Thermal coupling air separation unit energy-saving intelligent optimization system based on hybrid modeling

A hybrid modeling and intelligent optimization technology, which is applied in the fields of instruments, data processing applications, prediction, etc., can solve problems such as low accuracy, low online operation efficiency, and inability to effectively reflect the complex nonlinear physical characteristics of the air separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be described in detail below according to the accompanying drawings.

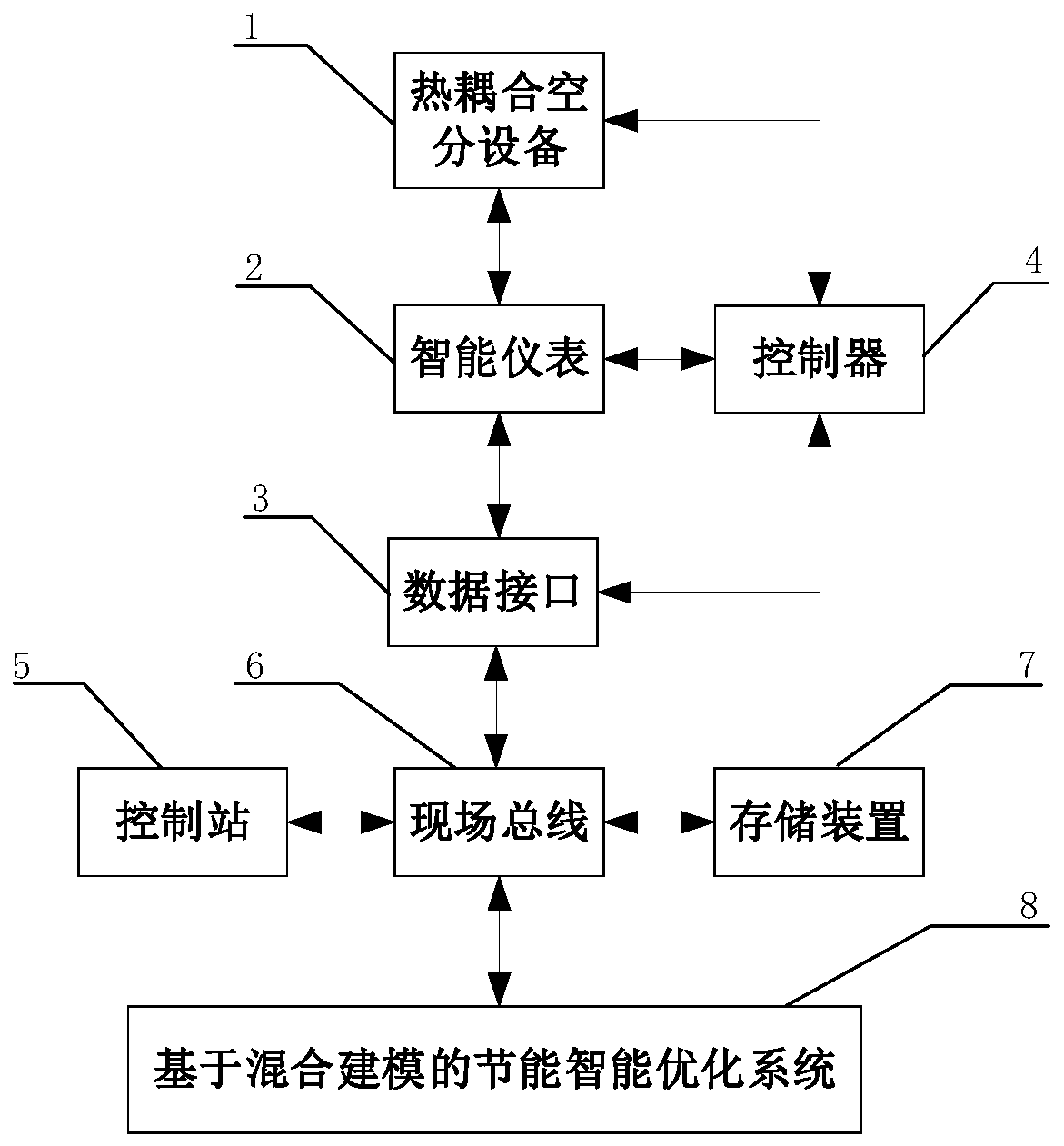

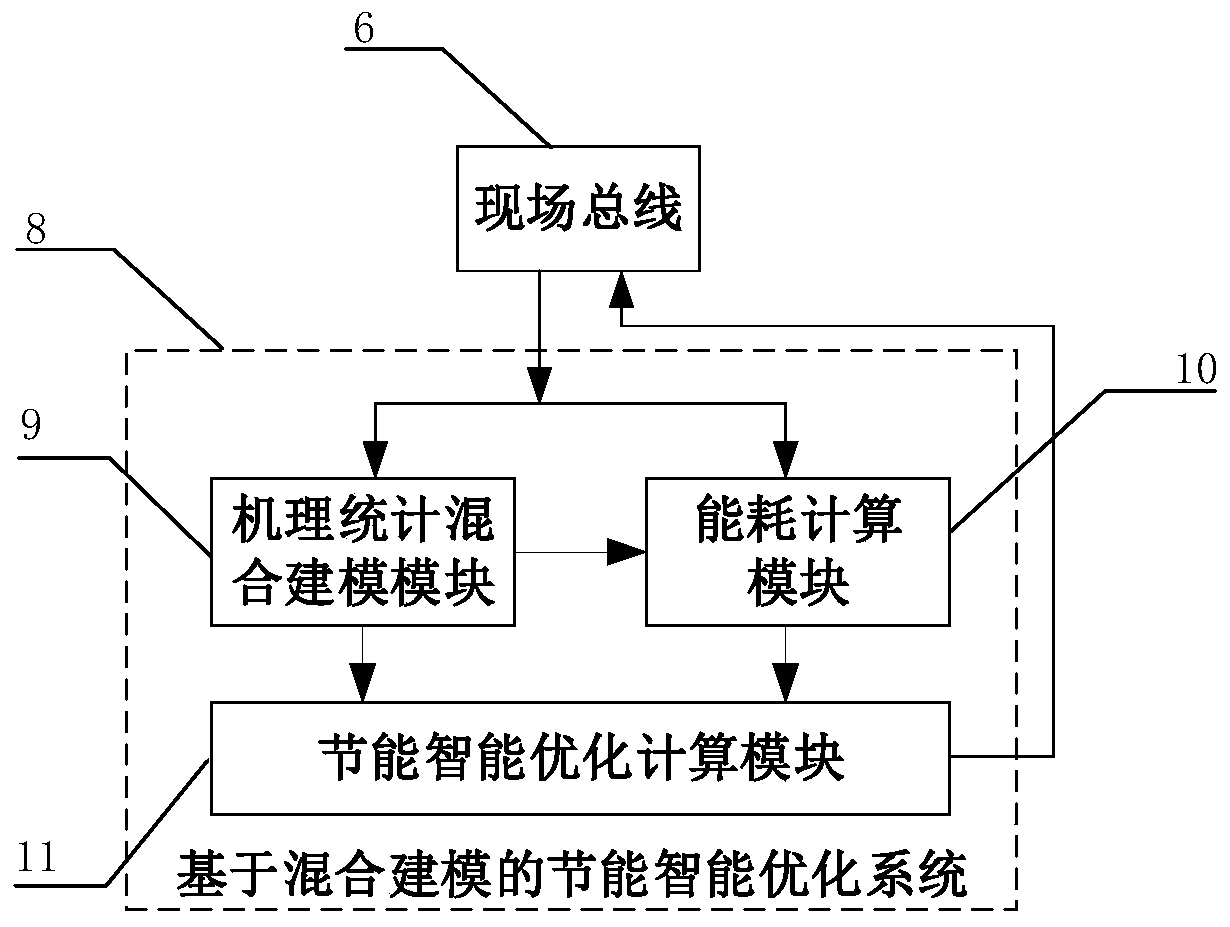

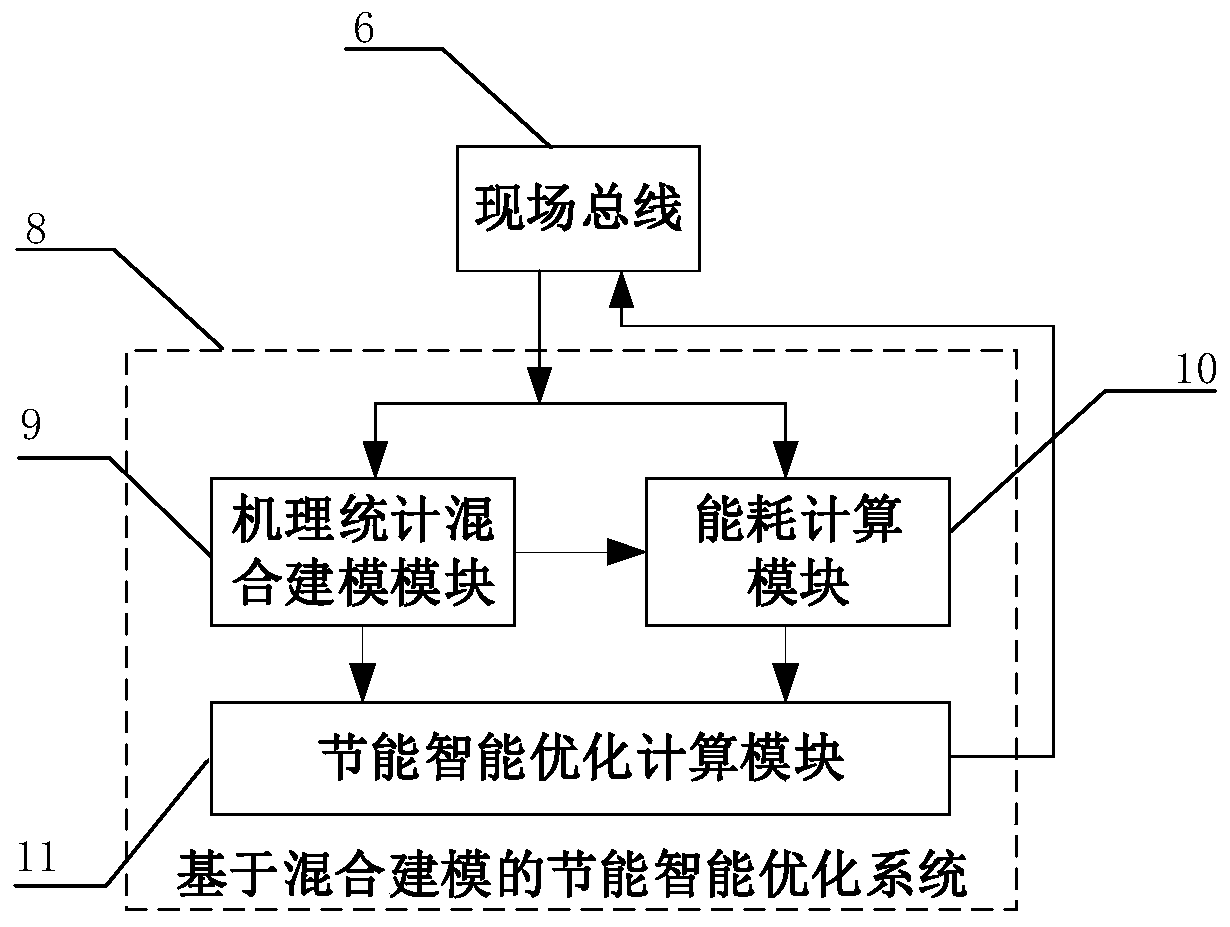

[0066] refer to figure 1 , the air separation production process includes air separation equipment 1, intelligent instrument 2, data interface 3, controller 4, control station 5, field bus 6, storage device 7 and energy-saving intelligent optimization system 8 based on hybrid modeling, in which the intelligent instrument 2 , the controller 4 is directly connected with the air separation plant 1, the control station 5, the storage device 7 and the energy-saving intelligent optimization system 8 based on hybrid modeling are connected with the smart instrument 2 and the controller 4 through the field bus 6 and the data interface 3 . The smart meter 2 measures relevant parameters through temperature detection elements, pressure detection elements, and flow detection elements, and is connected to the data interface 3 . The energy-saving intelligent optimization system 8 based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com