Treatment method and device of diketene process waste gas

The technology of diketene and treatment device is applied in the field of treatment of waste gas of diketene process, which can solve problems such as polluting the atmospheric environment, and achieve the effects of improving safety, ensuring cleanliness and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

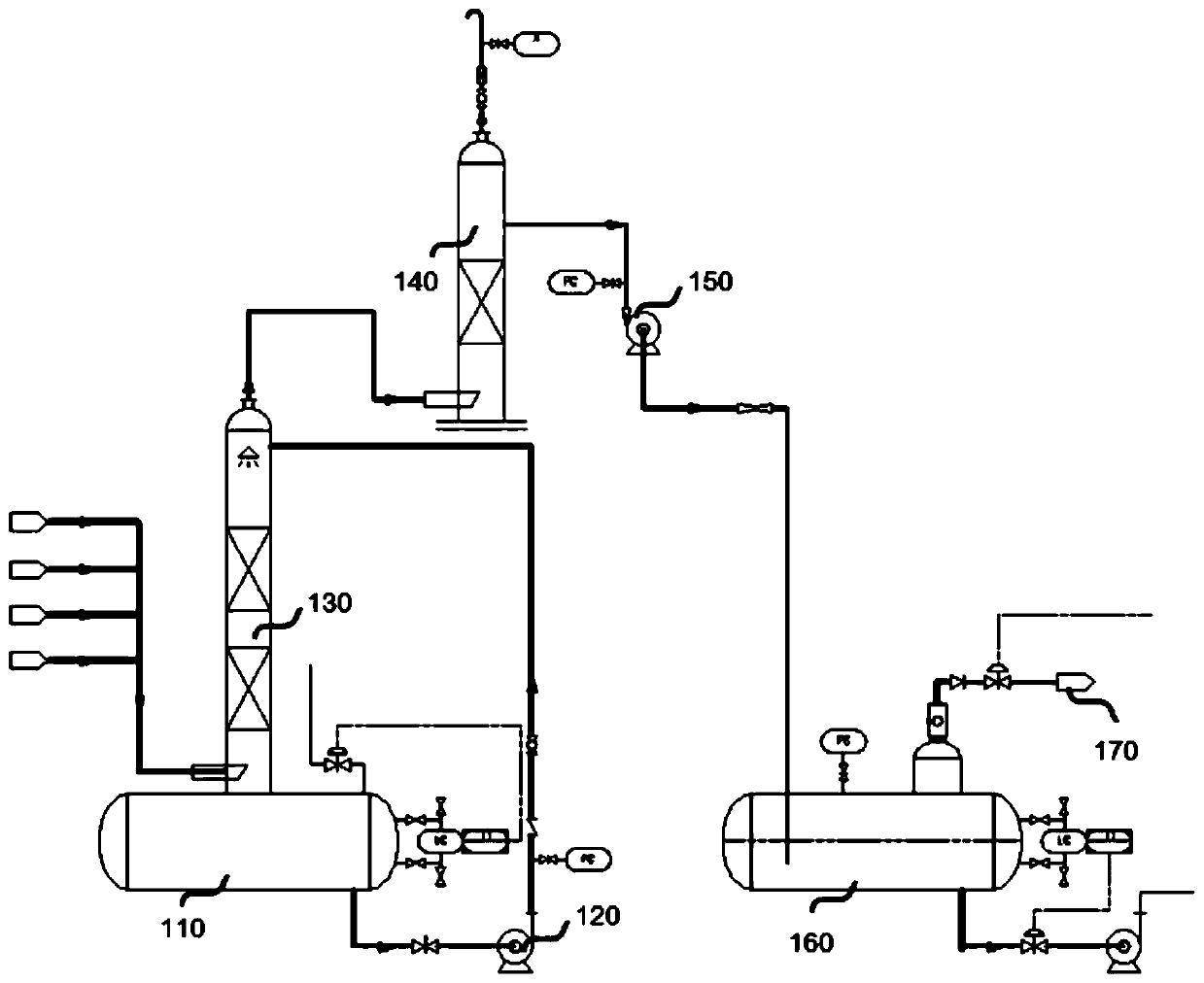

[0019] Embodiment 1 proposes a treatment device for diketene process waste gas, including: tail gas absorption circulation tank 110, circulating water pump 120, tail gas absorption tower 130, activated carbon adsorption tower 140, induced draft fan 150, tail gas water sealing tank 160 and cracking furnace 170 . Wherein, the tail gas absorption circulation tank 110 communicates with the circulating water pump 120 and the tail gas absorption tower 130 respectively, the tail gas absorption tower 130 communicates with the activated carbon adsorption tower 140, and the activated carbon adsorption tower 140 communicates with the induction The fan 150 is in communication, the induced draft fan 150 is in communication with the tail gas water sealing tank 160 , and the tail gas water sealing tank 160 is in communication with the cracking furnace 170 .

[0020] Advantageously, in the waste gas treatment device of the diketene process, the filler in the tail gas absorption tower adopts s...

Embodiment 2

[0022] Example 2 proposes a method for using the device to treat diketene process waste gas.

[0023] The method for utilizing said device to process diketene process waste gas may further comprise the steps:

[0024] S101: first pass the waste gas from the diketene process into the tail gas absorption circulation tank, and after the acid anhydride, diketene and its high polymer are separated by the oil-gas separator, the ketene gas is removed through the double-stage oil ring pump to absorb the process, and finally the gas containing The tail gas of acetone and acetic acid gas is passed into the tail gas absorption tower.

[0025] S102: Circulate the tail gas in the tail gas absorption tower through the circulating water pump, absorb the organic medium dissolved in water, pass the more flammable non-condensable gas tail gas into the activated carbon adsorption tower after absorption treatment, and absorb the tail gas Oil-containing colloids, and then the tail gas is drawn ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com