Magnetic drive type tapered hole inner surface strengthening equipment

A magnetic drive and inner surface technology, applied in the field of surface treatment of parts, can solve the problems of uneven distribution of strengthening residual stress and inability to process tapered holes, etc., to achieve uniform distribution of residual stress, convenient operation and good strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

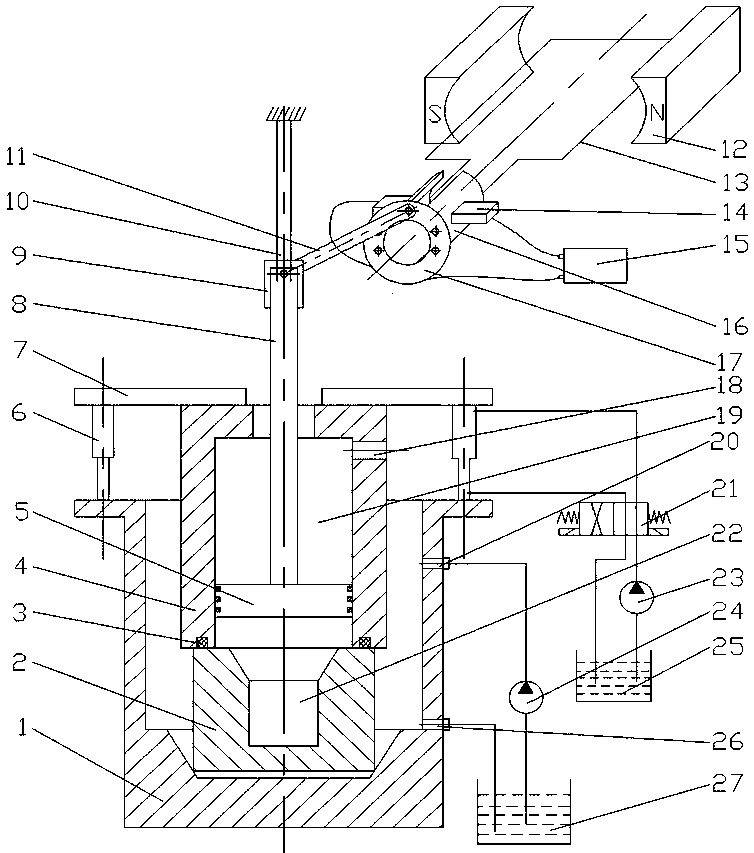

[0014] figure 1 As shown, the present invention has a cylinder body 1, and the bottom in the cylinder body 1 vertically places the workpiece 2. There is a groove at the bottom of the cylinder body 1, and the lower end of the workpiece 2 is placed in the groove, which facilitates the positioning of the workpiece 2.

[0015] The workpiece 2 is provided with a taper hole 22, and the large end of the taper hole 22 faces directly above, and the taper hole 22 is filled with liquid during work. Right above the workpiece 2 is a top cover 4, the center of the top cover 4 has a top cover through hole 19, the top cover through hole 19 communicates with the taper hole 22, and the central axes of the two are collinear. The inner diameter of the top cover through hole 19 is greater than the inner diameter of the large end of the tapered hole 22 . Piston 5 is installed in top cover through hole 19, and piston 5 is connected with the inner side wall of top cover through hole 19 sealingly an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com