Reagent shaking-up and lifting equipment

A technology for lifting equipment and reagents, applied in the direction of dissolution, mixers, chemical instruments and methods, etc., can solve the problems of low efficiency and complicated mixing operation of reagent mixing equipment, and achieve practical, convenient and adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

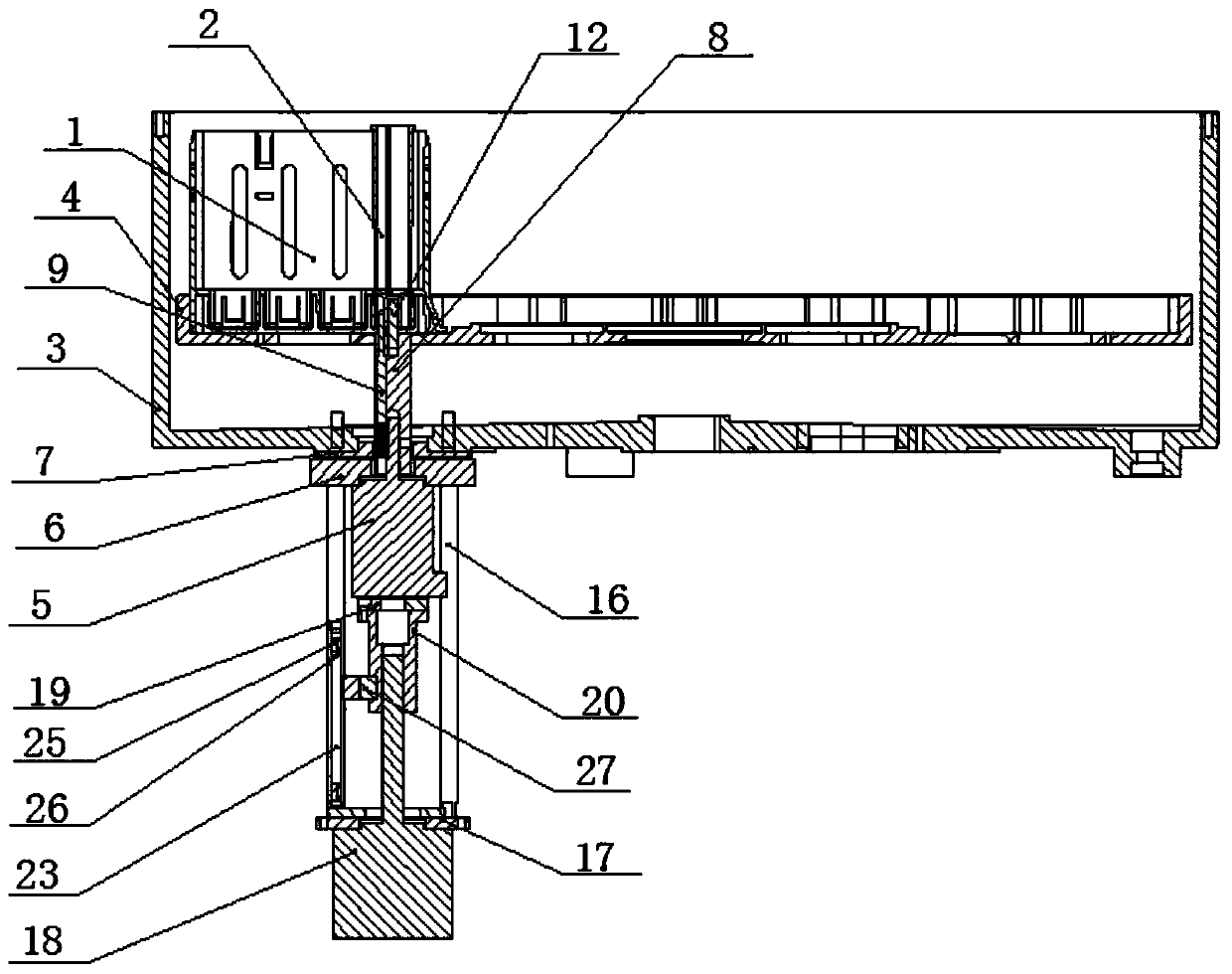

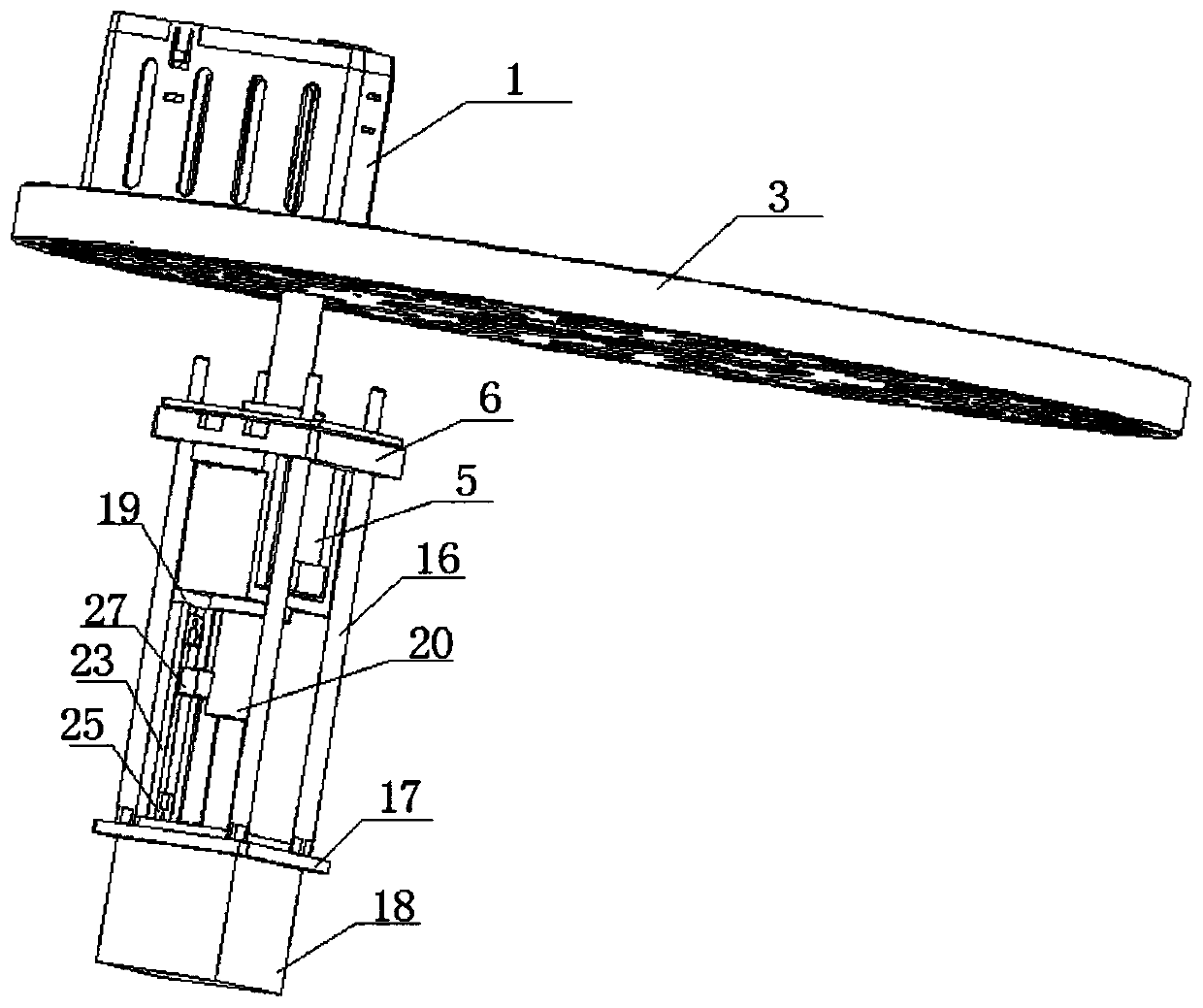

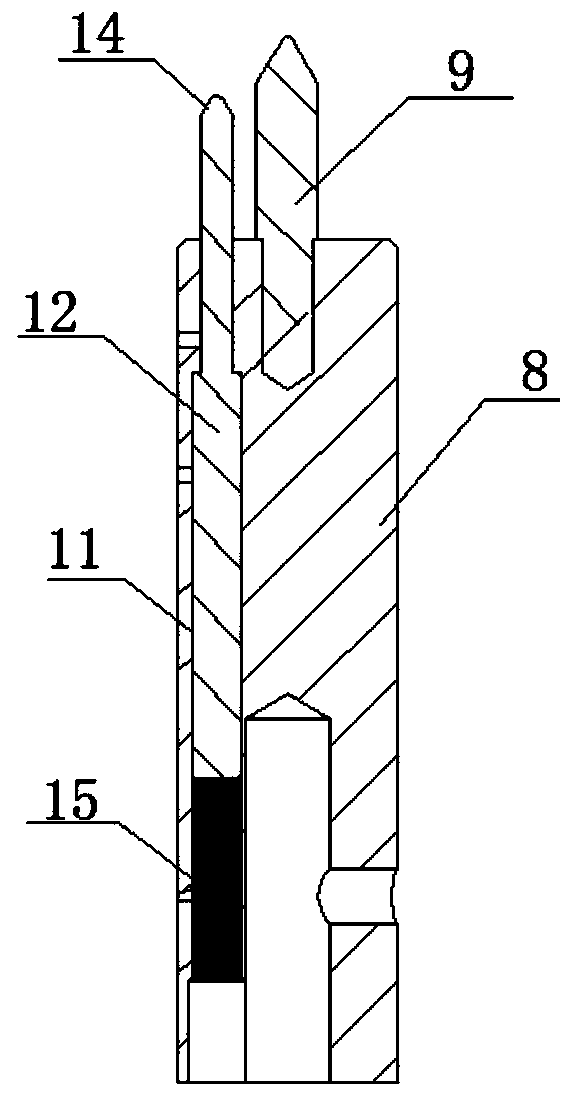

[0025] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0026] Such as figure 1 and figure 2 As shown, the present invention includes a reagent box 1 and a reagent bottle 2 installed on the reagent box 1, and the structural relationship between the reagent bottle 2 and the reagent box 1 refers to the structural relationship between the round reagent bottle and the reagent box in the patent application number 201510140715.1 ; Reagent box 1 is located in the reagent disk 3, is provided with rotating disk 4 in the reagent disk 3, and reagent box 1 is located on the rotating disk 4, is driven the rotating disk 4 by the motor (not shown) that drives reagent disk 3 to rotate Rotating, the kit 1 can follow the rotating disk 4 to rotate intermittently.

[0027] A first motor 5 is arranged below the reagent tray 3, and the first motor 5 is fixed on the first motor mounting plate 6, and a gasket 7 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com