A shield machine hob automatic replacement device

An automatic replacement, shield machine technology, applied in the direction of manufacturing tools, mining equipment, tunnels, etc., can solve the problems of high work intensity, low safety factor, manual operation, etc., to reduce labor intensity, easy operation, simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

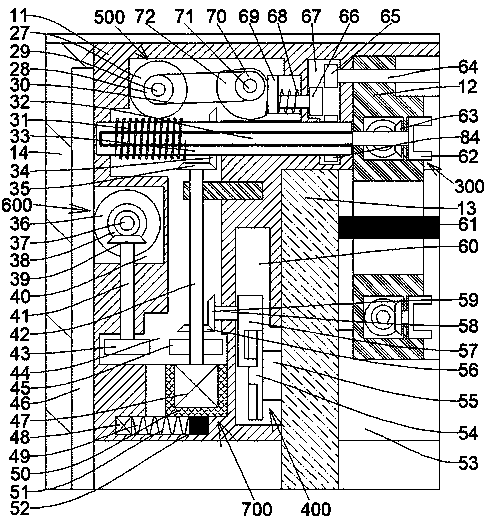

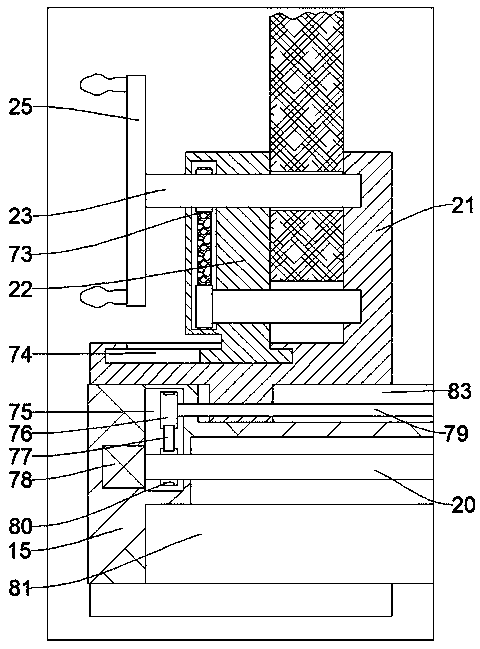

[0019] The present invention will be described in detail below in conjunction with the above-mentioned diagrams, wherein, for the convenience of description, the orientations mentioned below are stipulated as follows: figure 1 The up and down directions of the projection relationship are the same.

[0020] The present invention relates to an automatic hob replacement device for a shield machine, which is mainly used for replacing worn hobs on the cutter head of a shield machine underground. The present invention will be further described below in conjunction with the drawings of the present invention:

[0021] A shield machine hob automatic replacement device according to the present invention comprises a main board 15, a sliding groove 83 is arranged in the main board 15, a slidable fixed plate 21 is arranged in the sliding groove 83, the fixed The fixed plate 21 is provided with a fixing device 100, the bottom wall of the sliding groove 83 is provided with a folding groove 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com