Quick butt joint fine-tuning device for upper layer and lower layer of steel-concrete combined pipes

A technology of fine-tuning device and combined pipe, applied in the direction of building, building structure, etc., can solve the problems of affecting installation quality, complicated operation, unable to form a stable and unified system, etc., to improve work efficiency, ensure quality and reliability, and improve docking. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

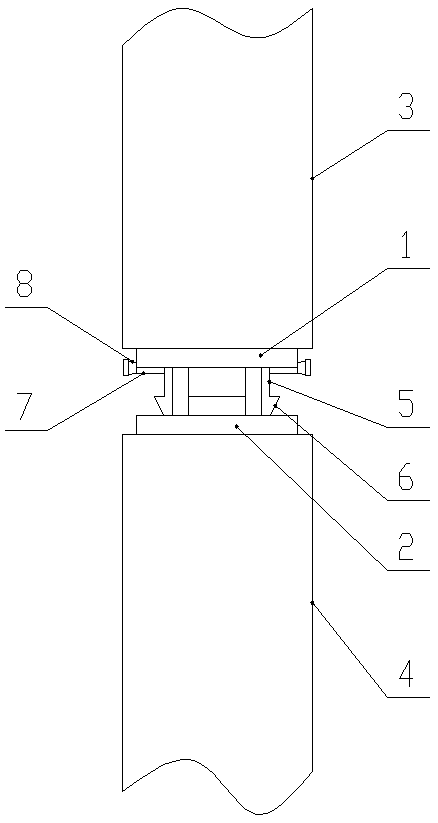

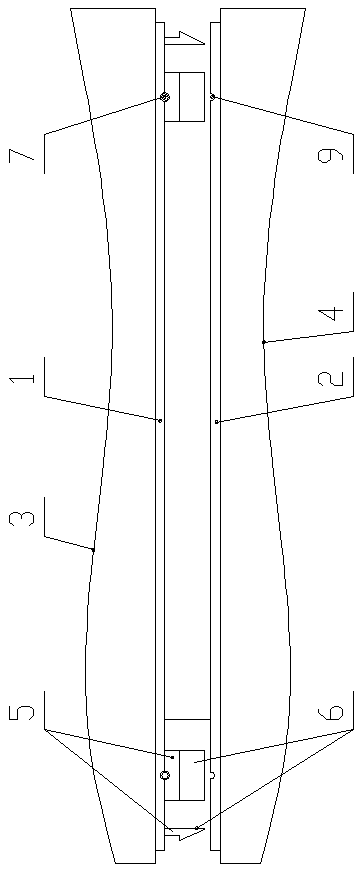

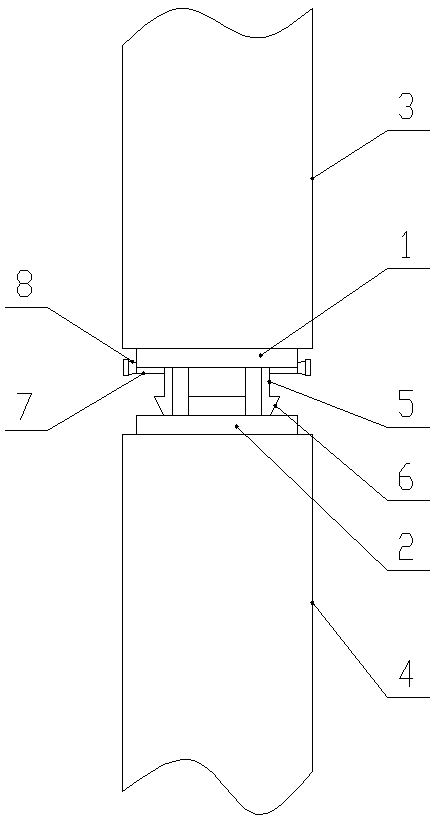

[0013] Such as figure 1 and figure 2 As shown, the fine-tuning device for quick docking of the upper and lower layers of the steel-concrete composite pipe of the present invention includes an upper rectangular flange 1 and a lower rectangular flange 2 arranged horizontally, and the upper side of the upper rectangular flange 1 is welded inside the upper steel-concrete composite pipe 3 The lower end of the rectangular steel plate structure, the lower side of the lower rectangular flange 2 is welded to the upper end of the rectangular steel plate structure inside the lower reinforced concrete composite pipe 4, and the upper rectangular flange 1 and the lower rectangular The rectangular hole corresponding to the cavity, the lower side of the upper rectangular flange 1 is in corresponding contact with the upper side of the lower rectangular flange 2, the inner wall of the rectangular hole of the upper rectangular flange 1 is fixedly provided with several positioning plates 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com