High-viscosity fluid-oriented reusable liquid level detection head

A liquid level detection, high viscosity technology, applied in the direction of displaying the liquid level indicator through pressure measurement, etc., can solve the problems of difficult liquid level detection of high viscosity fluids and the inability to use the high viscosity fluid liquid level detection device repeatedly, so as to improve the accuracy Effects of Sex and Safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach I

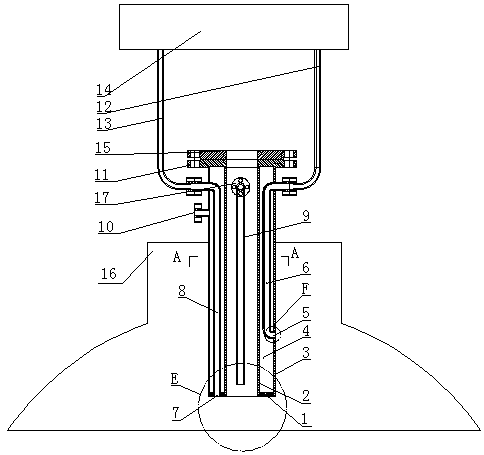

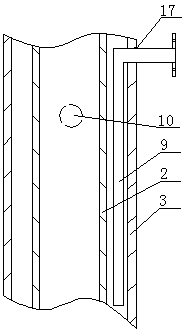

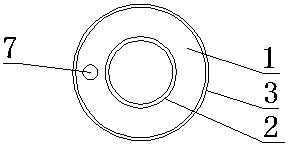

[0029] Specific implementation mode I: as figure 1 -6, the interlayer vertical pipe includes an annular head 1, an inner sleeve 2, an outer sleeve 3, an interlayer vertical pipe flange 11, a heat source inlet 10, a heat source outlet 17, and a heat source outlet pipe 9; wherein, the inner sleeve 2 Coaxially arranged in the outer casing 3; one end of the inner casing 2 and the outer casing 3 is arranged on the interlayer vertical pipe flange 11 at the same time; the other end of the inner casing 2 and the outer casing 3 is sealed by the ring head 1 so that the inner The casing 2, the outer casing 3, the annular head 1 and the interlayer vertical pipe flange 11 together form a closed annular space; wherein, the heat source inlet 10 and the heat source outlet 17 are all arranged on the side wall of the outer casing 3; the heat source outlet 17 The heat source inlet 10 is arranged closer to the interlayer vertical pipe flange 11 and the angle between the heat source outlet 17 and ...

specific Embodiment II

[0034] Specific embodiment II: Both the trachea A6 and the trachea B8 in the above specific embodiment I may be in contact with high-viscosity fluid, which increases the probability of blockage, and can be improved on the basis of specific embodiment I.

[0035] Such as Figure 7-10, the sandwich vertical pipe includes an annular head 1, an inner casing 2, an outer casing 3, a sandwich vertical pipe flange 11, a heat source inlet 10, a heat source outlet 17, and a heat source outlet pipe 9; wherein, the inner casing 2 Coaxially arranged in the outer casing 3; one end of the inner casing 2 and the outer casing 3 is arranged on the interlayer vertical pipe flange 11 at the same time; the other end of the inner casing 2 and the outer casing 3 is sealed by the ring head 1 so that the inner The casing 2, the outer casing 3, the annular head 1 and the interlayer vertical pipe flange 11 together form a closed annular space; wherein, the heat source inlet 10 and the heat source outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com