Method for making small temperature swing adsorption curve for coalbed methane drainage

A technology of temperature swing adsorption and manufacturing method, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of misjudgment and error in the evaluation of commercial exploitation potential of coalbed methane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

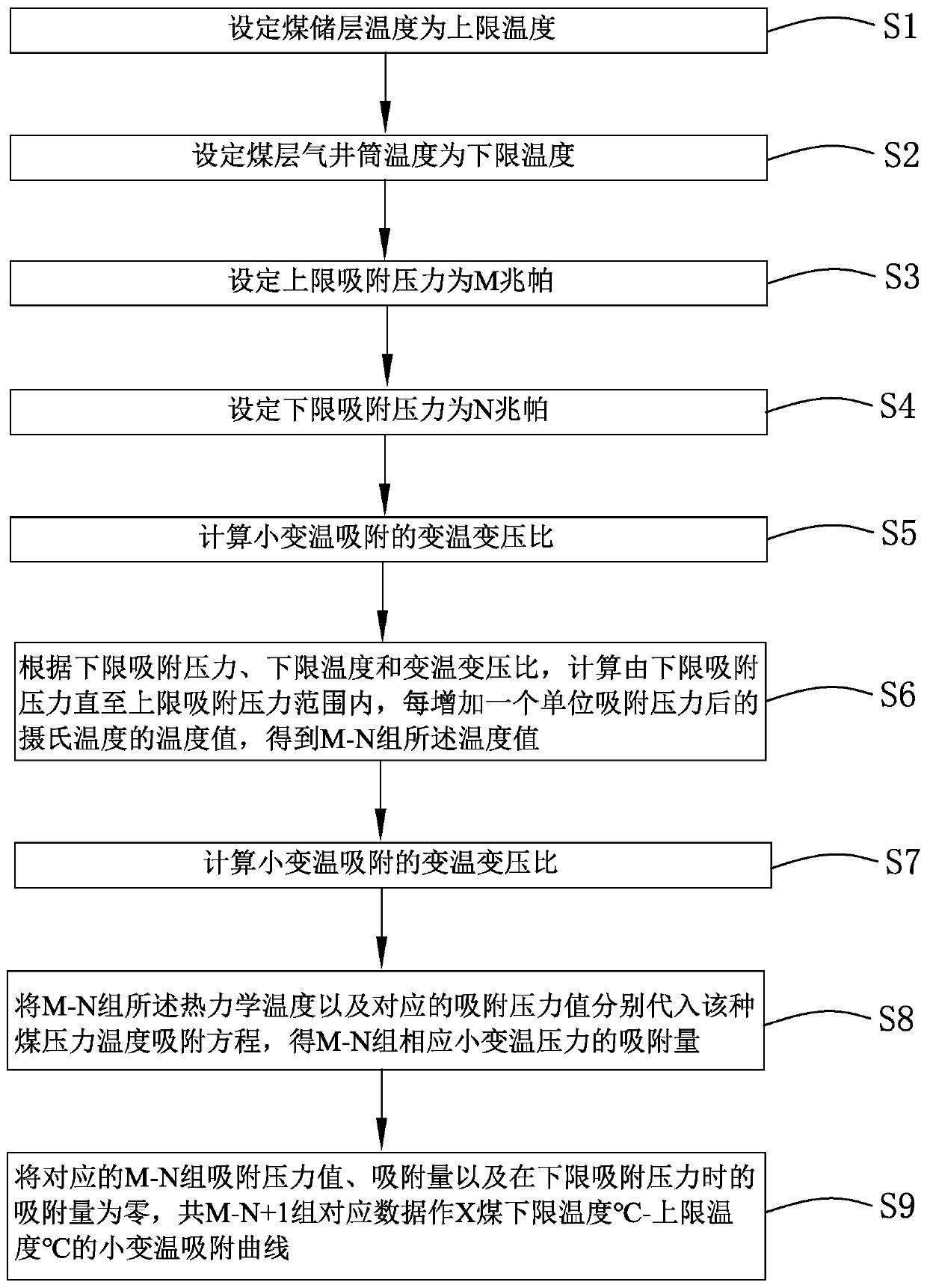

[0031] see Figure 1-2 , the following will be explained with specific examples:

[0032] Taking Shanxi Nanyu Mine Fatty Coal (NY) as an example: Using the existing pressure-temperature adsorption equation, the characteristic The geometric constant A of fat coal, the adsorption flow coefficient B representing the adsorption surface of fat coal, the parameter to measure the influence of temperature on the adsorption amount of fat coal, and the parameter to measure the influence of pressure on the adsorption amount of fat coal are shown in Table 1-Table 2:

[0033] Table 1 Basic properties of fat coal and coal isothermal adsorption results under equilibrium water conditions

[0034]

[0035] Table 2 The basic properties of fat coal and the parameters of the pressure-temperature adsorption equation in the range of 30°C-50°C

[0036] serial number sampling location coal rank A B NY Shanxi Nanyu Mine Fat coal 0.168 0.002031 953.3 0.5342

...

Embodiment 2

[0061] Taking the fertilizer coal (NY) of Nanyu Mine in Shanxi as an example, it is operated in the coal field of Nanyu Mine of Shanxi. Although it is known that coal is fat coal and has a 30°C isothermal adsorption Rankine volume V L and Langley pressure P L and 50°C isothermally adsorbed Rankine volume V l and Langley pressure P l , its basic properties and isothermal adsorption are listed in Table 1 in the above-mentioned embodiment one. However, the temperature of the coal reservoir measured on site is indeed 40°C, while the temperature of the coalbed methane wellbore is 37°C. Calculate and make 37 ℃-40 ℃ small temperature swing adsorption curve by the method step of the present invention, this method comprises the following steps:

[0062] Step S1, setting the temperature of the coal reservoir as the upper limit temperature.

[0063] According to the actual situation, since the temperature of the coal reservoir measured on site is 40°C, that is, the upper limit tempe...

Embodiment 3

[0083] Taking lean coal (XS) of Xiangshan Mine in Shaanxi as an example: using the existing pressure-temperature adsorption equation, the characteristic lean coal The geometric constant A of the , the adsorption flow coefficient B representing the adsorption surface of lean coal, the parameter to measure the influence of temperature on the adsorption capacity of lean coal, and the parameter to measure the influence of pressure on the adsorption capacity of lean coal, as shown in Table 3-Table 4:

[0084] Table 3 Basic properties of lean coal and coal isothermal adsorption results under equilibrium water conditions

[0085]

[0086] Table 4 The basic properties of lean coal and the parameters of the pressure-temperature adsorption equation in the range of 30°C-50°C

[0087] serial number sampling location coal rank A B XS Shaanxi Xiangshan Mine lean coal 0.168 0.002059 1149.5 0.4644

[0088] Table 3 lists the basic properties of lean coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com