Ash removal device for dust remover filter cartridges

A technology of dust cleaning device and dust collector, which is applied in the directions of transportation and packaging, dispersed particle filtration, chemical instruments and methods, etc. It can solve the problems of insufficient energy saving and environmental protection, large consumption of filter cartridges, time-consuming and labor-intensive, etc., and improve efficiency , High ash collection efficiency, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

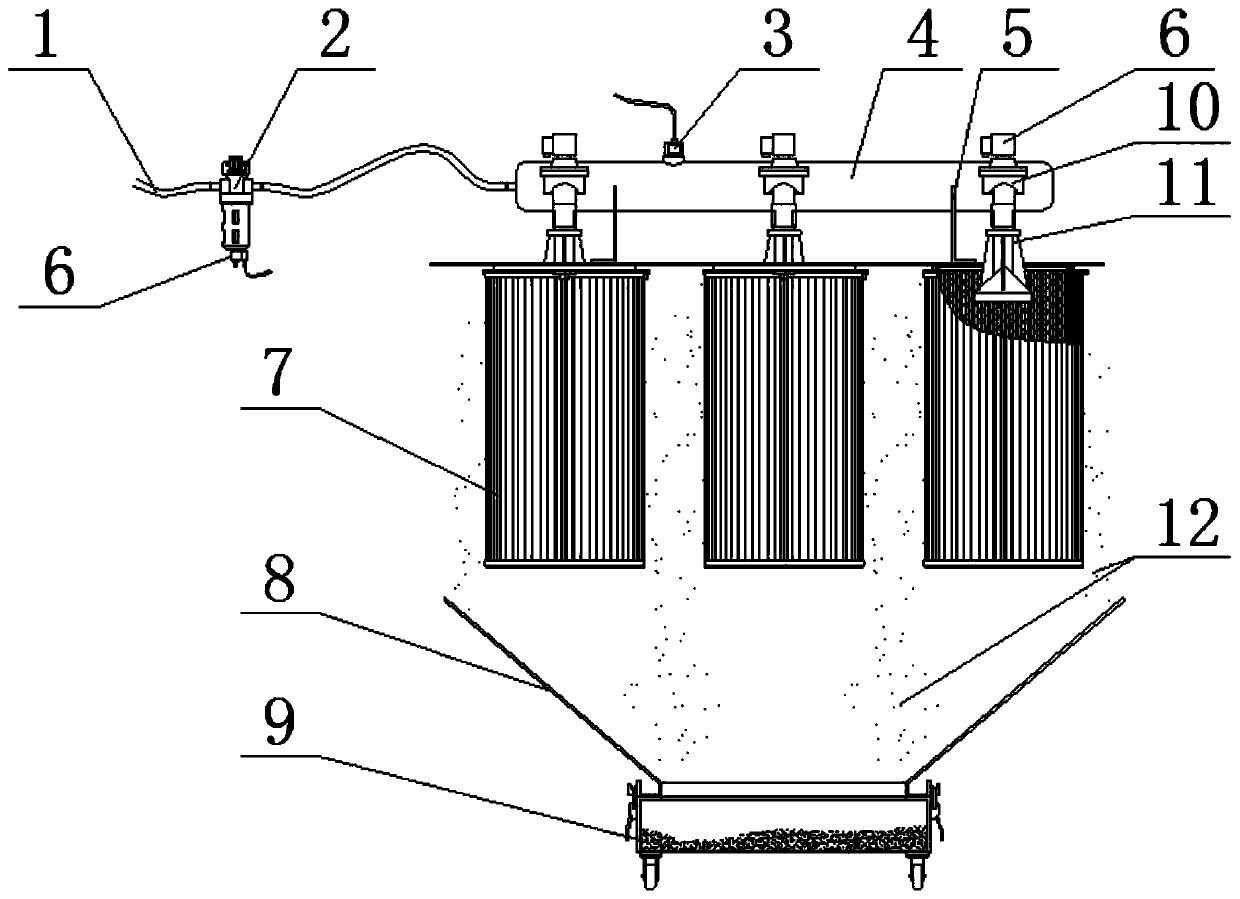

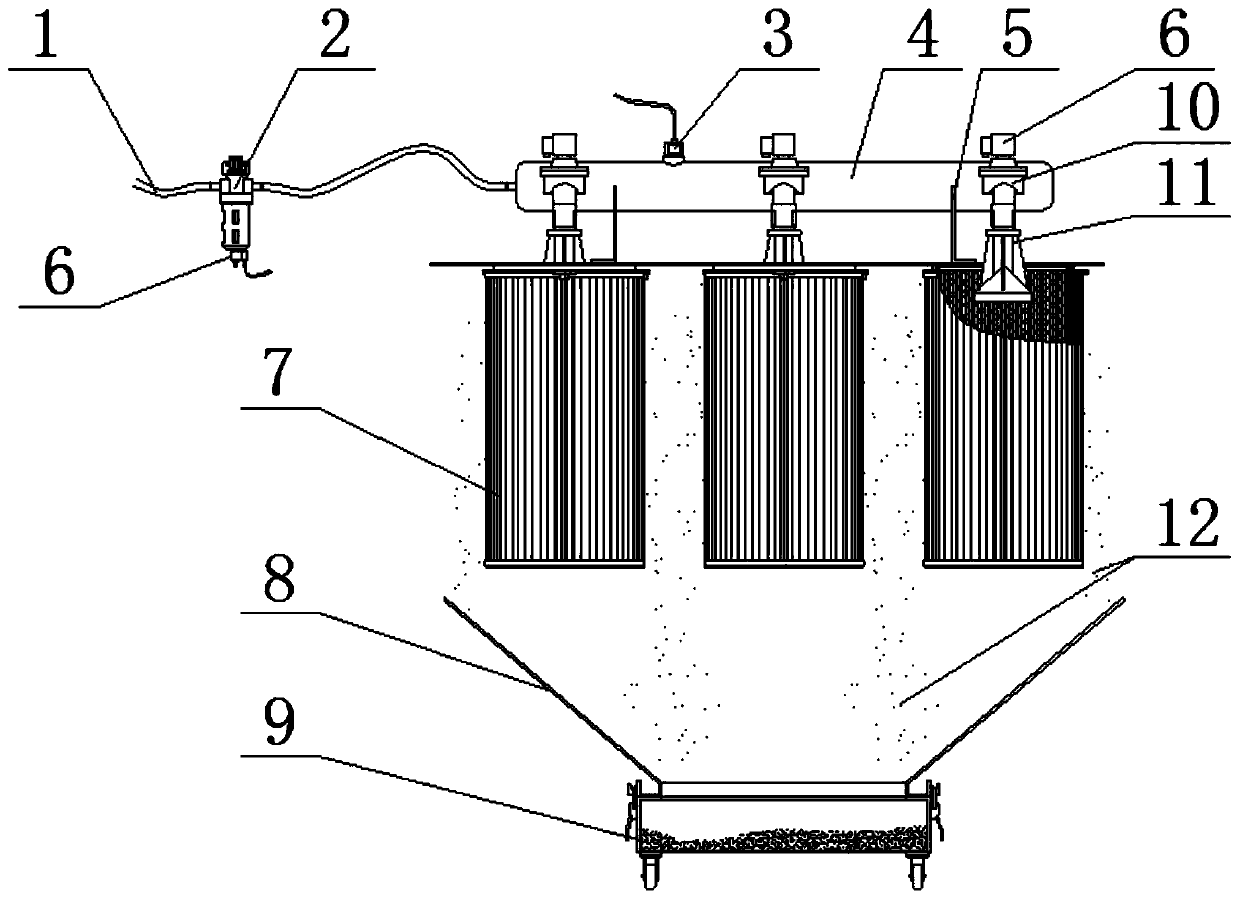

[0022] refer to figure 1 , figure 2 , the present invention includes an oil-water separator 2, an air pressure sensor 3, an air storage tank 4, a bracket 5, a solenoid valve 6, a filter cartridge 7, an inclined ash collecting hopper 8, an ash collecting box 9, an air nozzle 10, a muffler 11, and a body 13 and the controller, the bottom of the body 13 is an inclined ash collecting bucket 8, and the bottom of the inclined ash collecting hopper 8 is equipped with an ash collecting box 9; inside the body 13, a number of filter cartridges 7 are installed through a mounting plate, directly below the filter cartridge 7 It is a sloping ash collecting bucket 8, and an air storage tank 4 is fixed on the top of the mounting plate through a bracket 5, and an air pressure sensor 3 is installed on the air storage tank 4, and the left end of the air storage tank 4 is connected to an oil-water separator 2 through a pipeline A solenoid valve 6 is installed on the top; an air nozzle 10 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com