Composite yarn with reverse double-layer wrap structure and negative Poisson's ratio, four-passage hollow spindle spinning apparatus thereof, and control method of four-passage hollow spindle spinning apparatus

A negative Poisson's ratio, hollow spindle technology, applied in the field of spinning, can solve problems such as inability to spin yarn, and achieve the effect of achieving designability and ensuring effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

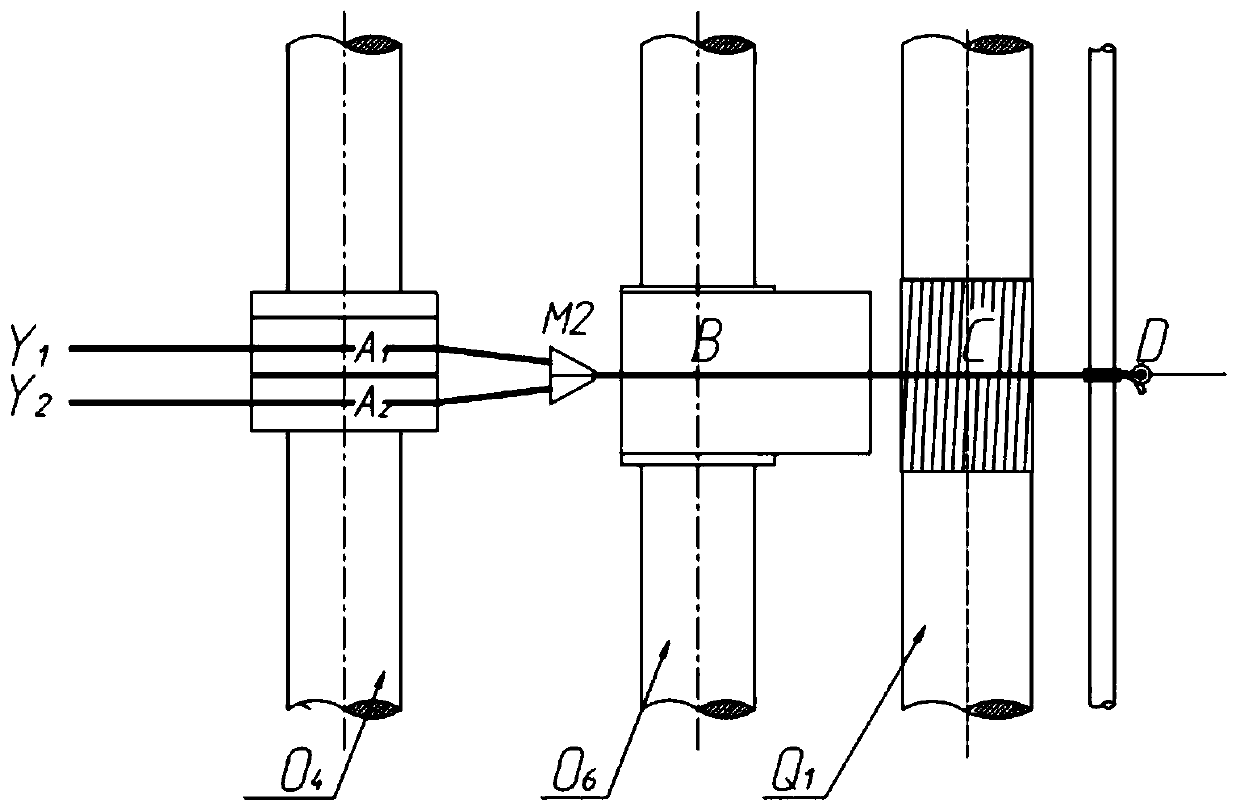

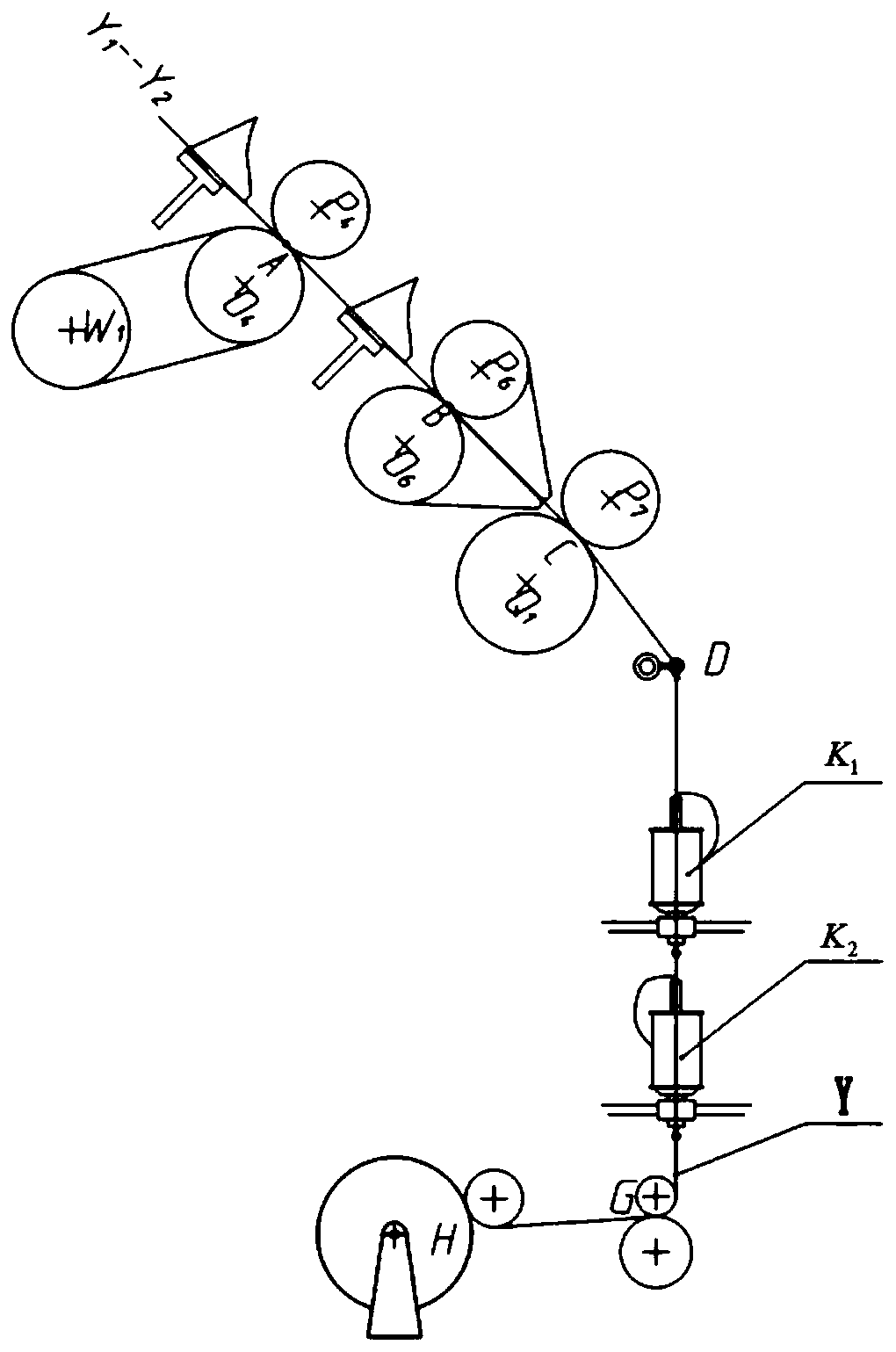

[0062] Embodiment 1, two bundles of high-performance filament fibers are selected as the wrapping filament 1 and the wrapping filament 2 in the wrapping component of the double-wrapped composite yarn, and the total proportion of the two is less than 25%; the flexible carbon fiber staple fibers are selected The strip component is used as the core component of the double-wrapping composite yarn and accounts for more than 75%.

