Interval-adjustable automatic micro-scribing glass cutting device

A glass cutting and driving device technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of low cutting efficiency and achieve the effect of improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

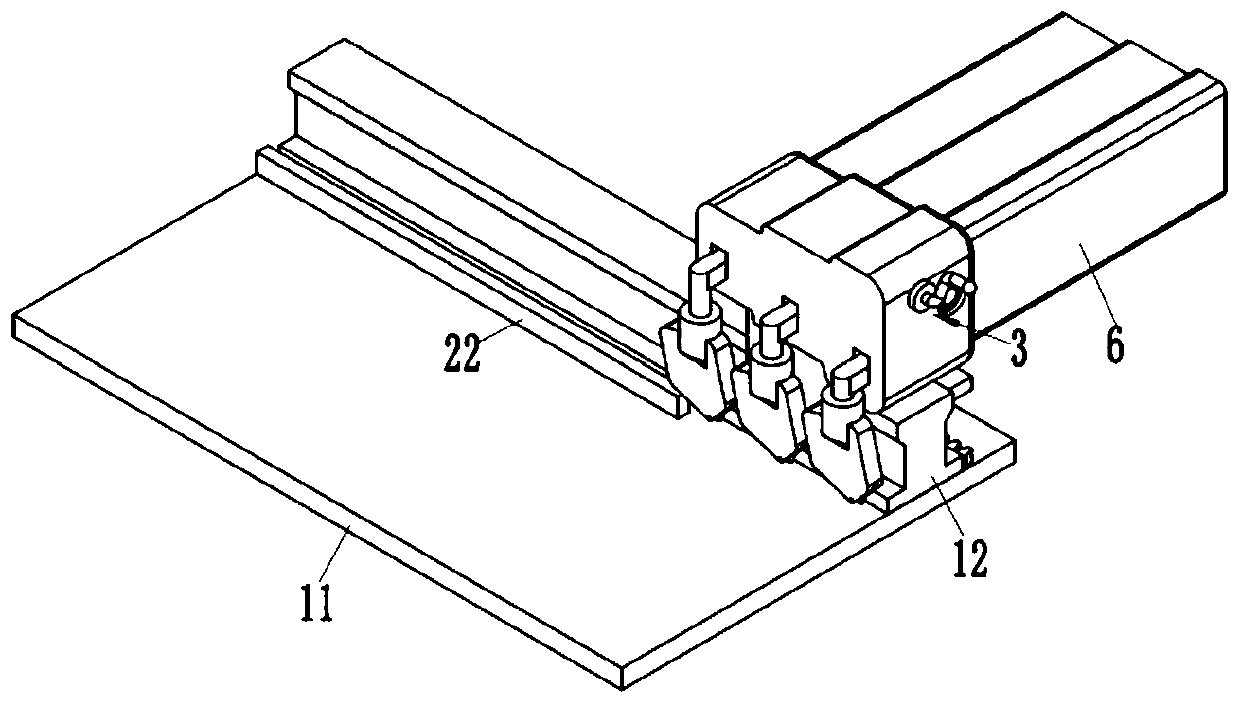

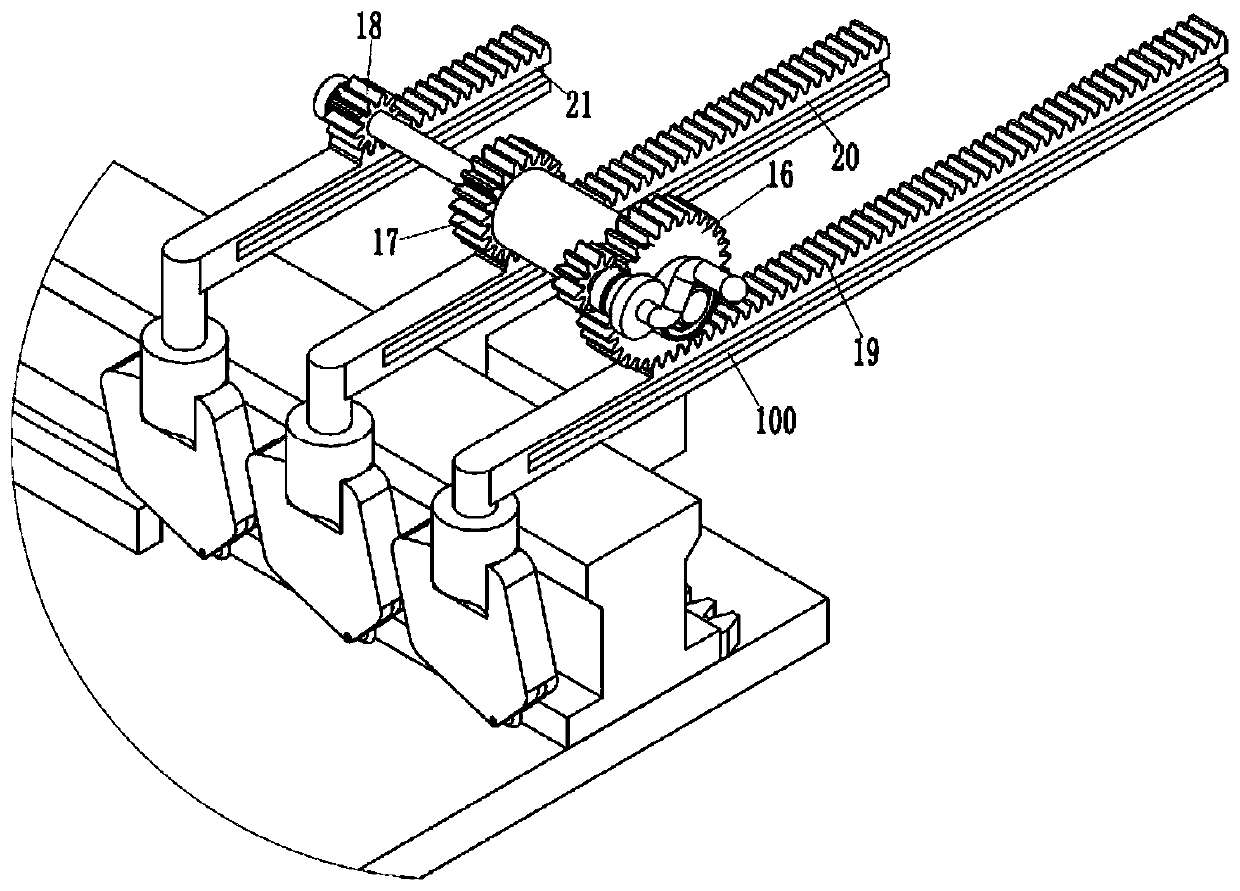

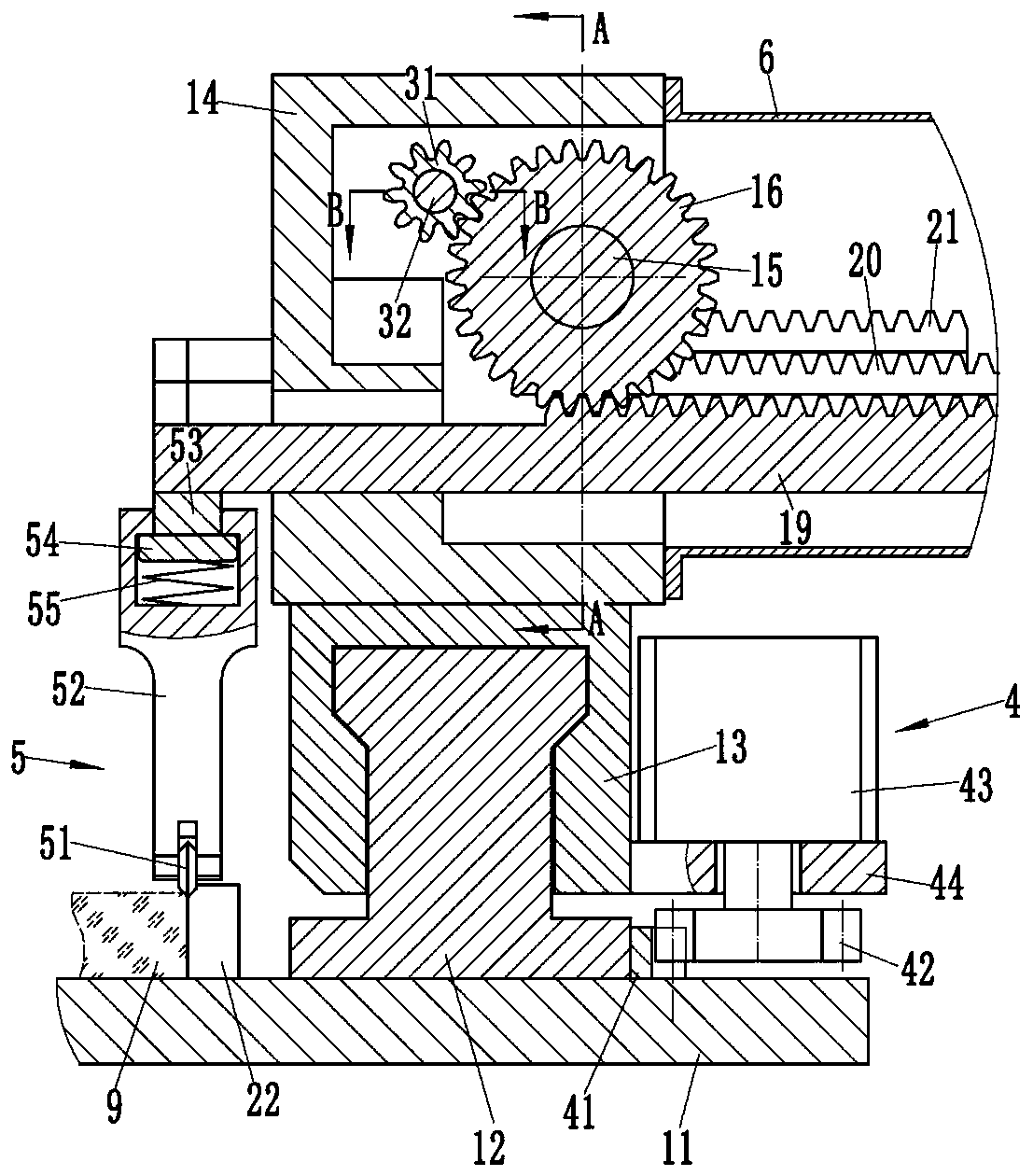

[0026] Examples, see e.g. Figure 1 to Figure 6 As shown, an automatic micro-scoring glass cutting device with adjustable spacing includes a flat plate 11, the right end of the flat plate 11 is fixed with a slide rail 12 arranged in the front and rear directions, and a slide block 13 is sleeved on the slide rail 12. The slide block 13 is provided with the driving device 4 that drives it to move back and forth, and the casing 14 of opening on the right side is fixed on the described slider 13, is hinged with the rotating shaft 15 between the front side wall and the rear side wall of the described cabinet 14, on the rotating shaft 15 from front To the rear, a large gear 16, a middle gear 17 and a pinion 18 are fixed in sequence, and the large gear 16 is meshed with a first rack 19 arranged in a left-right direction, the middle gear 17 is meshed with a second rack 20, and the pinion 18 is meshed with a The third rack 21, the second rack 20, and the third rack 21 are all arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com