Life facilitating dustbin achieving solid-liquid separation

A technology of solid-liquid separation and garbage bins, which is applied in the direction of garbage cans, garbage collection, waste collection and transfer, etc., can solve the problems of inability to dispose of solid garbage, poor user experience, etc., achieve simple structure, reduce the number of garbage dumps, and use Experience the best effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

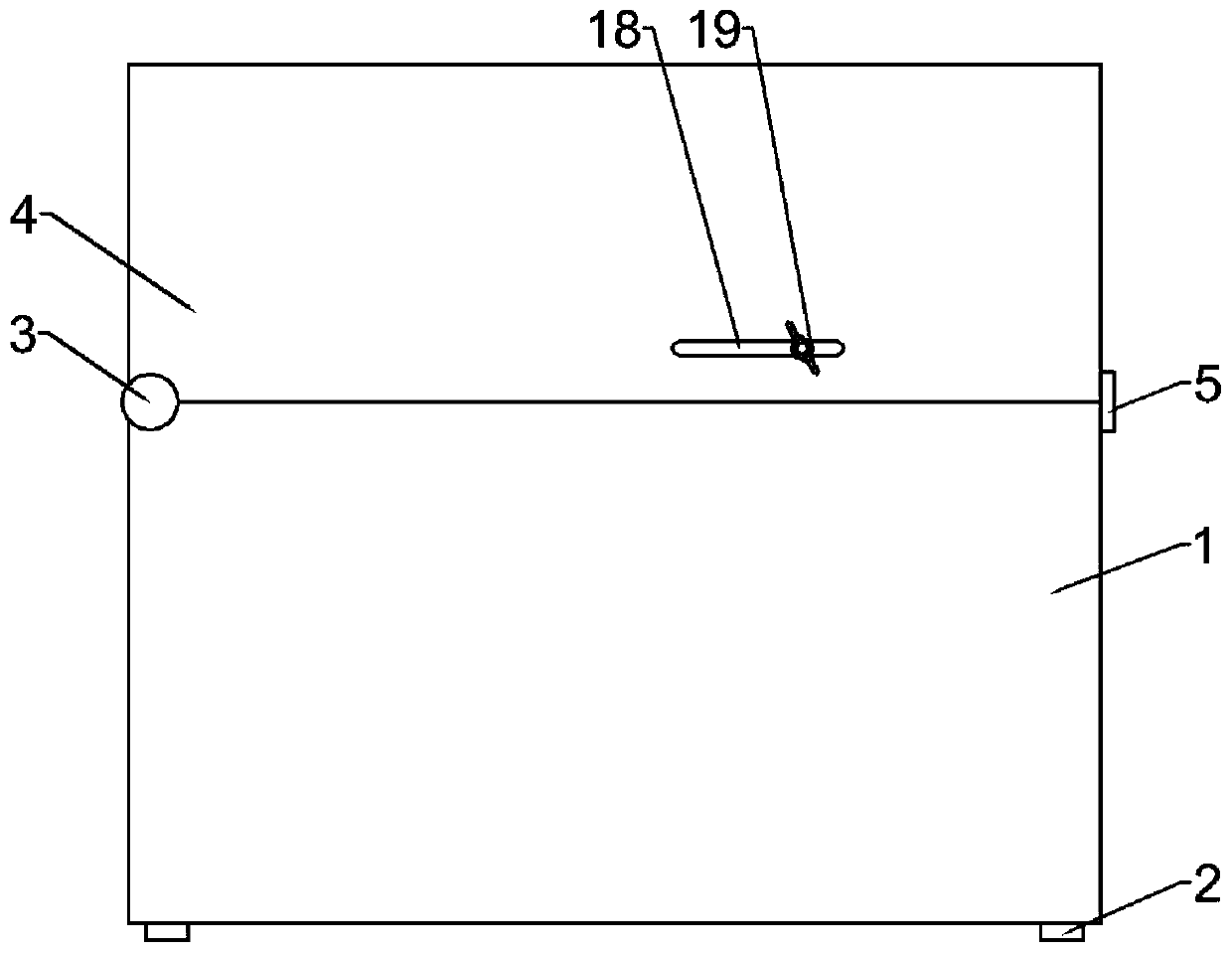

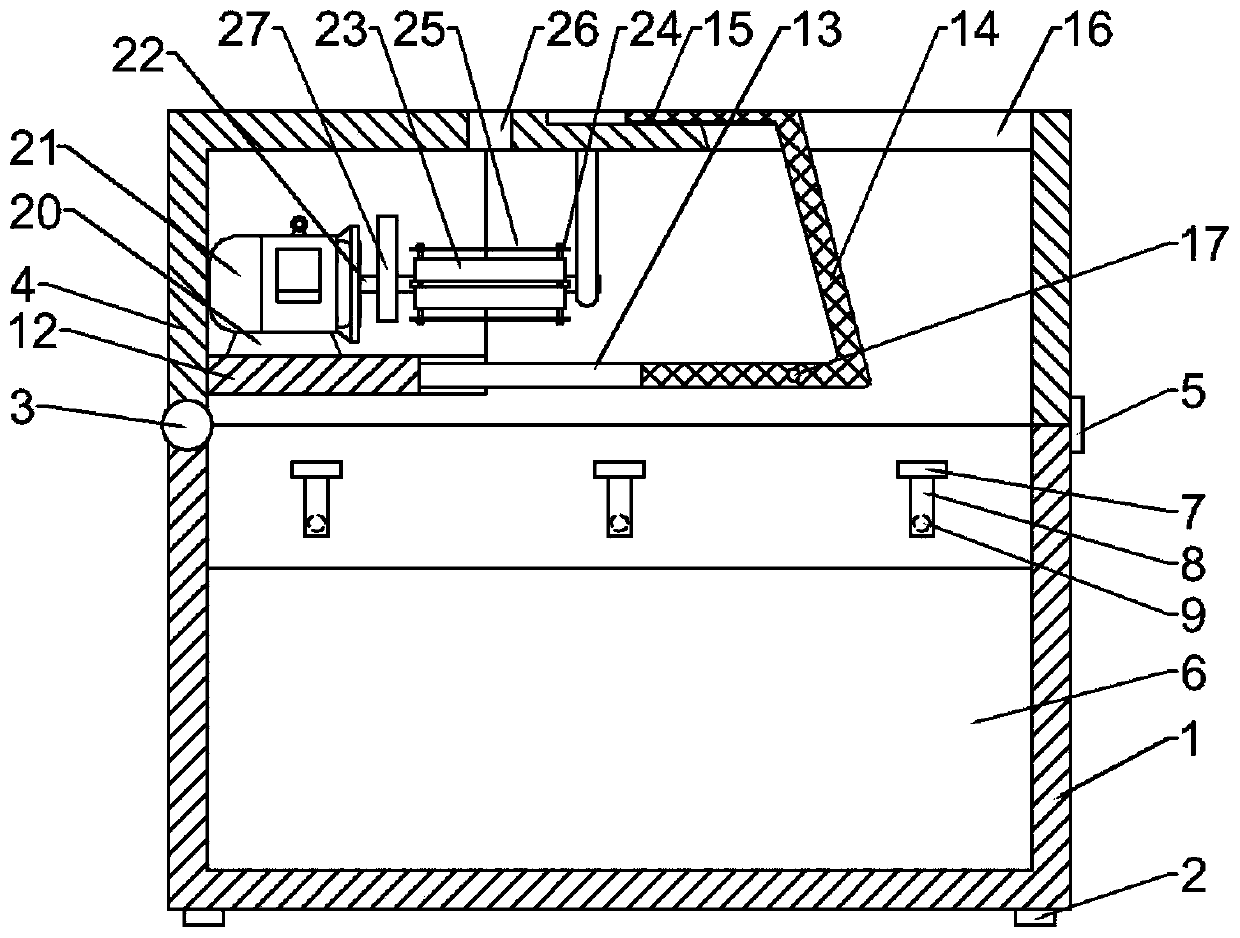

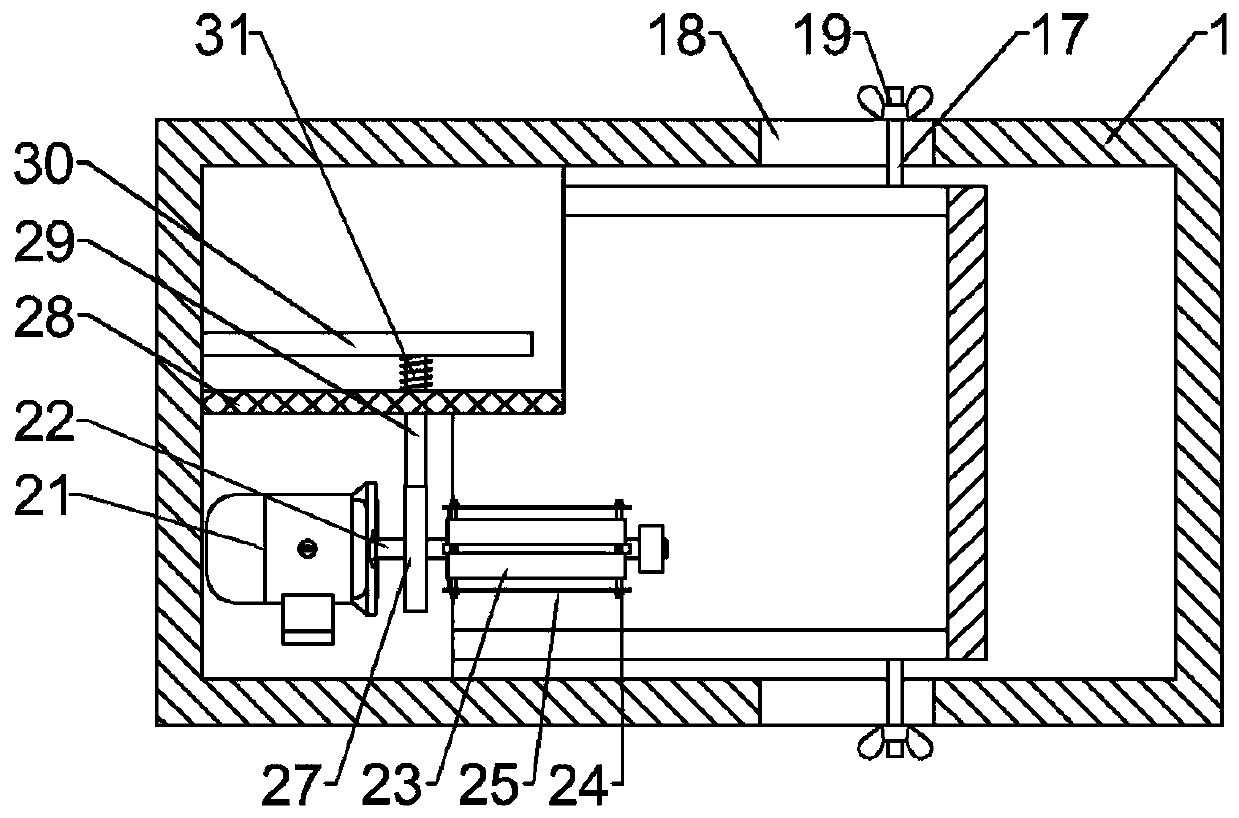

[0027] Example 1: Please refer to Figure 1-6 , a solid-liquid separation life convenience garbage bin, comprising a lower box 1, the lower box 1 is a rectangular box, the upper left of the lower box 1 is fixedly connected with a first hinge 3, and the top of the first hinge 3 is rotatably connected with an upper box Body 4, the upper box body 4 is a rectangular box body, the upper box body 4 and the lower box body 1 are connected by buckles 5, the lower box body 1 is fixedly connected with a longitudinal partition 6 inside, and the lower box body The front and rear side walls of the body 1 are fixedly connected with a