A positioning tool for shielding ring and insert welding

A technology for positioning tooling and shielding rings, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., which can solve problems such as decreased production efficiency, inaccurate positioning, and inability to accurately align the center circle of the insert section.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

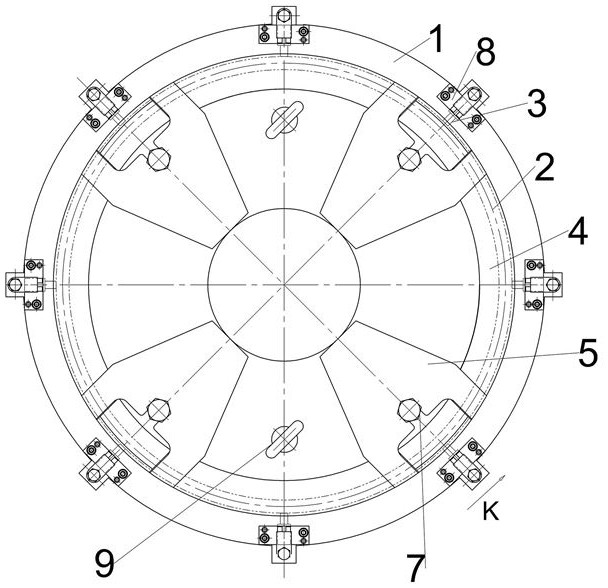

[0029] The specific embodiment of the positioning tool for shielding ring and insert welding of the present invention, as figure 1 As shown, the positioning tool includes a base plate 1, which is a circular plate and has a central axis extending in the up-down direction. In this embodiment, the plane where the upper surface of the base plate 1 is located is set as the reference plane, and the reference plane is set for It can unify the positioning and installation datum of each component, ensure the unification of the datum and then ensure the accuracy of the positioning of the overall structure.

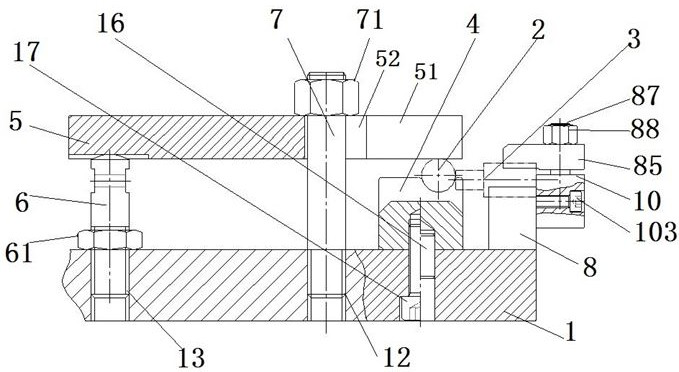

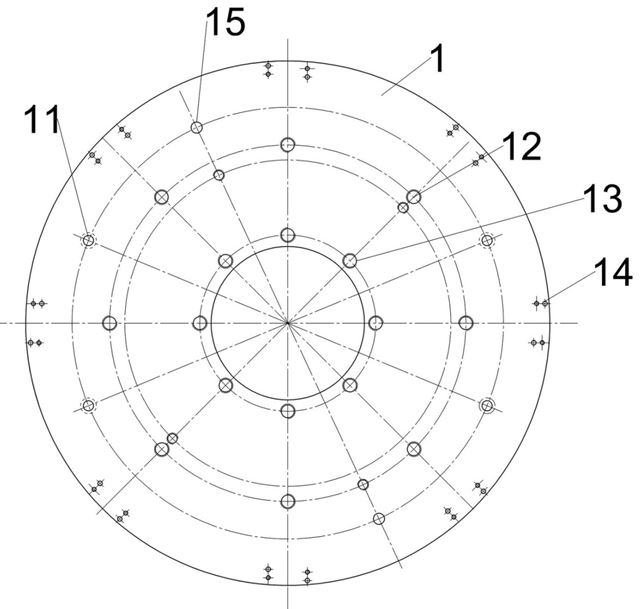

[0030] like figure 1 , figure 2 and image 3 As shown, the upper plate surface of the bottom plate 1 is located at the middle position in the radial direction and is provided with a positioning ring 4. The positioning ring 4 is circular, and positioning pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com