Detection device and method for ocean non-coking flexible pipeline outer sheath layer damage

A flexible pipeline and damage detection technology, applied in the direction of measuring device, fluid tightness test, machine/structural component test, etc., can solve the problems of large amount of funds, low efficiency, affecting production schedule, etc., to achieve cheap facilities and high efficiency , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

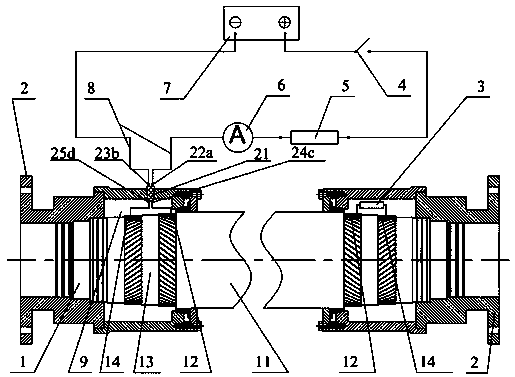

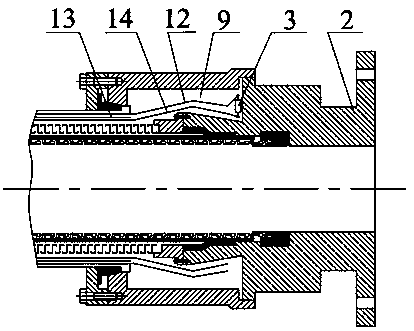

[0026] The present invention provides such Figure 1-5 A device and method for detecting damage to the outer sheath of a marine non-bonded flexible pipeline, including a marine non-bonded flexible pipeline (1), a joint (2), a load resistor (3), a switch (4), and a protective resistor (5), ammeter (6), power supply (7), electric wire (8), sealing plug (21), described marine non-adhesive flexible pipe (1) is connected with joint (2) at both ends respectively , the load resistance (3) communicates with the outer tensile armor wire (12) and the inner tensile armor wire (14) at the tail end of the marine non-bonded flexible pipeline (1), and the positive and negative electrodes of the electric wire (8) are respectively Connect the first electrode (22a) and the second electrode (23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com