Magnetic valve and vehicle cooling system utilizing magnetic valve

A cooling system, magnetic technology, applied in the layout of the cooling combination of the power unit, vehicle components, valve operation/release devices, etc., can solve the problems of lip seal leakage, increased integration difficulty, and mechanical parts stuck. , to achieve easy integration, reduce leakage risk, and reduce HC&CO emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

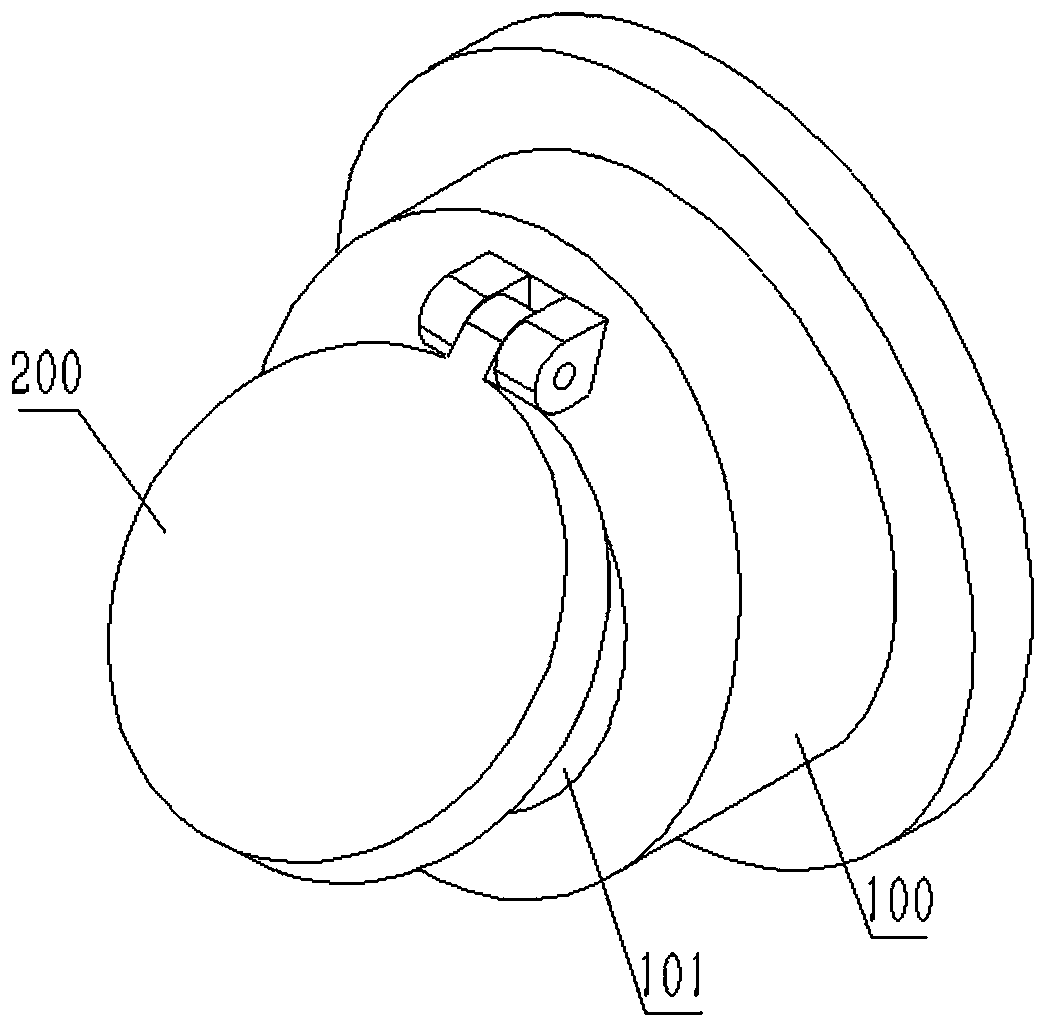

[0023] Please see attached figure 1 As shown, a magnetic valve includes a valve body 100 and a valve cover 200; the middle part of the valve body 100 is provided with a through passage 101, the valve cover 200 and the valve body 100 are hinged, and when the two are in contact, the valve The cover 200 closes the through passage 101; the contact between the valve body 100 and the valve cover 200 is polished to form a sealing surface.

