Core expansion fixture with spacer and method of use thereof

A technology of gasket and core expansion, applied in the field of core expansion fixtures with gaskets, can solve the problems of low coaxiality of the shell of aviation bombs, inability to meet processing requirements, difficult to ensure high coaxiality, etc. Product qualification rate and production efficiency, high coaxiality, and the effect of reducing core pressure requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

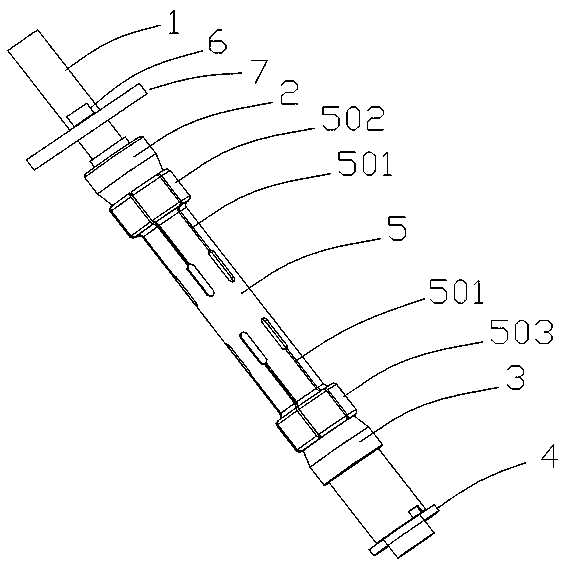

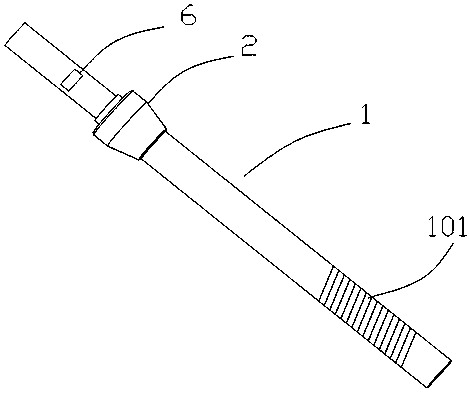

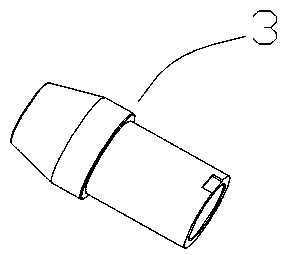

[0045] Such as Figure 1-7 As shown, a core expansion fixture with a gasket is used for core expansion clamping of workpieces with ravines in the inner cavity, including: a concentric shaft 1 for support, and a limiting taper end sleeved on one side of the concentric shaft 2. The movable taper end 3 and the gasket set set on the other side of the concentric shaft; the limit taper end 2 set on one side of the concentric shaft, and the movable taper end 3 set on the other side of the concentric shaft , and the gasket set sleeved on both sides of the concentric shaft;

[0046] The limiting taper end is installed and fixed with the concentric shaft, and the movable taper end can slide along the concentric shaft. An external thread 101 is provided on the side of the concentric shaft near the movable taper end. The outer thread 101 on the concentric shaft The threaded section is provided with a lock nut 4; the lock nut is used to push the movable taper end close to the limit taper ...

Embodiment 2

[0059] During the clamping operation, first select the first gasket set and the second gasket set of the appropriate type, place the first gasket set on the inner wall of the workpiece at the position corresponding to the first expansion core flap set, and place the second gasket set The group is placed on the inner wall of the workpiece at a position corresponding to the second expansion core valve group; then, align the inner cavity of the workpiece with the concentric shaft, and feed it in from the side of the movable taper end until the workpiece is against the positioning plate, and then tighten and lock nut, so that the near limit taper end side and the near movable taper end end side of the taper expansion core successively complete the expansion core fixing of the inner cavity of the workpiece.

[0060] When placing the second gasket group, the position of the second arc-shaped gaskets is properly adjusted so that the protrusion 903 on each second arc-shaped gasket 902 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com