Oil and water well pipe column underground cathode protecting and corrosion on-line monitoring device and method

A technology for cathodic protection and corrosion monitoring, applied in the field of downhole cathodic protection and corrosion online monitoring of oil-water well strings, can solve the problems of inability to monitor the corrosion of oil-water well strings, large floor space, and low operating efficiency, and achieves guaranteed availability. Continuous development, low power consumption, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

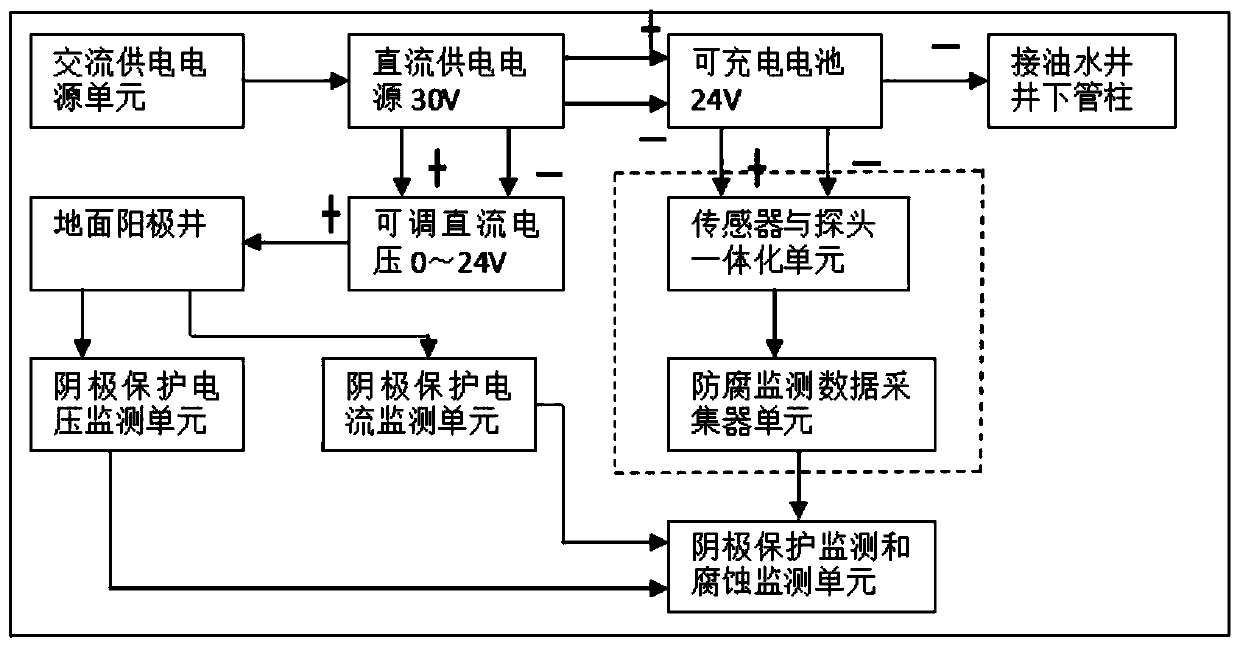

[0059] according to Figure 1-2 A downhole cathodic protection and corrosion online monitoring device for an oil-water well string is shown, including

[0060] case;

[0061] Downhole cathodic protection module, the downhole cathodic protection module is connected in the casing, and is used to provide cathodic protection current for oil and water well strings;

[0062] Downhole corrosion on-line detection module, the downhole corrosion on-line detection module is connected in the casing, and is used for on-line monitoring of pipe string corrosion rate;

[0063] The surface cathodic protection monitoring and on-line corrosion monitoring module, the ground cathodic protection monitoring and on-line corrosion monitoring module are electrically connected with the downhole cathodic protection module and the downhole corrosion online detection module.

[0064] In actual use, the downhole cathodic protection module and the downhole corrosion online detection module are connected in...

Embodiment 2

[0067] according to figure 2 A downhole cathodic protection and corrosion on-line monitoring device for oil and water well strings is different from the first embodiment in that the downhole cathodic protection module includes an AC power supply unit, a DC power supply unit, a rechargeable battery unit, Adjustable voltage unit, cathodic protection voltage monitoring unit and cathodic protection current monitoring unit; the AC power supply unit is electrically connected to the DC power supply unit, and the DC power supply unit is electrically connected to the adjustable voltage unit and the rechargeable battery unit, and the rechargeable battery unit The negative electrode is connected to the downhole pipe string of the oil-water well, and the cathodic protection voltage monitoring unit and the cathodic protection current monitoring unit are electrically connected to the ground cathodic protection monitoring and online corrosion monitoring modules.

[0068] In actual use, the ...

Embodiment 3

[0070] according to figure 2 A downhole cathodic protection and corrosion online monitoring device for oil and water well pipe strings shown differs from Embodiment 1 in that the AC power supply unit uses AC220V AC power supply, and the DC power supply unit uses The DC power supply is DC30V, the rechargeable battery unit uses a 24V rechargeable battery, and the adjustable voltage unit uses an adjustable voltage of 0-24V; the DC power supply unit uses an adjustable pulse width Modulated DC power.

[0071] In actual use, the AC power supply unit is fed with 220V AC voltage, which becomes 30V DC through the DC power supply, on the one hand, it supplies power to the rechargeable battery at 24V, and on the other hand, it supplies power to the adjustable DC device and outputs 0-24V to the The anode well is powered, and the voltage and current are monitored by the ground cathodic protection voltage monitoring unit and cathodic protection current monitoring unit, and sent to the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com