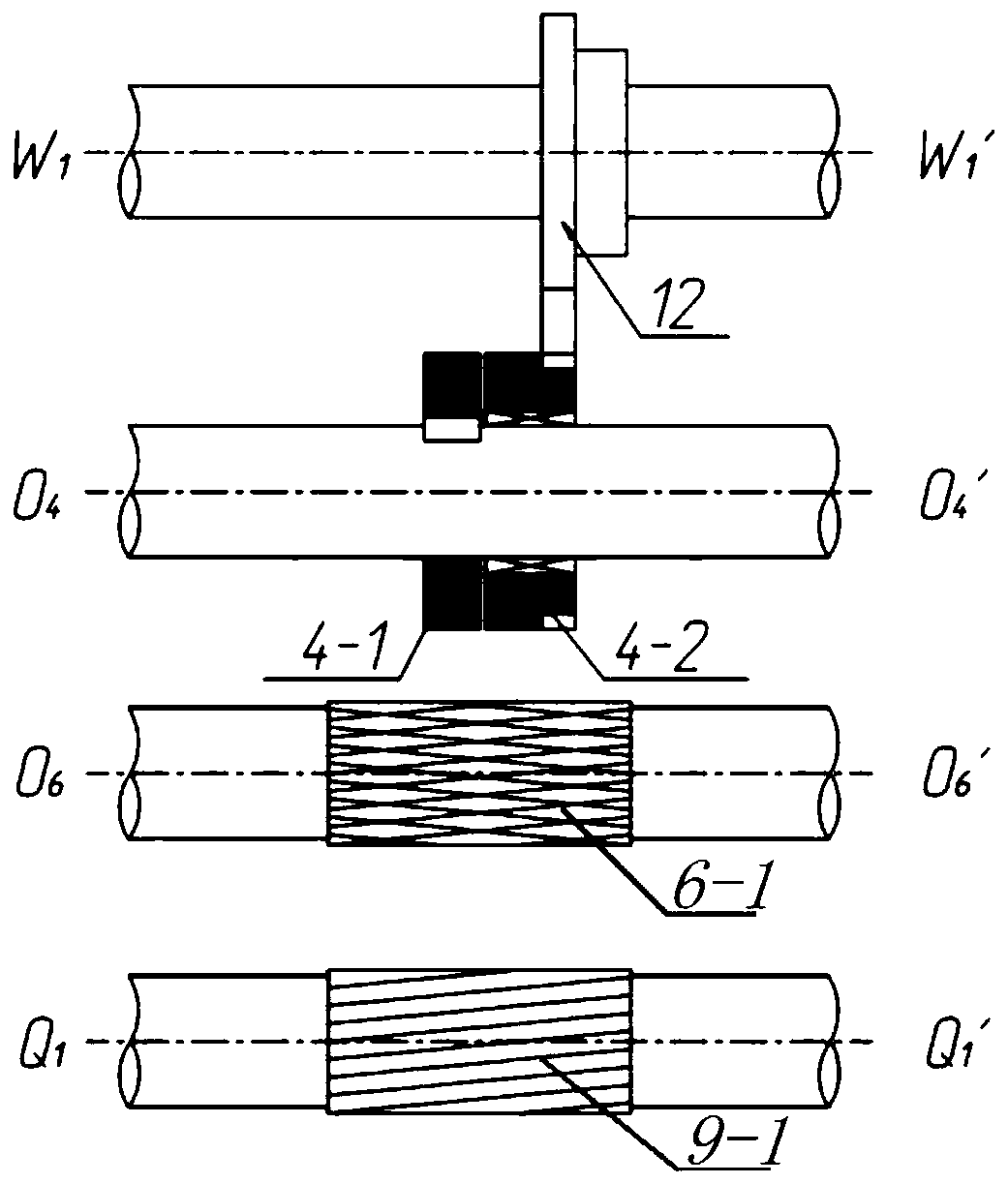

[0063] Under low tension conditions, the carbon fiber staple fiber components are linear and constitute the core yarn of the composite yarn. A bundle of filament fiber components is used as the first layer of wrapping yarn to wrap the core yarn in a helical shape. In the first layer of wrapping, another bundle of filament fiber components is used as the second layer of wrapping yarn, and the combined structure of the core yarn and the first layer of wrapping yarn is wrapped in a spiral shape for the second layer, and the first layer of wrapping The windin...

Embodiment 2

[0066] In the second embodiment, the negative Poisson's ratio of the composite yarn is due to the change of the transverse dimension of the yarn due to the phase transition of the yarn structure. Let the diameter of the core yarn be D, and the diameter of the wrapping yarn 1 be d 1 , the diameter of wrapping yarn 2 is d 2 , take d=(d 1 +d 2 ) / 2. The apparent diameter of the composite yarn under low tension conditions is: (2*d+D), and the apparent diameter of the composite yarn under high tension conditions is: (2*D+d). Then the composite yarn diameter change rate ε=-(D-d) / (D+2d). In general, the negative Poisson's ratio coefficient of the yarn is positively correlated with the diameter change rate ε. If increase the difference value (D-d) of core component and wrapping component diameter, then negative Poisson's ratio coefficient is big, if reduce the difference value (D-d) of the first component yarn and the second component yarn diameter, Then the negative Poisson's ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com