Dynamic testing platform for leg joints of foot-type bionic robot

A bionic robot and dynamic testing technology, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of lack of overall joint application effect testing, complicated process, high cost, etc., and achieve simple structure, time and cost saving, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] This embodiment is a dynamic test platform for leg joints of a footed bionic robot.

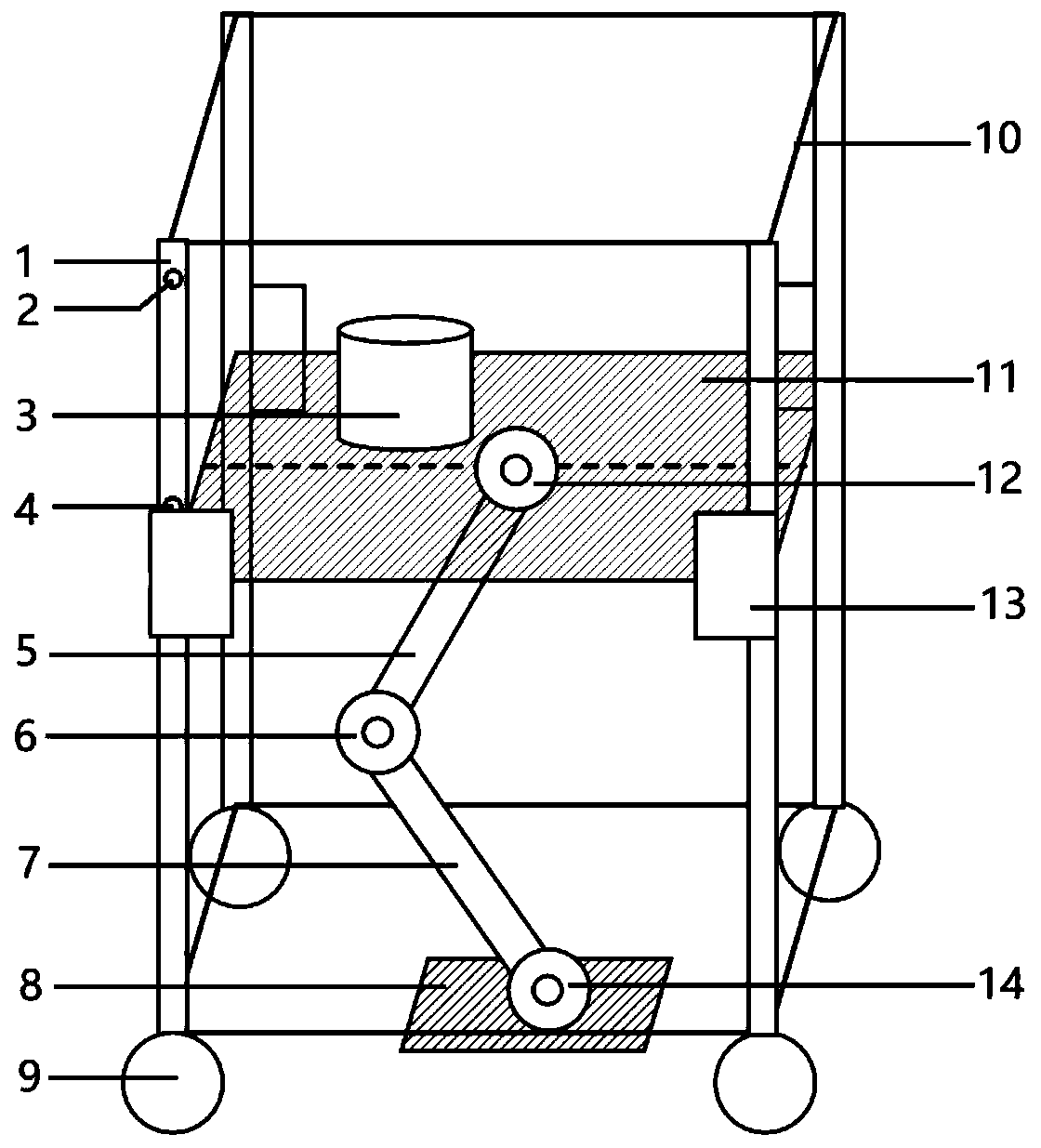

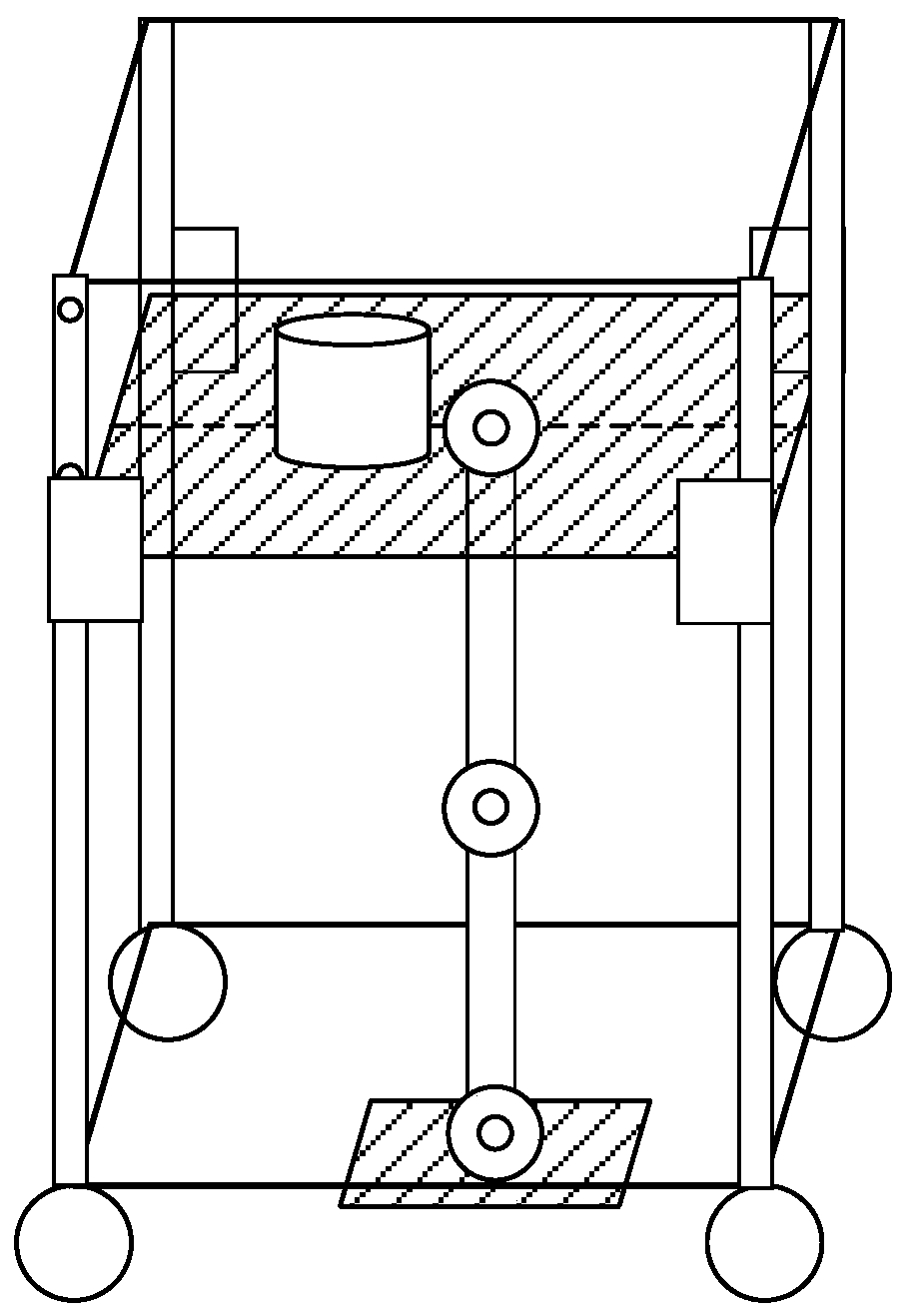

[0020] see figure 1 and figure 2 , the foot joint bionic robot leg joint dynamic test platform of this embodiment is made up of platform support, slide rail, simulation plate, position sensor, counterweight and tested robot joint; Wherein, platform support comprises two square frames 10, four Slide rail 1, four sliders 13 and four universal wheels 9, two square frames 10 are respectively located at the upper end and the lower end of vertical slide rail 1, and play the role of lateral support. The sliders 13 are respectively connected with the vertical slide rails, and can move up and down along the slide rails 1. The sliders 13 have a locking function;

[0021] The simulation panel includes an upper simulation panel 11, a lower simulation panel 8, a hip joint electric drive module 12 and an ankle joint electric drive module 14; the upper simulation panel 11 simulates the upper part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com