Zipper

A technology of zipper and zipper teeth is applied to zipper. It can solve the problems of reduced zipper tape performance, zipper waste zipper tape, zipper disengagement, etc., to achieve the effect of improving sealing and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

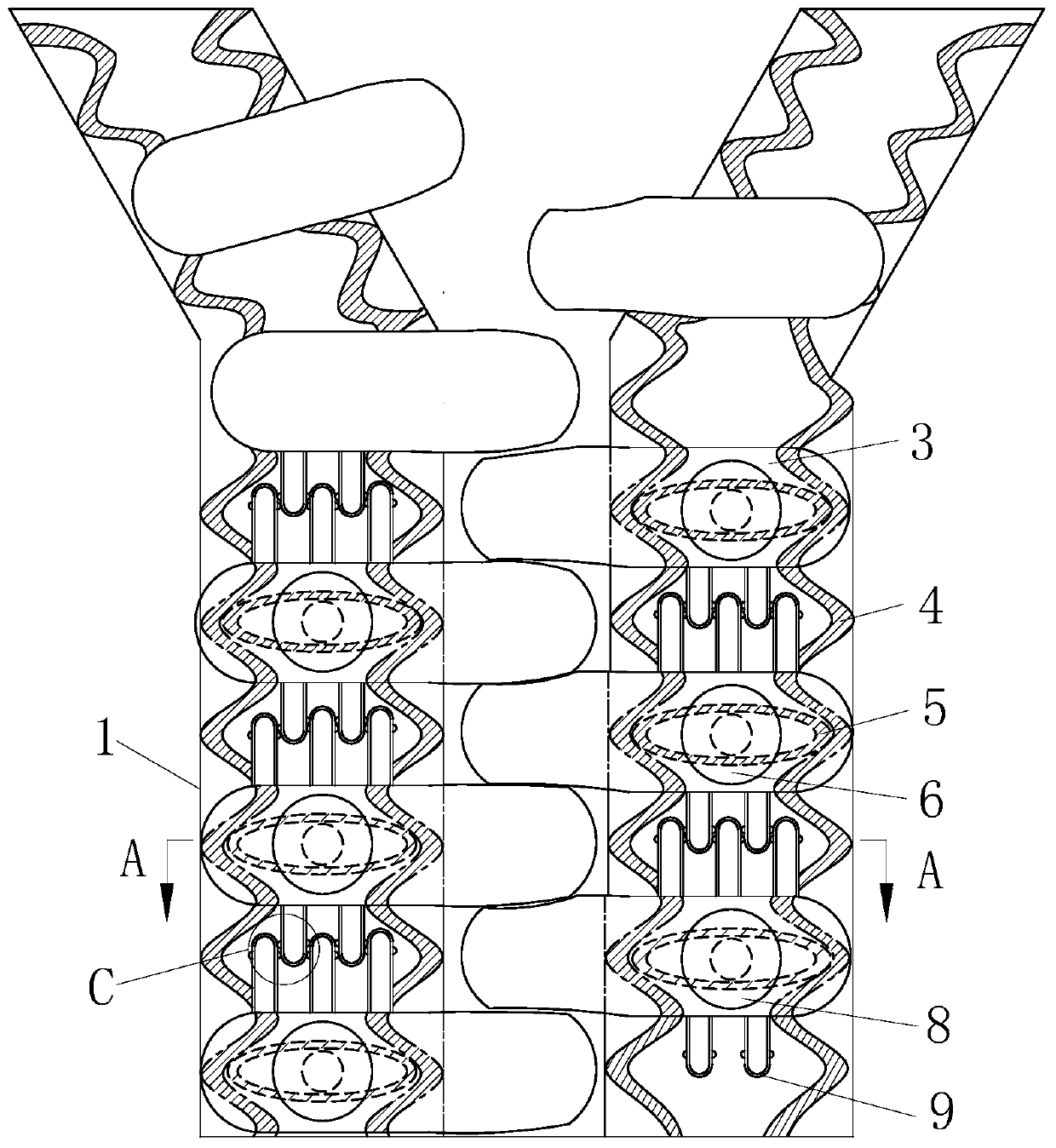

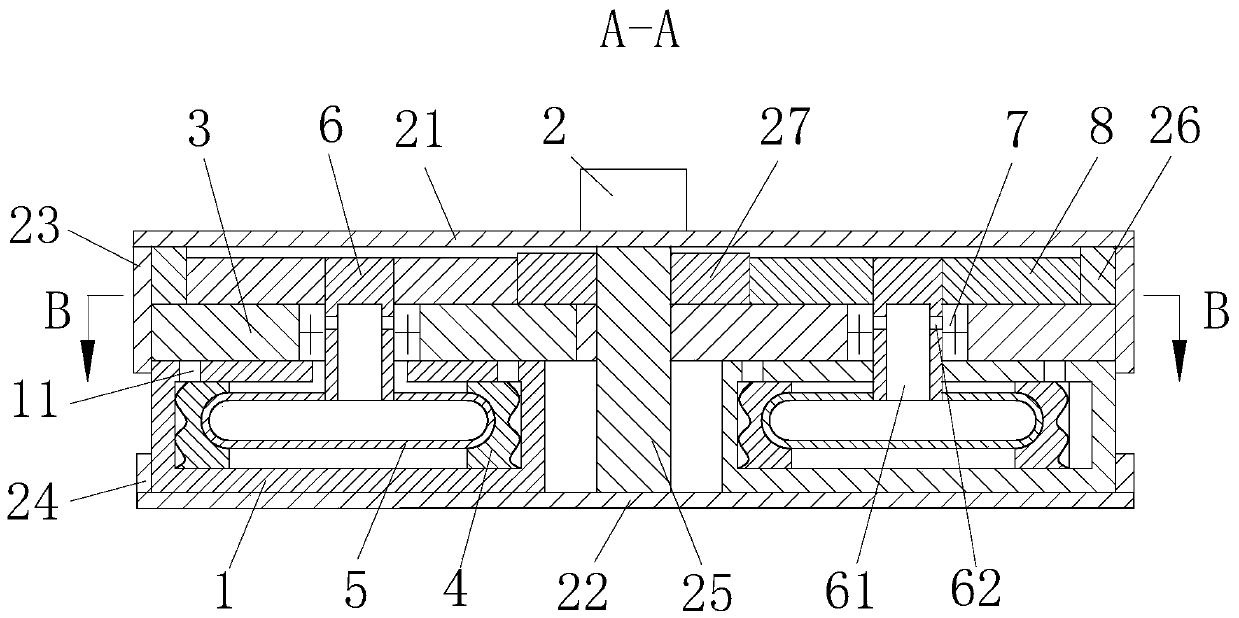

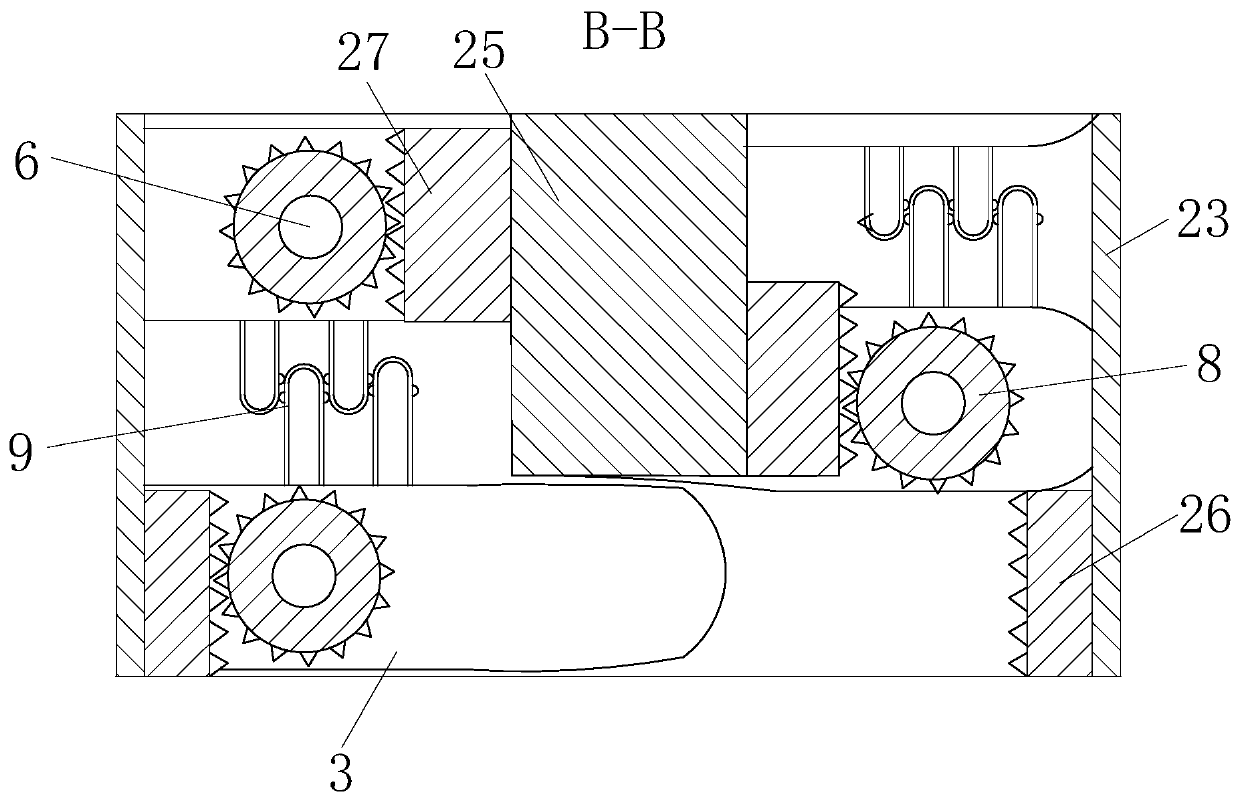

[0022] use Figure 1-Figure 6 A slide fastener according to one embodiment of the present invention will be described below.

[0023] Such as figure 1 , figure 2 and image 3 As shown, a slide fastener according to the present invention includes a slide fastener tape 1, a slide fastener puller 2 and a slide fastener element 3; The feature is that: the zipper tape 1 is provided with a cavity, and elastic corrugated plates 4 are installed on both sides of the cavity; There is a rotating rod 6; the zipper teeth 3 are arranged on the upper surface of the zipper tape 1, and the zipper teeth 3 are connected with the rotating rod 6 through the bearing 7; the rotating rod 6 passes through the zipper teeth 3 and is connected with a rotating wheel 8; The zipper slider 2 includes an upper top plate 21, a lower bottom plate 22, a first vertical plate 23, a second vertical plate 24 and a connecting column 25; The end surface is provided with a first vertical plate 23, and the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com