An industrial template grinding machine

A grinding machine and template technology, which is applied in the direction of grinding machine parts, grinding machines, manufacturing tools, etc., can solve the problems of drawing needle collision, waste of grinding head resources, dust particle pollution, etc., to increase performance, improve service life, The effect of high grinding uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

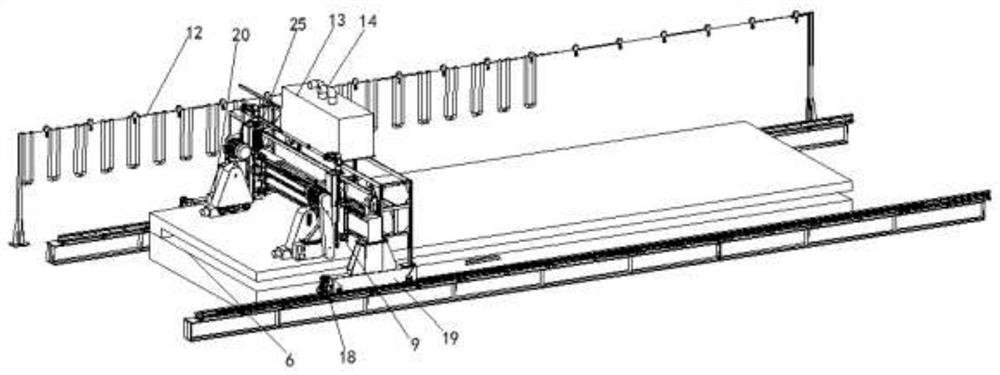

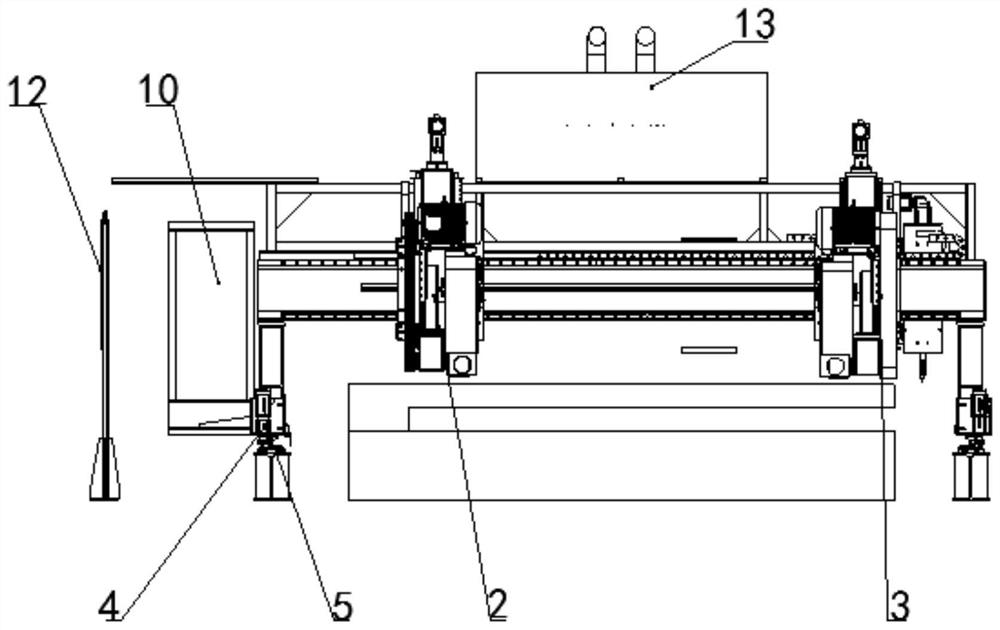

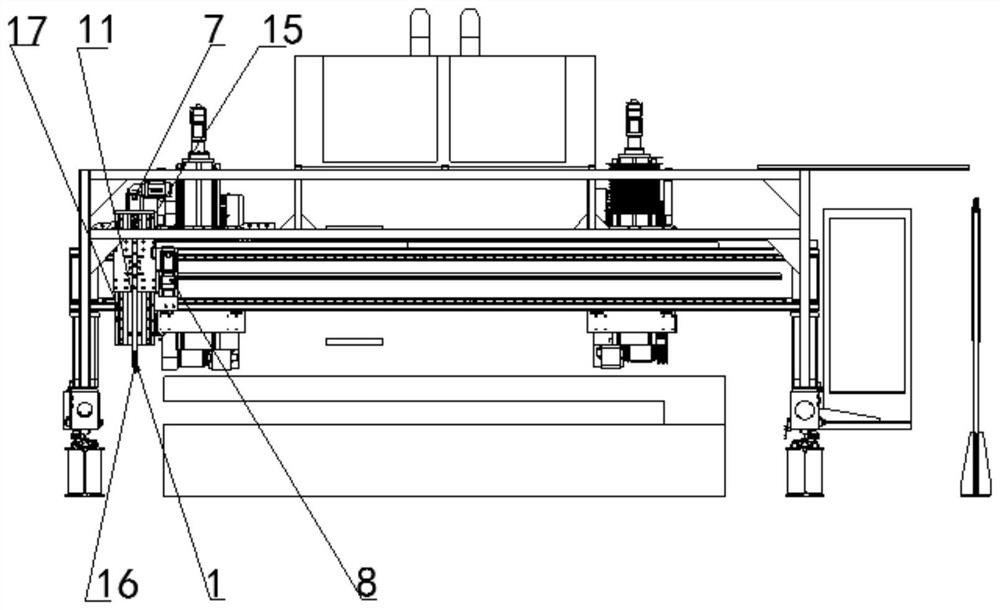

[0021] Refer to attached Figure 1-4 , an industrial template grinding machine is characterized in that it includes a scribing grinding head 1, a first abrasive belt grinding head 2, a second abrasive belt grinding head 3, a machine walking mechanism 4 and a heavy-duty track 5, and the first abrasive belt The grinding head 2 and the second abrasive belt grinding head 3 are arranged symmetrically with respect to the center of the workbench 6, and the scribing grinding head 1, the first abrasive belt grinding head 2 and the second abrasive belt grinding head 3 respectively pass through the corresponding grinding head The lifting mechanism 7 is connected with a grinding head traveling mechanism 8, the grinding head traveling mechanism 8 is controlled and connected with the electrical cabinet 10 through a servo motor 9, one end of the marking grinding head 1 is connected with a line rail mechanism 12 through a synchronous rod 11, and the working A machine traveling mechanism 4 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com