Detergent put-in device and washing machine

A detergent injection and washing machine technology, which is applied in the field of washing machines, can solve the problems of unfavorable popularization, complex structure, difficult to use, etc., and achieve the effects of reducing costs, simplifying structure settings, and reducing mold improvement or manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

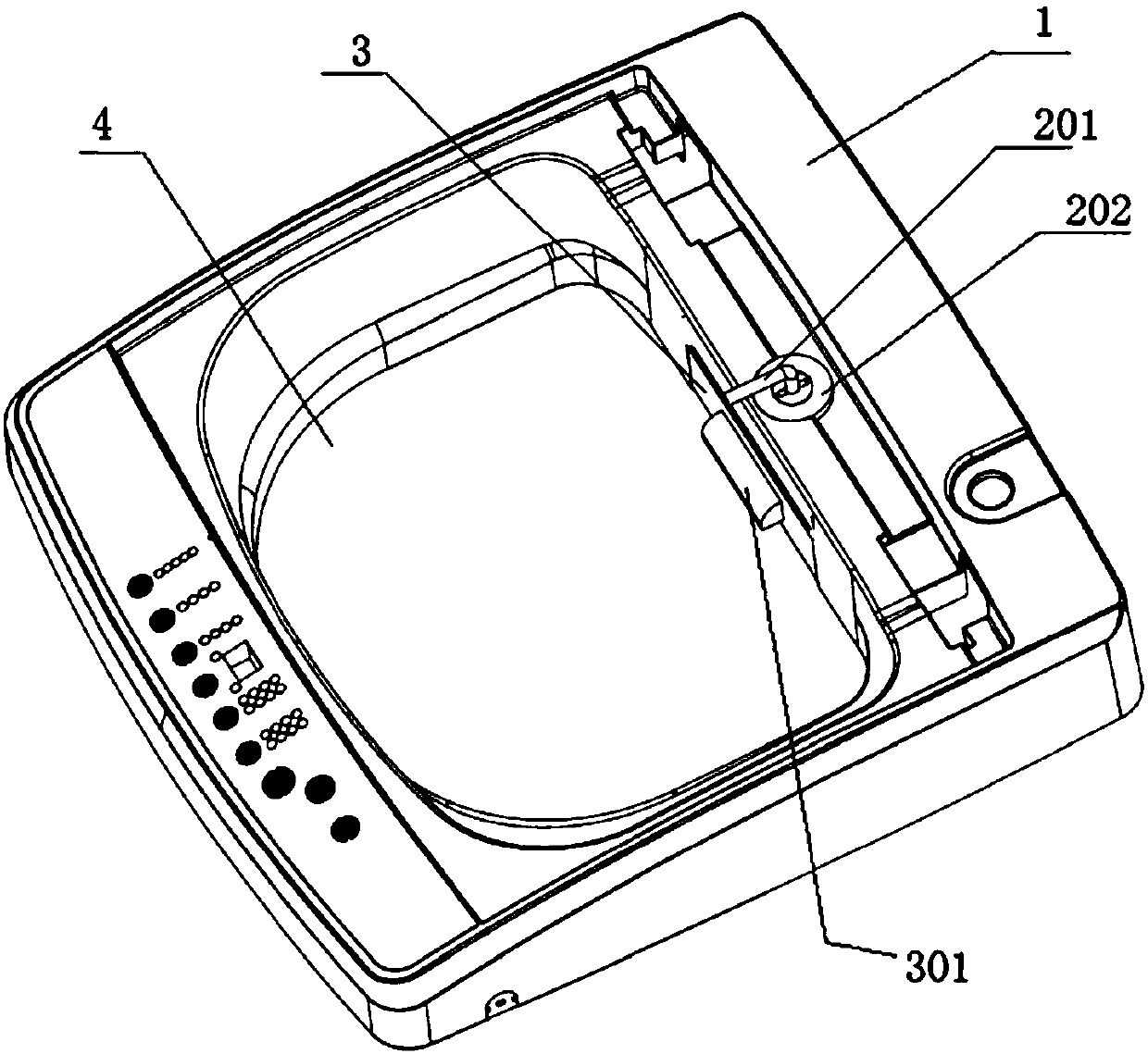

[0041] Such as Figure 1-8 As shown, the present embodiment relates to a detergent dispensing device, and the detergent dispensing device is used in a washing machine.

[0042] The detergent dispensing device includes: a box body 3 arranged above the inner tub of the washing machine for holding detergent; a dispensing structure 2, the lower part of the dispensing structure 2 is connected with the interior of the box body 3 and forms a dispensing channel, which can be The pressing and reciprocating elements control the opening and closing, and the upper part is provided with a liquid outlet pipe 201 that is connected to the delivery channel and injects detergent into the inner bucket.

[0043] refer to Figure 1-6 , as an embodiment of the present invention, the box body 3 is arranged on the lower part of the tray base 1 of the washing machine, and the liquid outlet pipe 201 of the delivery structure 2 is arranged on the upper surface of the tray base 1 .

[0044] The box bod...

Embodiment approach

[0054] As an embodiment of the present invention, the box body 3 is pullably arranged at the lower part of the tray base 1 of the washing machine, and the delivery structure 2 is detachably connected to the inside of the box body 3 .

[0055] The drawable setting of the box body 3 can facilitate the user to take it out and add detergent, and also makes full use of the structural features of the existing washing machine to simplify the setting of the washing machine.

[0056] The delivery structure 2 is detachably connected to the inside of the box body 3 , and when detergent needs to be added to the box body 3 , only the box body 3 needs to be taken out without affecting the delivery structure 2 .

[0057] The delivery structure 2 is integrally formed or detachably connected with the tray base 1 .

[0058] The delivery structure 2 is integrally formed with the disc base 1, so that the delivery structure 2 is fixedly connected to the disc base 1 to avoid accidental loss.

[00...

Embodiment 2

[0072] This embodiment is a further optimization of the technical solution of the first embodiment.

[0073] refer to Figure 7 with 8 , a cover 202 is provided below the liquid outlet pipe 201, the cover 202 is connected to the upper part of the buffer chamber 207 and can move up and down, the upper surface of the disc base 1 is provided with a cavity for accommodating the cover 202, the cavity An elastic reset structure for pushing out or pulling in the cover body 202 is provided inside.

[0074] When it is necessary to inject detergent, press the cover body 202, and the elastic reset structure will push the cover body 202 out of the concave cavity, and at this time, the detergent can be injected into the inner bucket by pressing the liquid outlet pipe 201. When the detergent is put in, press the cover body 202 again, the cover body 202 is pulled by the elastic reset structure and enters the concave cavity, and the cover body 202 and the upper surface of the tray base 1 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com