Fuel injector arrangement

A fuel injector and assembly technology, which can be applied to fuel injection devices, special fuel injection devices, fuel injection devices with oil reservoirs, etc., can solve problems such as consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

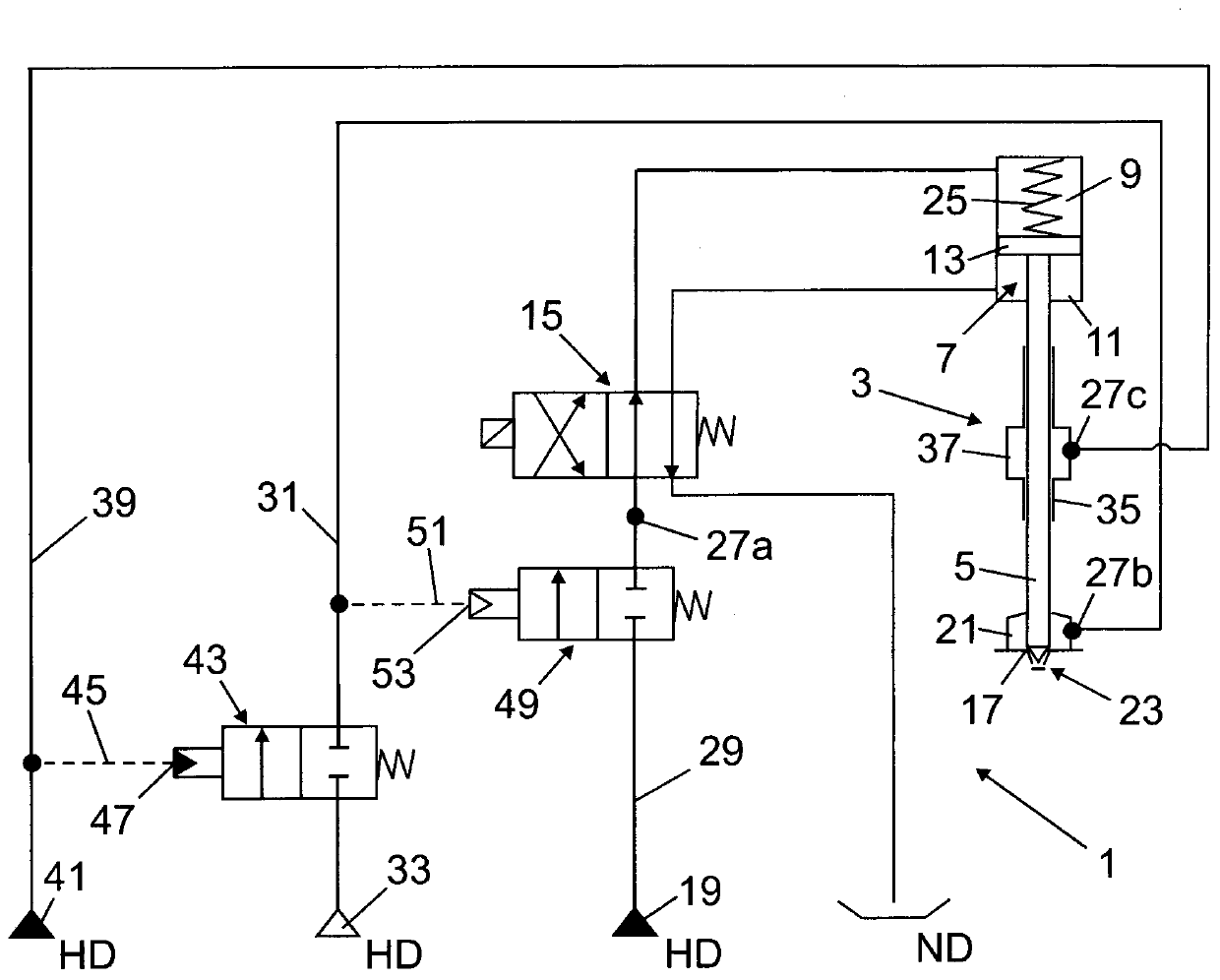

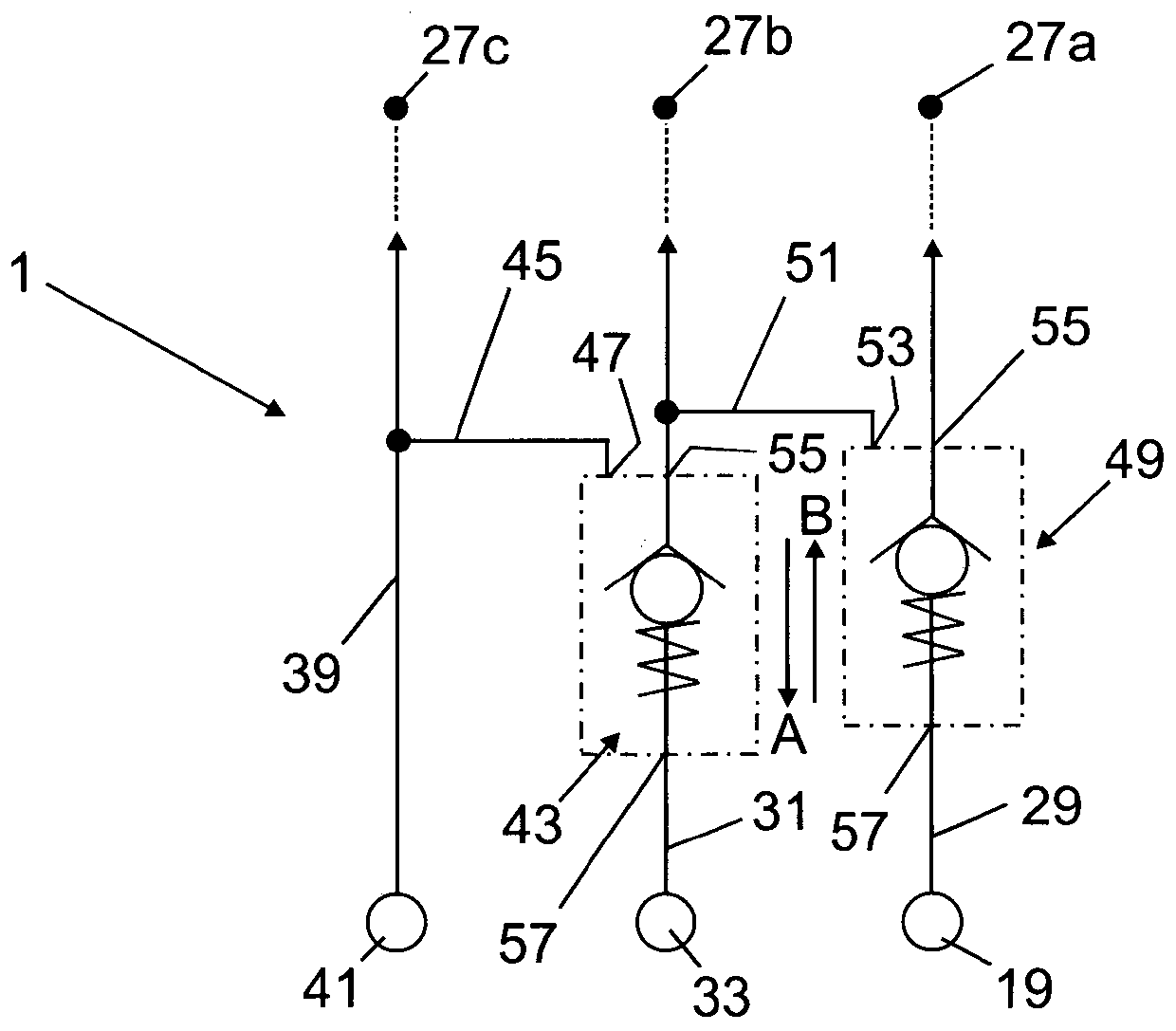

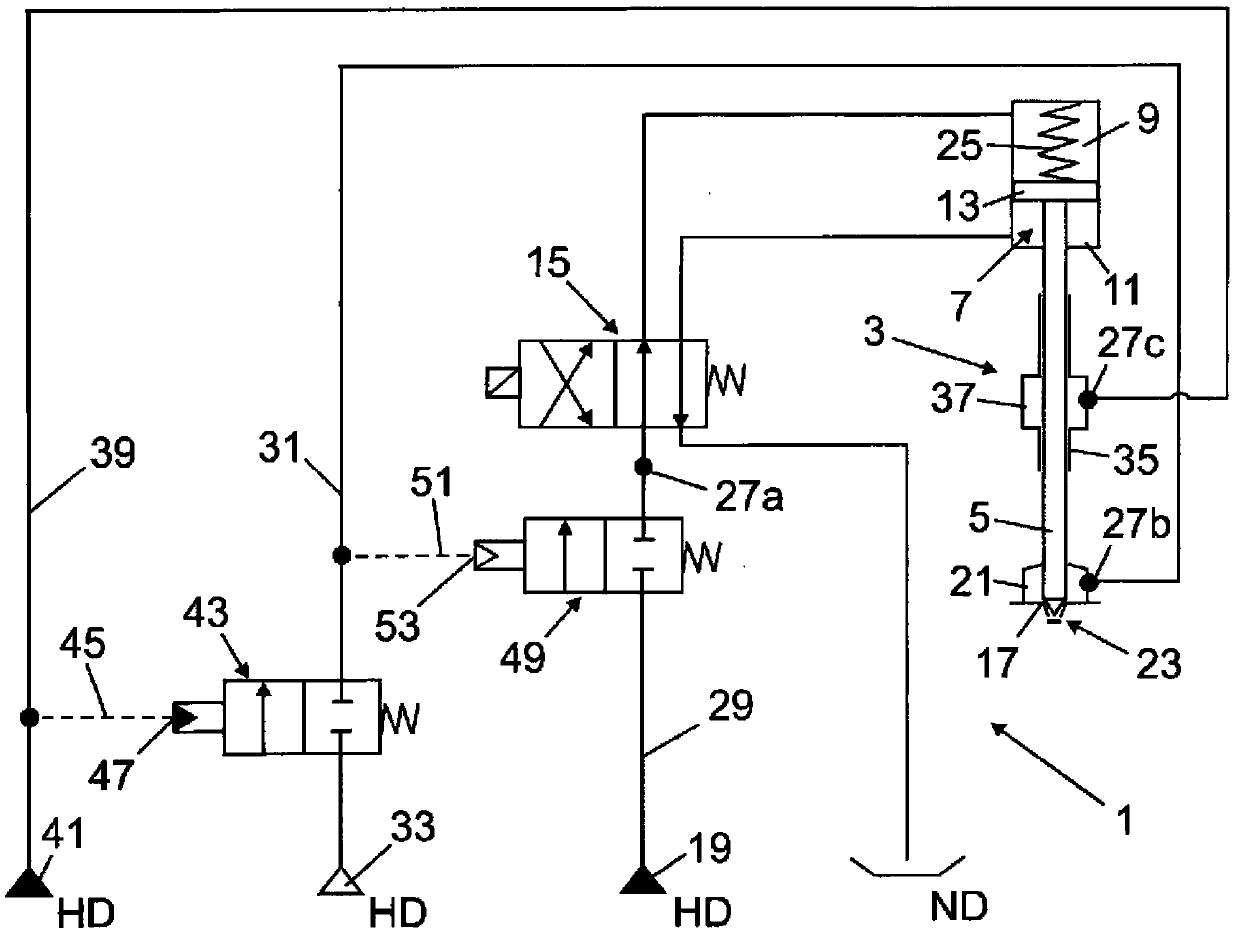

[0036] figure 1 A fuel injector assembly 1 is shown which has, inter alia, a fuel injector 3 which is provided for injecting gas. The fuel injector 3 comprises at least one gas nozzle valve element 5, preferably also a liquid fuel nozzle valve element (in figure 1 The gas nozzle valve element 5) is shown only by way of example. The fuel injector 3 is preferably a dual-fuel fuel injector, that is to say designed for injecting gas and liquid fuel.

[0037] For controlling the gas nozzle valve element 5, the fuel injector 3 has a piston control assembly 7 comprising a first control chamber 9 and a second control chamber 11 between which the hydraulic reciprocating control of the piston is possible. The piston 13 of the control unit 7 , which is connected to the gas nozzle valve element 5 , that is to say via a corresponding pressure loading and depressurization of the control chambers 9 , 11 by means of the control fluid. In order to direct the control fluid to and from the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com