High-strength, light, adjustable and horizontal metal road covering plate

A high-strength, level-adjusting technology, applied in the direction of roads, roads, special pavements, etc., can solve the problems of poor connection, dismantling, maintenance difficulties, and uneven laying, so as to reduce labor intensity of workers, save hoisting and transportation costs, The effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

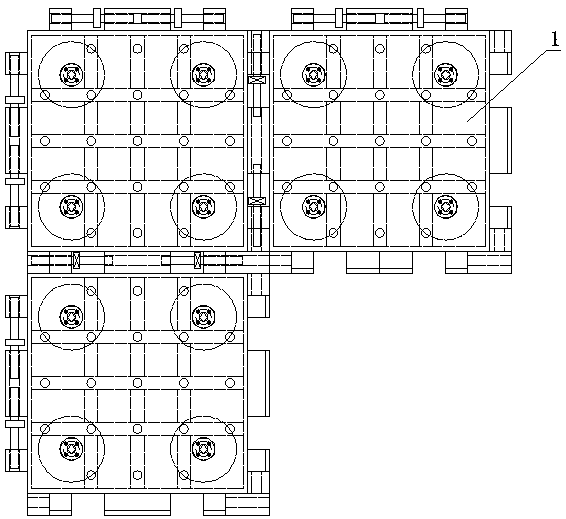

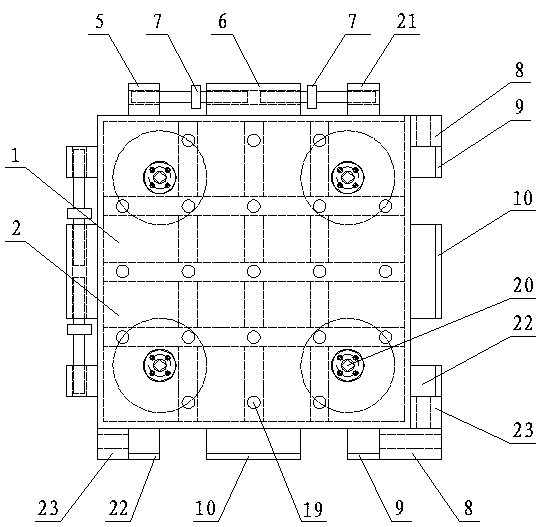

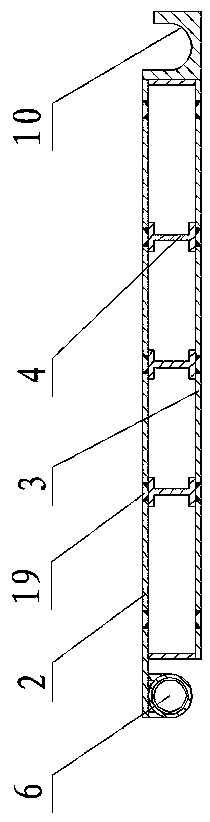

[0020] Such as Figure 1-5 Shown, a kind of high-strength lightweight adjustable horizontal metal backing plate of the present invention, as figure 1 , image 3 As shown, it is composed of plate body 1 connected sequentially. Board body 1 includes cover plate 2, bottom plate 3 and I-shaped steel frame 4. Cover plate 2 and bottom plate 3 are made of high-strength aluminum alloy plates, and I-shaped steel frame 4 is made of high High-strength aluminum alloy I-beam material, the hardness and toughness of this material is higher than that of carbon steel, the specific gravity is 1 / 3 of carbon steel, very light, transporting this product in one car is equivalent to transporting three cars of carbon steel products; on the cover plate 2 There are horizontally arranged I-shaped steel skeletons 4 and vertically arranged I-shaped steel skeletons 4 welded between the bottom plate 3, and the corresponding positions of the cover plate 2 and the bottom plate 3 are provided with welding ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com