Full-automatic X-ray real-time imaging detection device for cable

A real-time imaging and detection device technology, which is applied in the direction of material analysis using radiation, can solve problems such as low work efficiency, inability to be comprehensive, and slow detection progress, so as to broaden the detection range, improve detection production efficiency, and reduce protection hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

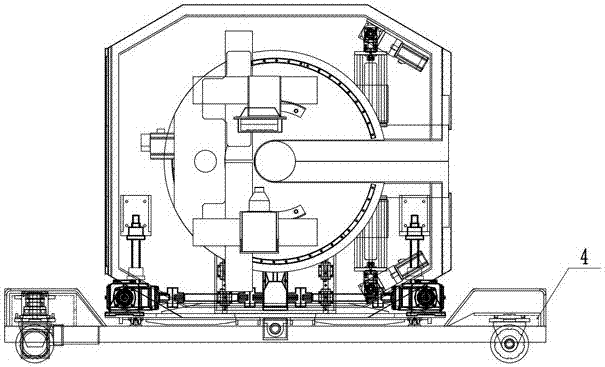

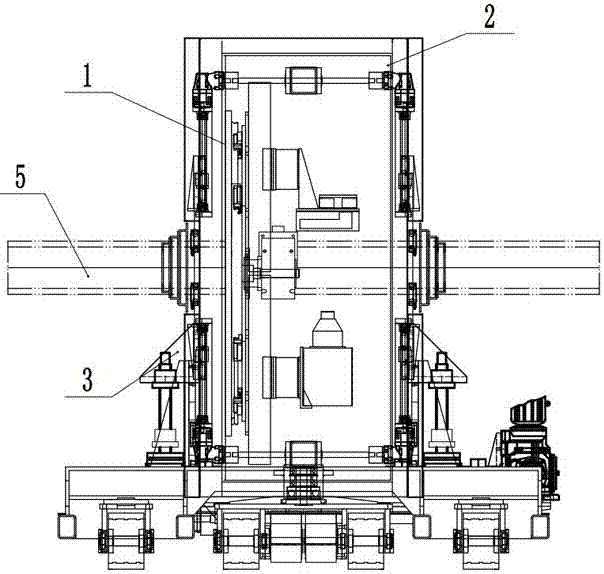

[0020] like Figure 1-Figure 12 A fully automatic X-ray real-time imaging detection device for cables is shown, including: an arc arm 1, a lead room 2, a lead room support mechanism 3, a transport vehicle 4, and a cable 5, wherein the arc arm 1 is installed in the lead room 2 arm, the lead house 2 is installed on the lead house support mechanism 3, the lead house support mechanism 3 is then fixed on the transport cart 4, and the detected cable 5 is located at the center of the device.

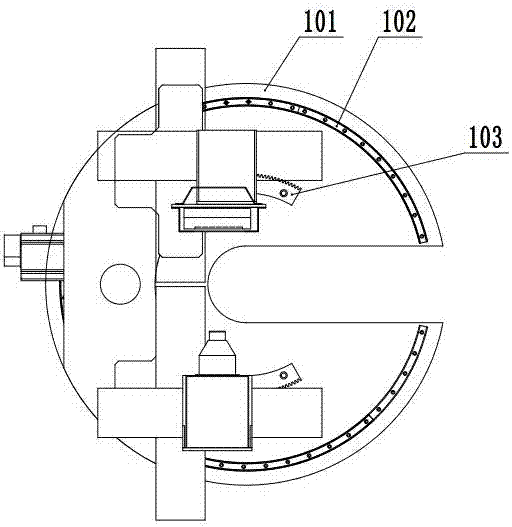

[0021] The arc arm 1 includes: arc arm bottom fixing plate 101, arc guide rail 102, arc rack 103, arc arm rotating plate 104, arc arm module support plate 105, translation servo motor 106, linear module 107, arc arm module conversion plate 108, imaging plate parts 109, imaging plate 110, ray machine 111, ray machine fixed plate 112, rotary reducer baffle plate 113, rotary reducer backing plate 114, rotary reducer shaft 115, A rotary gear 116 , a rotary reducer 117 , and a rotary servo motor 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com