Technique for reducing excess sludge in sewage treatment plant

A technology for sewage treatment plants and excess sludge, which is applied in the oxidation treatment of sludge and wastewater treatment during processing, etc., can solve the problems of difficult removal of internal water, sludge collapse, and insignificant dehydration effect, so as to achieve low treatment costs and reduced costs. The harm of secondary pollution and the effect of reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Step 1: Test the main indicators of the sludge from the thickening tank of the urban sewage treatment plant and the primary sludge of the waste paper and papermaking sewage treatment plant.

[0045] Step 2: Take 200mL of municipal sludge and place it in a 500mL beaker, and adjust the pH value of the sludge to 7. Stir with a mechanical stirrer at 200r / min for 5min, mix papermaking sludge: municipal sludge according to the ratio range of 1:4, and obtain mixed sludge after stirring for 5min, K 2 S 2 o 8 The dosage is 30mg / g DS is added to the mixed sludge and stirred for 5min, FeSO 4 The dosage of DS is 60mg / g. Add it into the mixed sludge and continue stirring for 10min.

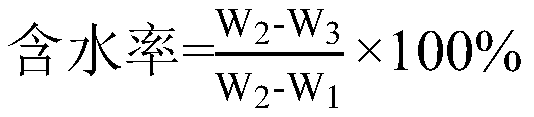

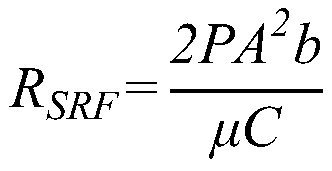

[0046] Step 3: Sludge specific resistance (SRF) Use a sludge specific resistance measuring device (KL-WBC-1 type, Wuhan Kelingao Teaching Equipment Co., Ltd.). Dry the filter paper together with the glass slide in an oven at 105°C to constant weight, and then put it in a desiccator to room temperatu...

Embodiment 2

[0050] Step 1: Test the main indicators of the sludge from the thickening tank of the urban sewage treatment plant and the primary sludge of the waste paper and papermaking sewage treatment plant.

[0051] Step 2: Take 200mL of municipal sludge and place it in a 500mL beaker, and adjust the pH value of the sludge to 7. Stir with a mechanical stirrer at 200r / min for 5min, mix papermaking sludge: municipal sludge according to the ratio range of 1:2, and obtain mixed sludge after stirring for 5min, K 2 S 2 o 8 The dosage is 30mg / g DS is added to the mixed sludge and stirred for 5min, FeSO 4 The dosage of DS is 60mg / g. Add it into the mixed sludge and continue stirring for 10min.

[0052] Step 3: Sludge specific resistance (SRF) Use a sludge specific resistance measuring device (KL-WBC-1 type, Wuhan Kelingao Teaching Equipment Co., Ltd.). Dry the filter paper together with the glass slide in an oven at 105°C to constant weight, and then put it in a desiccator to room temperatu...

Embodiment 3

[0056] Step 1: Test the main indicators of the sludge from the thickening tank of the urban sewage treatment plant and the primary sludge of the waste paper and papermaking sewage treatment plant.

[0057] Step 2: Take 200mL of municipal sludge and place it in a 500mL beaker, and adjust the pH value of the sludge to 7. Stir with a mechanical stirrer at 200r / min for 5min, mix papermaking sludge: municipal sludge according to the ratio range of 3:4, and obtain mixed sludge after stirring for 5min, K 2 S 2 o 8 The dosage is 30mg / g DS is added to the mixed sludge and stirred for 5min, FeSO 4 The dosage of DS is 60mg / g. Add it into the mixed sludge and continue stirring for 10min.

[0058] Step 3: Sludge specific resistance (SRF) Use a sludge specific resistance measuring device (KL-WBC-1 type, Wuhan Kelingao Teaching Equipment Co., Ltd.). Dry the filter paper together with the glass slide in an oven at 105°C to constant weight, and then put it in a desiccator to room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com