Dynamic weight checking scale suitable for dust explosion prevention

A dust and dynamic technology, applied in special scales, packaging automatic control, measuring devices, etc., can solve problems such as unusable, and achieve the effect of preventing dust explosion accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

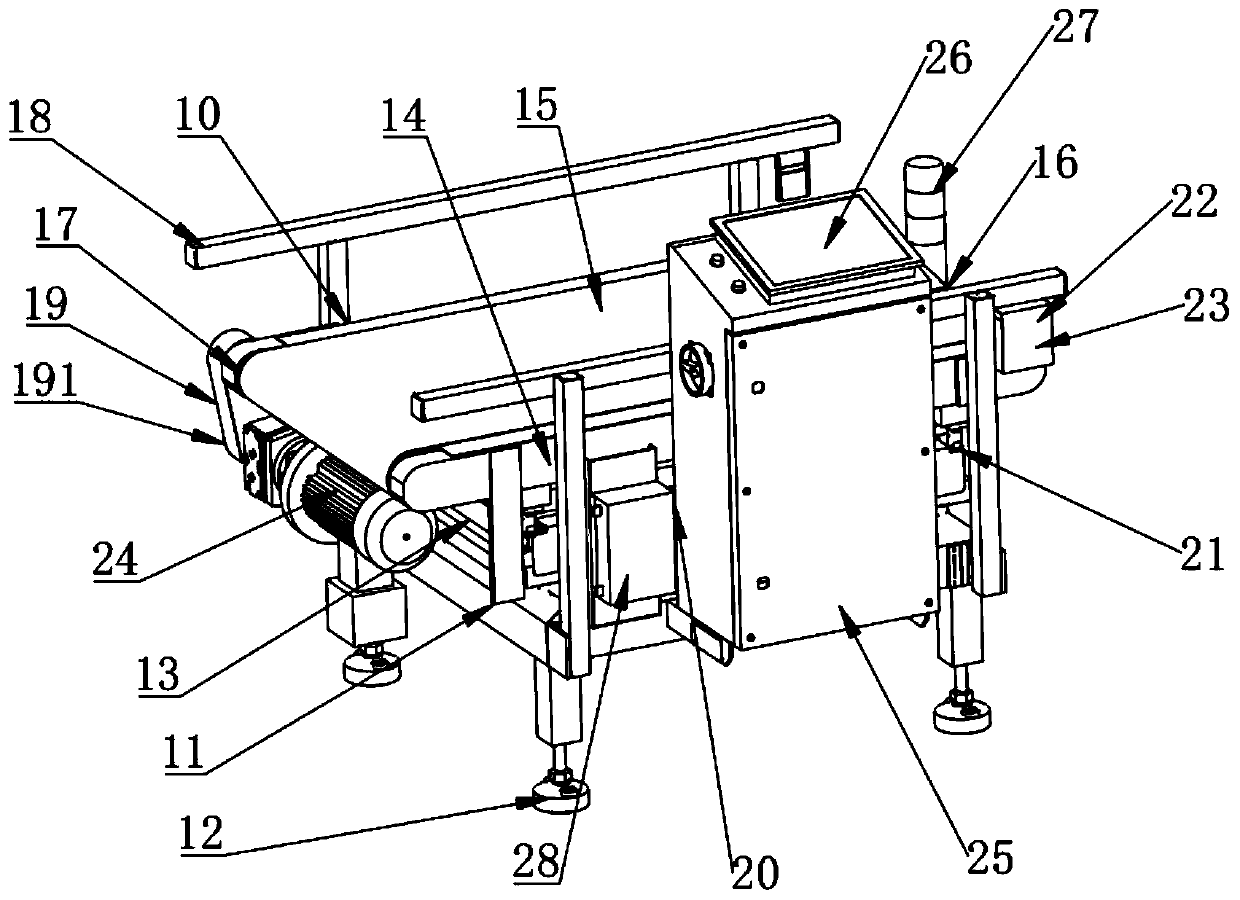

[0011] Such as figure 1 As shown, this specific embodiment adopts the following technical solutions: a dynamic weight loss scale suitable for dust explosion protection, including a scale body 10 and a dust explosion-proof system 20; Support 13, sensor upper support 14, conveyor belt 15, driven shaft 16, driving shaft 17, outer frame 18, chain 19 and chain protection cover 191; described dust explosion-proof system 20 comprises explosion-proof weighing sensor 21, photoelectric eye 22 , photoelectric eye explosion-proof casing 23 and explosion-proof motor 24; Described ground pin 12 is four, is connected around support frame 11 bottom by thread; Described sensor mounting bracket 13 is fixedly connected on the top of support frame 11, and described sensor An explosion-proof weighing sensor 21 is provided on the mounting bracket 13; the upper bracket 14 of the sensor is arranged on the top of the explosion-proof weighing sensor 21, and the driven shaft 16 and the driving shaft 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com