Industrial process abnormal condition prediction method based on operation parameter correlation analysis

A technology of correlation analysis and operating parameters, which is applied in forecasting, data processing applications, electrical digital data processing, etc., to achieve the effect of complete equipment abnormal information and predicting results in advance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

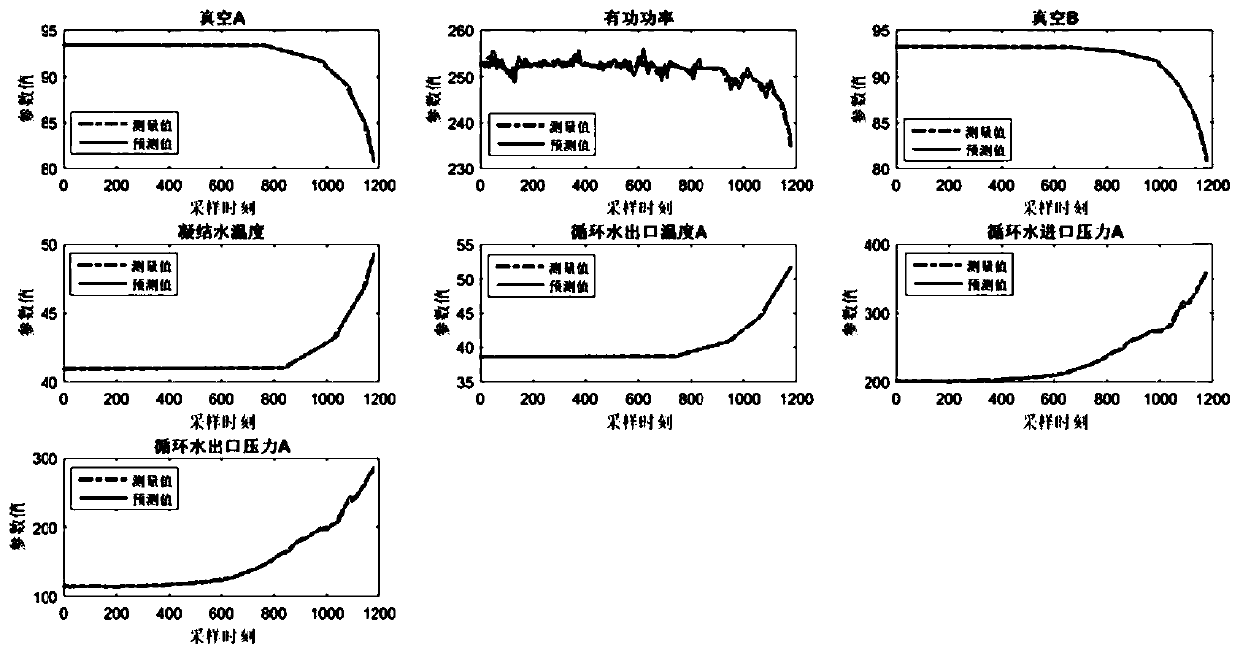

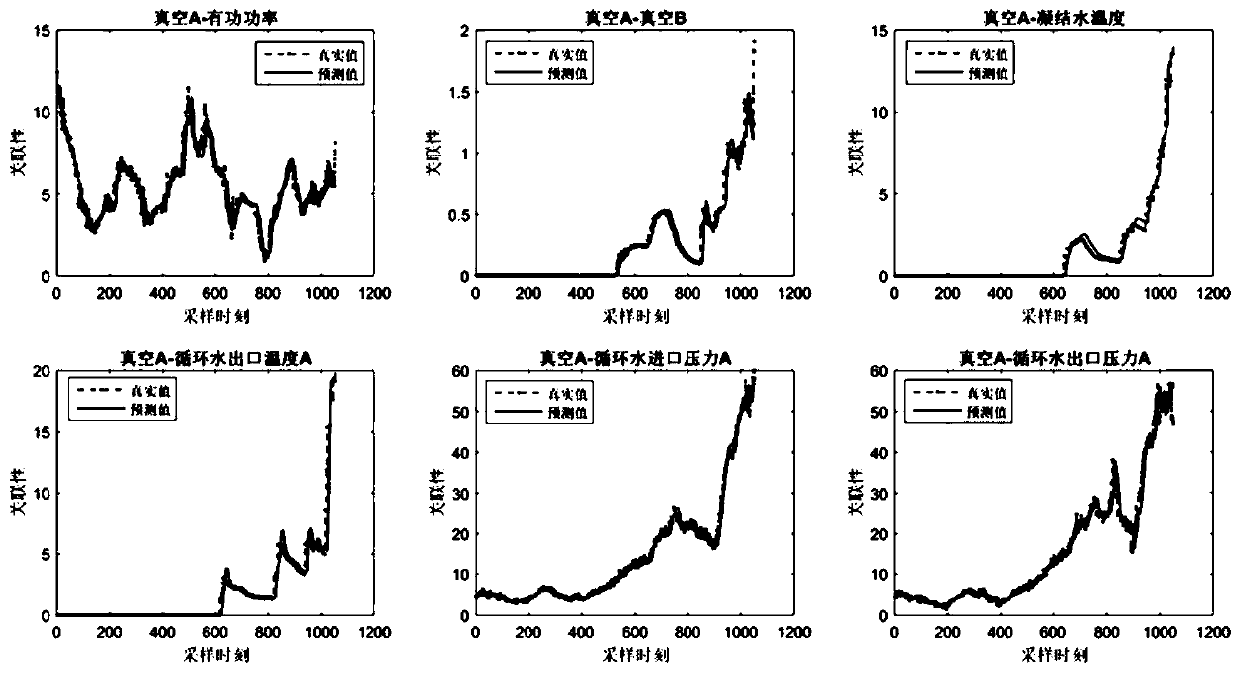

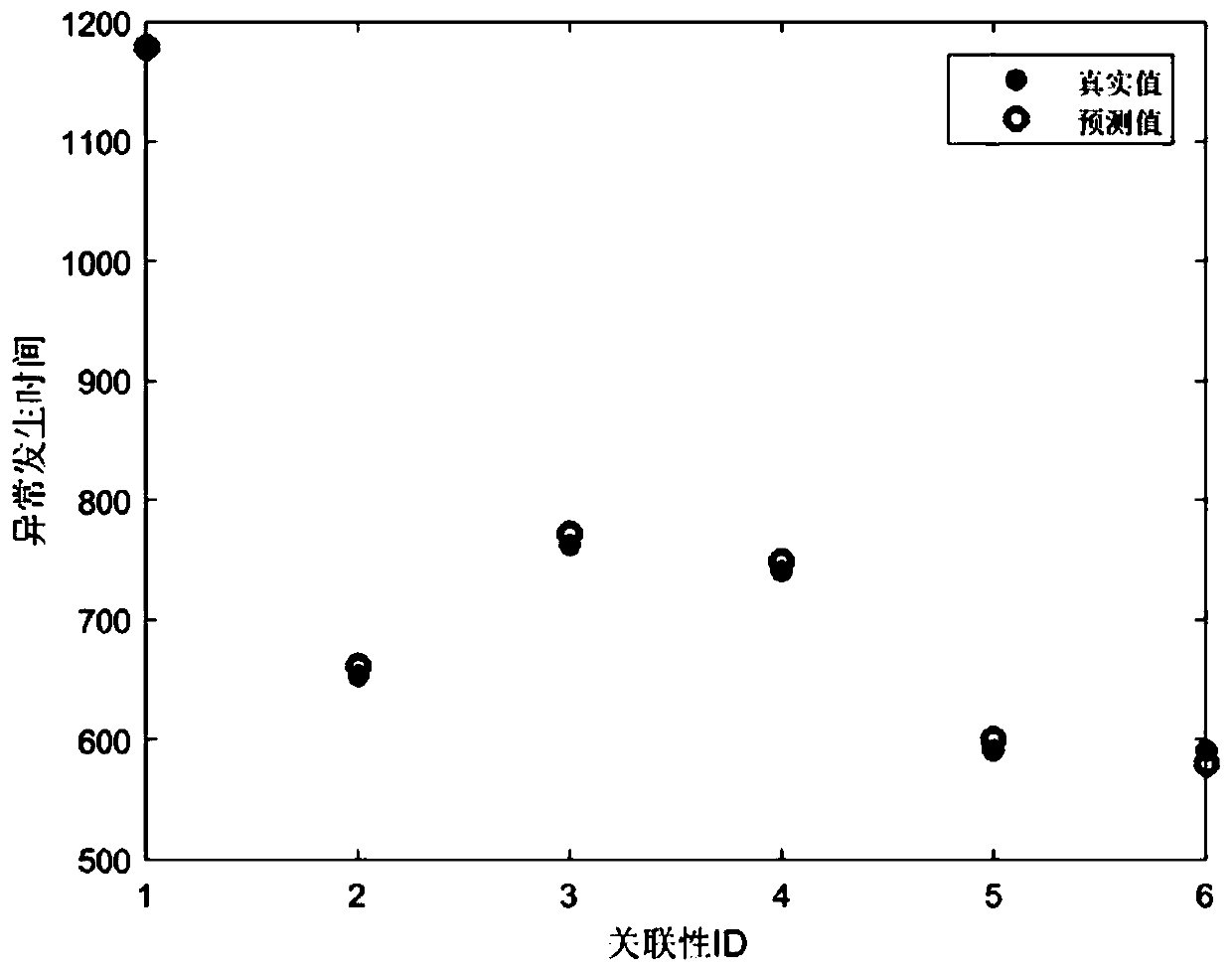

[0060] The specific implementation of the present invention will now be further described in conjunction with the accompanying drawings. Part of the principles have been described in detail above and will not be repeated here. The following example uses a real case based on the trip data of the low vacuum protection of the steam turbine to illustrate the specific operation steps and verify the effectiveness of the proposed method.

[0061] This milling machine data records the degradation of the operation of cutting metallic materials with milling cutters. The initial operating condition of the steam turbine is load 250MW, condenser vacuum 93kPa, with the condenser vacuum value as the indicator parameter, vacuum A starts to indicate abnormality from the 762nd sampling point, when the vacuum value drops to 81kPa, the steam turbine trips machine. The method for predicting abnormal working conditions of industrial processes includes the following steps:

[0062] Step 1: Use the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com