Sliding stop structure

A stop and slip technology, applied in special positions of vehicles, vehicle seats, vehicle parts, etc., can solve problems such as inability to effectively provide stop resistance, large layout space requirements, and complex slide rail structures. Conducive to handling, strong structural tolerance, and the effect of enhancing the sense of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

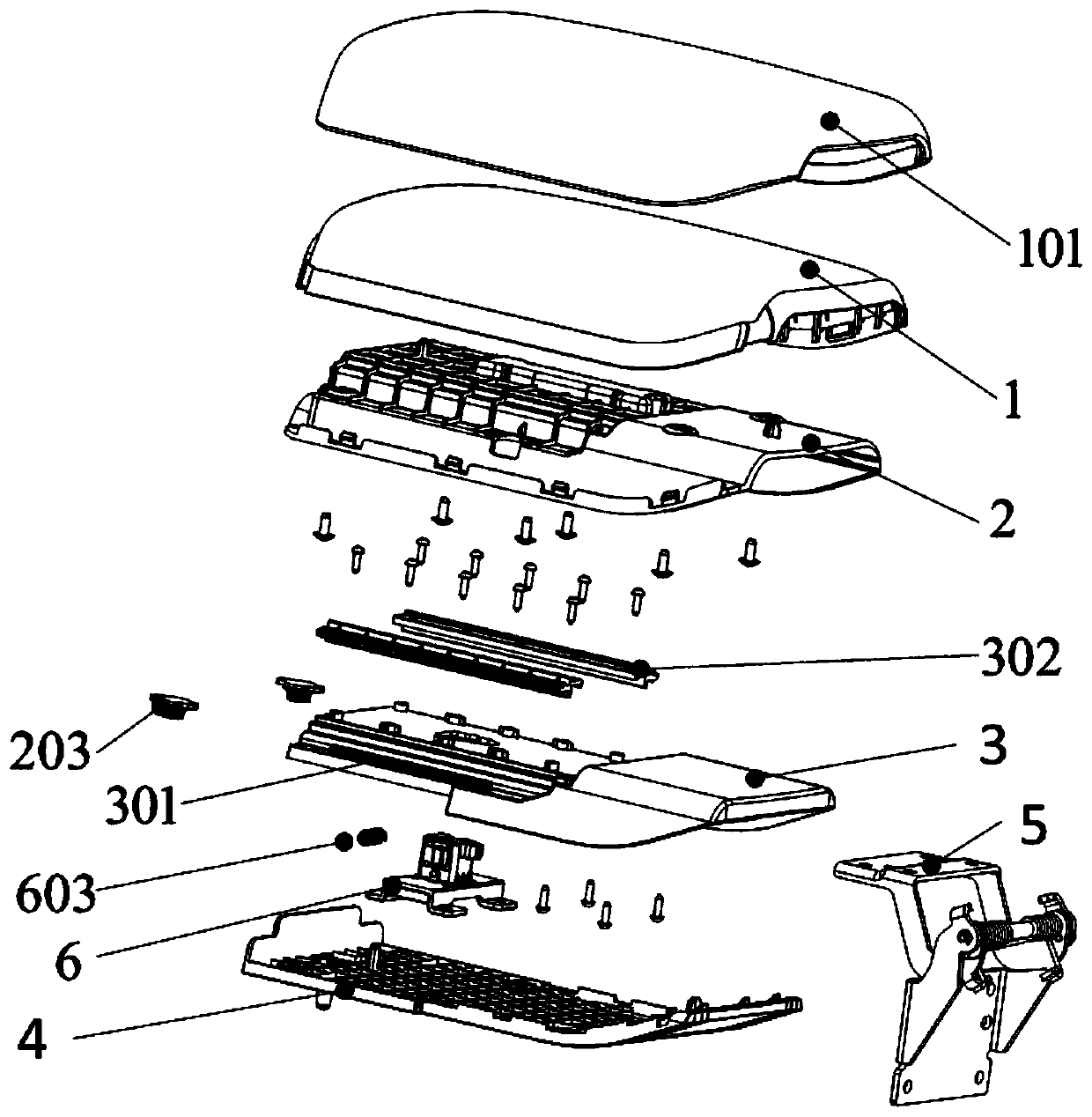

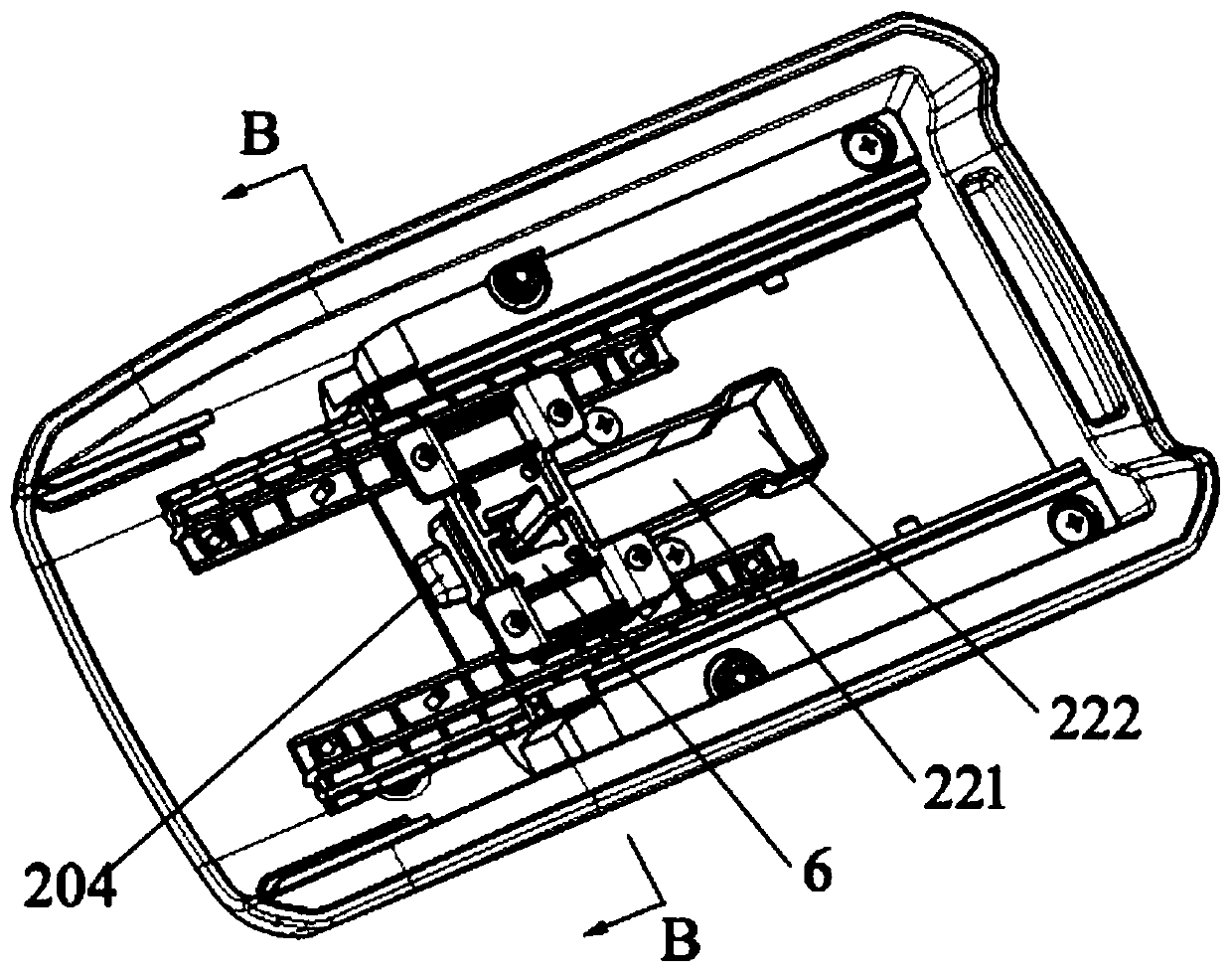

[0025] Such as Figure 1-8 As shown, a sliding stop structure includes a sliding plate 2 and a fixed frame 3 that realize sliding fit through a sliding mechanism. The upper end of the sliding plate 2 is also fixed with an armrest cover 1 , and a skin 101 is laid on the upper end of the armrest cover. , the lower end of the fixed frame 3 is fixed with a handrail bottom plate 4, and the hinge 5 is also used to realize the hinge connection between the handrail and the lower box body, so as to realize the turning function of the handrail; the handrail also includes a stop mechanism and a slip damping mechanism, and the stop mechanism includes The spring damping base 6 and the stop sliding groove 202 fixed on the sliding plate 2 and the fixed skeleton 3, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com