[0024] The valve body 100 is made of temperature-sensitive ferrite iron, and the valve cover 200 is made of permanent magnet.

[0025] The valve body 100 is made of permanent magnets, and the valve cover 200 is made of temperature-sensitive ferrite iron.

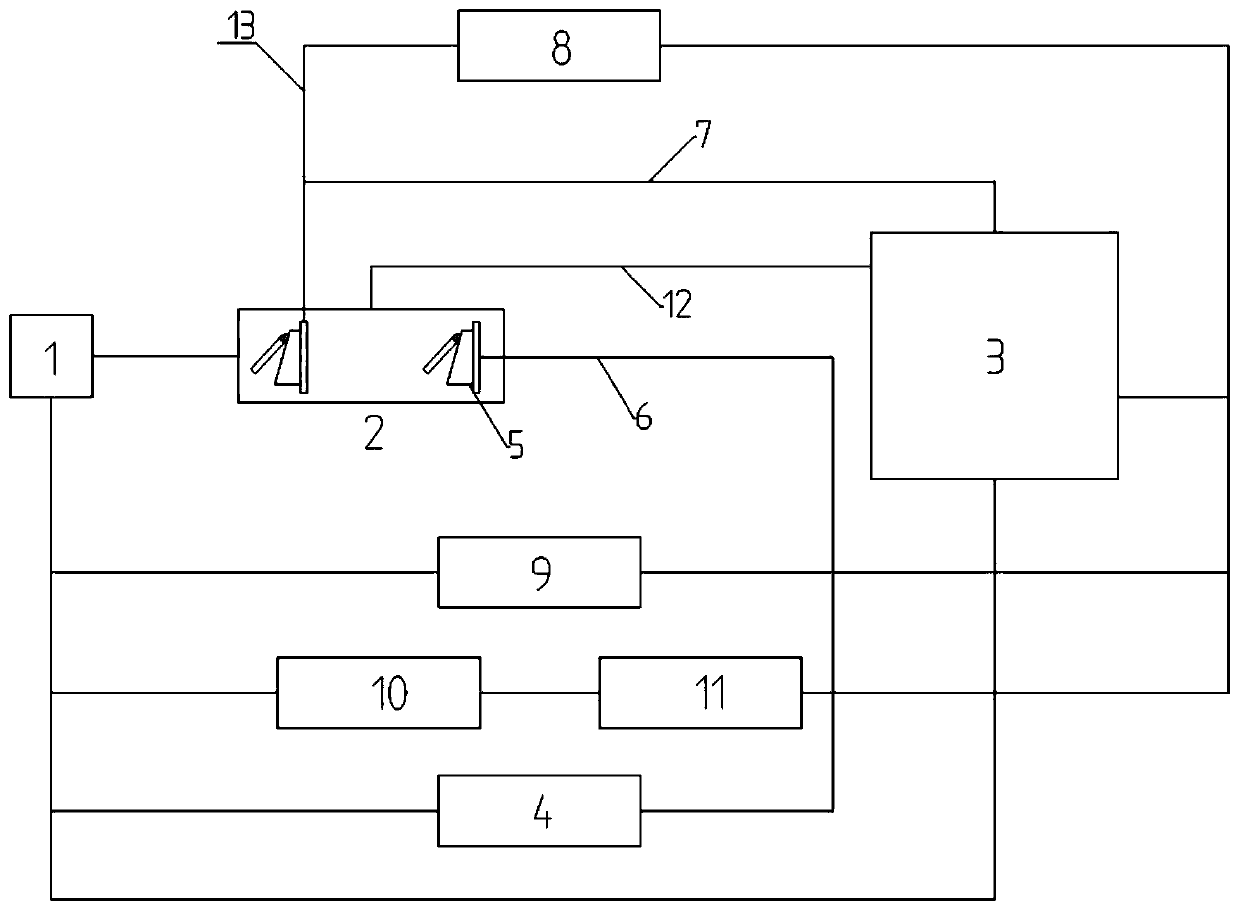

[0026] Please see attached figure 2 As shown, the present invention also discloses a vehicle cooling system using the magnetic valve, including an electronic water pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com