Multi-channel small-diameter digital real-time imaging detection device

A real-time imaging and detection device technology, which is applied in the fields of nuclear reactor monitoring, reactors, nuclear power generation, etc., can solve the problems of inability to guarantee the rotation accuracy, affecting the rhythm requirements, and low work efficiency, so as to improve the detection production efficiency, widen the detection range, reduce the The effect of small protection against hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

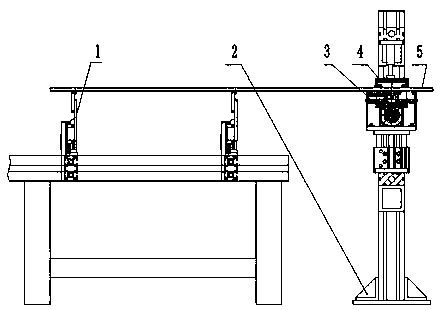

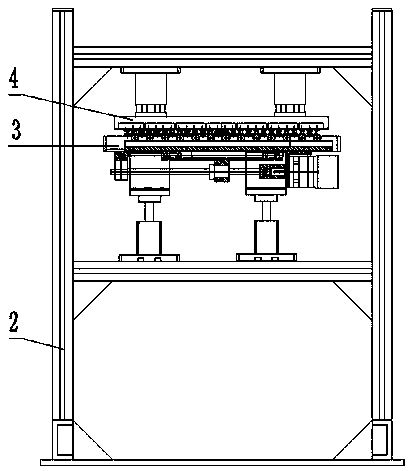

[0026] Such as Figure 1-Figure 10 The multi-channel small-diameter digital real-time imaging detection device shown includes a driven jacking roller 1, a fixed frame 2, a driving roller set 3, and a driven pressure roller set 4, wherein the driven jacking roller 1 is installed on the conveying line , arranged equidistantly with the driving roller group 3, the driving roller group 3 is installed on the jacking cylinder 205 of the fixed frame 2, and the driven pressure roller group 4 is installed on the pressing piece cylinder 206 of the fixed frame 2. The small-diameter rod (pipe) part 5 is located on the driving roller group 3, and the driven roller group 4 is below.

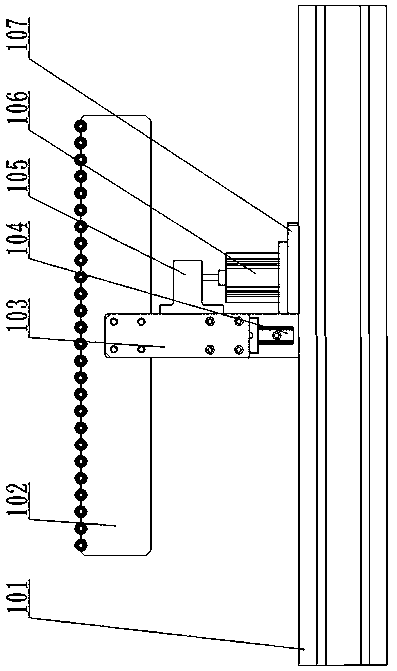

[0027] Driven jacking roller 1 comprises: fixed profile 101, driven wheel fixed seat plate 102, slide block fixed plate 103, linear guide rail 104, cylinder connecting plate 105, jacking cylinder 106, cylinder fixed plate 107, driven wheel shaft one 108, Spacer 109, driven wheel one 110, snap spring one 111; f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com