number of fixing devices, the fixing device includes a second hinge 7, a swinging pressure plate 8 is fixedly connected below the second hinge 7, and a first magnet 9 is fixedly connected to the outside of the swinging pressure plate 8, and the first magnet 9 Mutual attraction with the side wall of the lower box body 1, the side wall of the lower box body 1 is p...

Embodiment 2

[0029] Embodiment 2: This embodiment is a further improvement of the previous embodiment: the upper left side of the upper box body 4 is fixedly connected with a mounting base plate 12, and the right side of the mounting base plate 12 is symmetrically slidingly connected with a horizontal connecting rod 13, and the right side of the horizontal connecting rod 13 is Fixedly connected with an inclined guide plate 14, the top of the inclined guide plate 14 runs through the blanking hole 16 provided on the right side of the upper box body 4 and is fixedly connected with a horizontal shutter 15, which is slidingly connected with the top of the upper box body 4. The inclined guide plate 14 The front and rear sides are fixedly connected with a positioning adjustment screw 17, and the front and rear side walls of the upper box body 4 are symmetrically provided with adjustment grooves 18, and the adjustment screw 17 runs through the adjustment groove 18 and is connected with a butterfly n...

Embodiment 3

[0031] Embodiment 3: This embodiment is a further improvement of the previous embodiment: a motor bracket 20 is fixedly connected to the front side above the installation base plate 12, a motor 21 is fixedly connected above the motor bracket 20, and a drive shaft is fixedly connected to the output end of the motor 21. 22. The outer side of the drive shaft 22 is fixedly connected with a rotating roller 23, and the outer side of the rotating roller 23 is fixedly connected with a crushing blade 25 through a fixedly installed knife holder 24. The bottom of the crushing blade 25 is connected with the lower box body 1, and the upper box The top of the body 4 is provided with a crushing through hole 26, and the crushing through hole 26 is located directly above the crushing blade 25;

[0032] There are two types of garbage in the process of sorting and placing garbage. One is strip-shaped hard objects such as bamboo sticks that are very easy to pierce garbage bags. This kind of garbag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com