstory height is about 3.5m, the seismic fortification intensity is 7 degrees, and its interstory displacement angle meets the specification requirements of 1 / 400>1 / 559 under the action of small earthquakes. If it is a conventional method, measures such as increasing the cross-sectional area of the structure, adjusting the overall stiffness or adding concrete slabs will be adopted. However, the present invention intends to use a damper energy dissipation device to achieve the purpose of reducing interlayer displacement. Generally, the interstory displacement when the displacement angle of the frame is 1 / 50 under a large earthquake is taken as the maximum positive and negative travel of the damper. Under the action of a small earthquake, the displacement angle of 1 / 400 can be reached. Add the damper for calculation. When the relative displacement of the damper reaches 6mm, the damping force reaches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com