Cooling tank for rubber production

A cooling tank and rubber technology, applied in the field of rubber production, can solve the problem of inconvenient use of the cooling tank, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

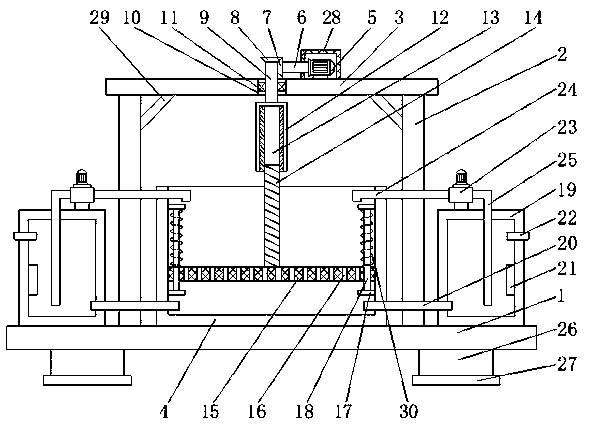

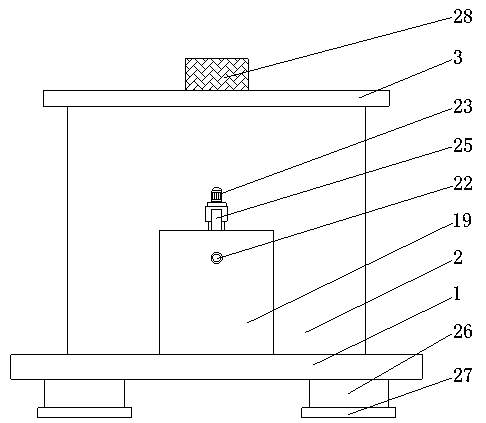

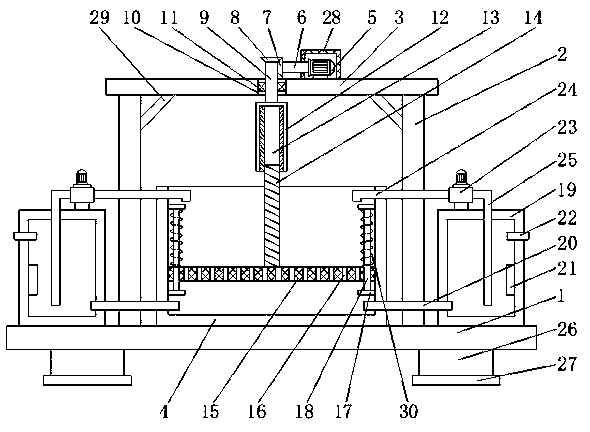

[0018] The first embodiment: please refer to Figure 1-2 , A cooling tank for rubber production, including a bottom plate 1, the left and right sides of the top of the bottom plate 1 are fixedly connected with support plates 2, the tops of the two support plates 2 are fixedly connected by the top plate 3, the left and right sides of the bottom of the top plate 3 are located The position between the two support plates 2 is fixedly connected to the limit rod 29, and the end of the limit rod 29 away from the top plate 3 is fixedly connected to the support plate 2. The top plate 3 and the support plate 2 are reinforced by setting the limit rod 29 The top of the bottom plate 1 and the position between the two support plates 2 is fixedly connected with a cooling shell 4, the top of the top plate 3 is fixedly connected with a drive motor 5, and the output shaft of the drive motor 5 is fixedly connected with a drive shaft 6, The top of the top plate 3 is provided with a dust-proof hous...

Example

[0021] The second embodiment: as described in claim 1, a cooling tank for rubber production, comprising a bottom plate 1, the left and right sides of the top of the bottom plate 1 are fixedly connected with support plates 2, and the tops of the two support plates 2 pass The top plate 3 is fixedly connected, the top of the bottom plate 1 and the position between the two supporting plates 2 is fixedly connected with a cooling shell 4, the top of the top plate 3 is fixedly connected with a drive motor 5, and the output shaft of the drive motor 5 A drive shaft 6 is fixedly connected to the upper part, a first gear 7 is fixedly connected to the left side of the drive shaft 6, a second tooth 8 is provided on the left side of the first wheel 7, and the first gear 7 and the second gear 8 are meshed with each other, the bottom of the second gear 8 is fixedly connected with a fixed rotating shaft 9, the top of the top plate 3 is provided with a through groove 10 that is adapted to the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com