An automatic towel continuous seaming device and its seaming method

A towel and seaming technology, applied in textile and papermaking, sewing equipment, cloth pressing mechanism, etc., can solve the problems of continuous seaming and low degree of automation, so as to improve seaming quality and production efficiency, and improve seaming efficiency. , The effect of improving the efficiency of automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

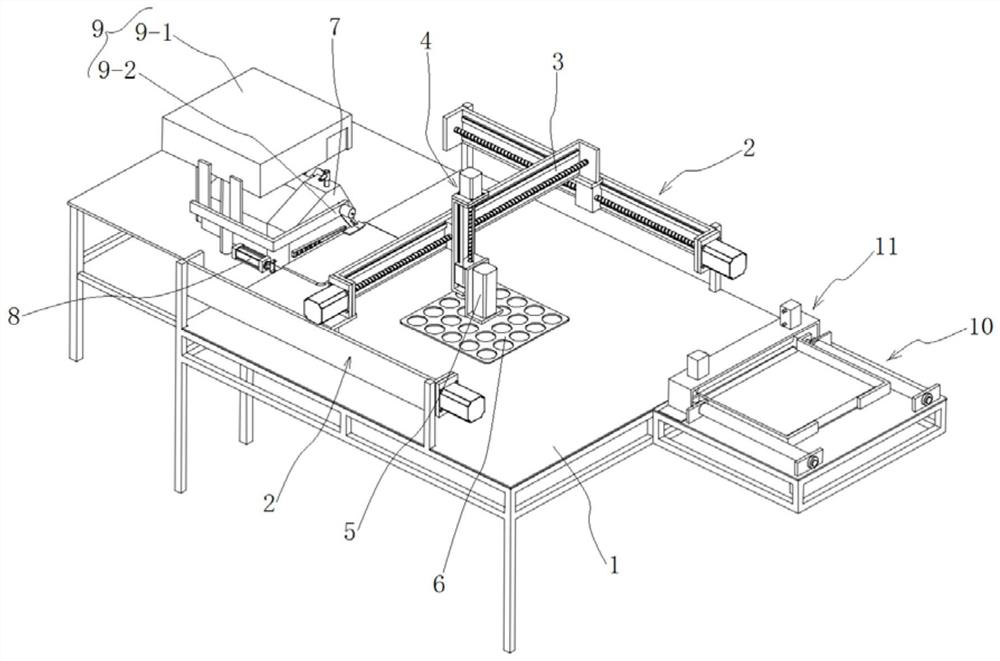

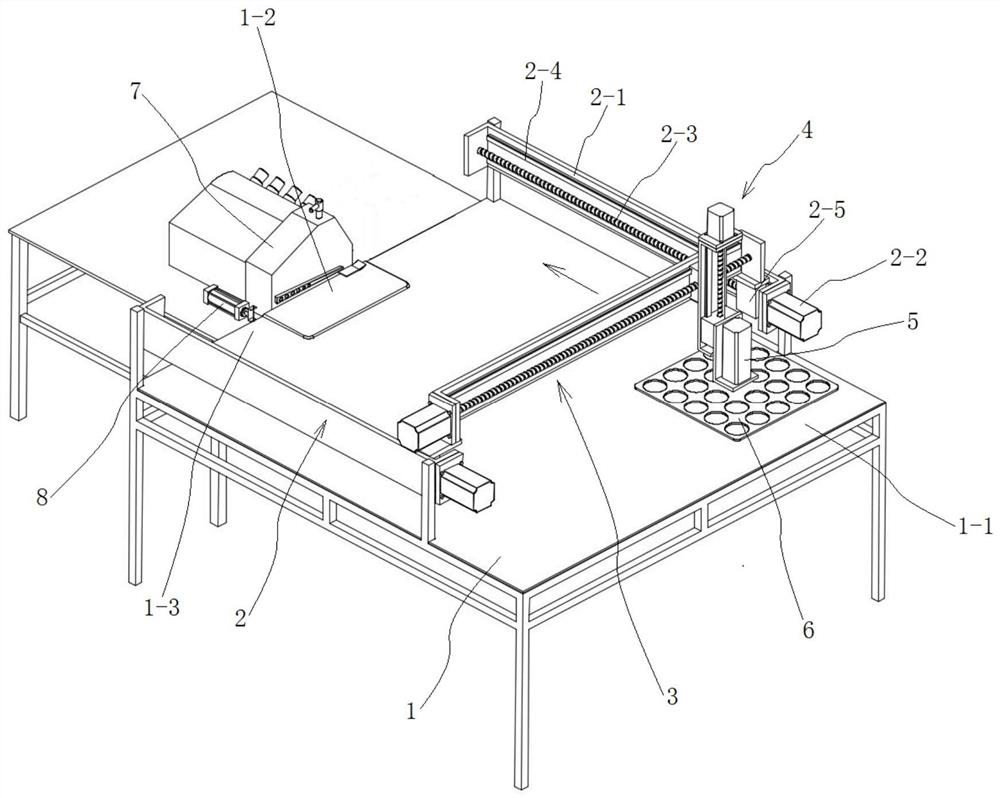

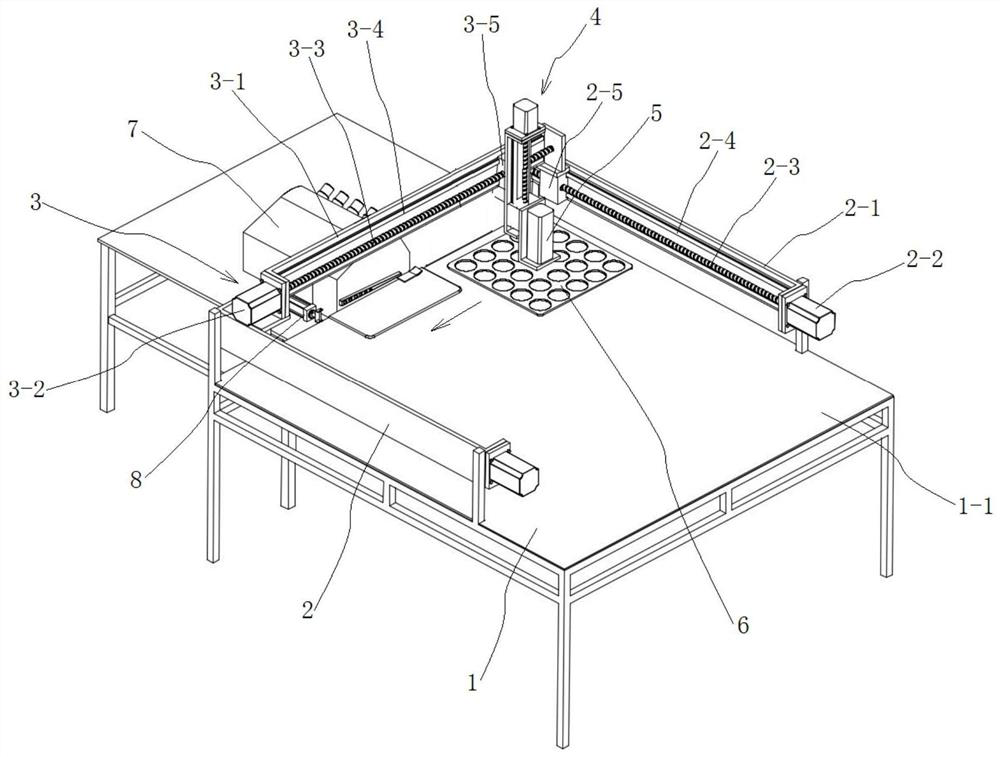

[0055] Such as Figure 1 to Figure 9 As shown, a kind of automatic towel continuous seaming device of the present embodiment comprises a workbench 1, a towel clamping and moving mechanism arranged on the workbench 1, a seaming machine head 7 for seaming the edges of towels, and a In order to control the controller of the towel clamping and moving mechanism and the head 7 of the overlock machine, there is a loading station 1-1 on the workbench 1 for receiving the towel fabric delivered by the conveying mechanism and for installing the overlock machine head 7, the seaming station 1-2, the bottom of the towel clamping mobile mechanism is provided with a pressure plate 6 parallel to the table surface of the workbench 1, and the towel clamping mobile mechanism has the ability to drive the pressure plate 6 to move up and down, rotate, and move horizontally and horizontally. The motion execution unit of movement and longitudinal movement, the controller is electrically connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com