Wheel cooler

A technology for coolers and wheels, which is applied in the direction of cooling brakes, wheels, brakes, etc., can solve the problems of complex manufacturing process and high manufacturing cost of wheel radiators, and achieve the effects of lowering temperature, lowering manufacturing costs, and reducing unnecessary losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

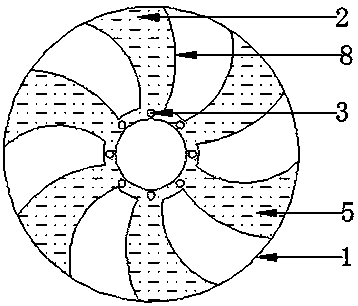

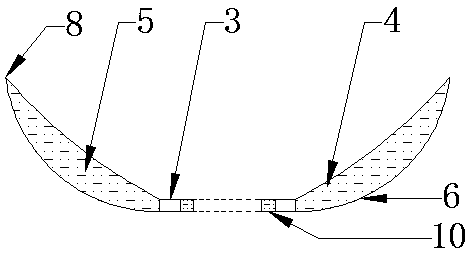

[0038] like figure 1 , figure 2 The wheel cooler shown includes a fan blade inner shell 4 , a fan blade outer shell 6 , a heat-conducting working medium 5 , a fixing bar 1 , and a bracket 10 .

[0039] The manufacturing materials of the fan blade inner shell 4 and the fan blade outer shell 6 are metal plates.

[0040] The blade casing 6 is a circular metal plate with a hollow center, and the outer shape of the blade casing 6 is U-shaped.

[0041] The fan blade inner shell 4 is a circular metal plate with a hollow center, and the appearance shape of the fan blade inner shell 4 is U-shaped.

[0042] The fan blade inner shell 4 is stamped and formed by a punch through a mold, and 8 screw ports 3 are stamped on the hollow side of the fan blade shell 6, and there are 6 groups of wind blades on the stamped fan blade inner shell 4.

[0043] The central part of the fan blade on the fan blade inner shell 4 is convex.

[0044] The fan blade shell 6 is stamped and formed by a punch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com