Workpiece stabilizing and fixing mechanism for machining grinding machine

A fixed mechanism and machining technology, applied in the direction of grinding workpiece supports, etc., can solve the problems of reducing the efficiency and accuracy of workpiece machining, workpiece machining errors, poor positioning effect, etc., to increase positioning effect, increase stability, increase The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

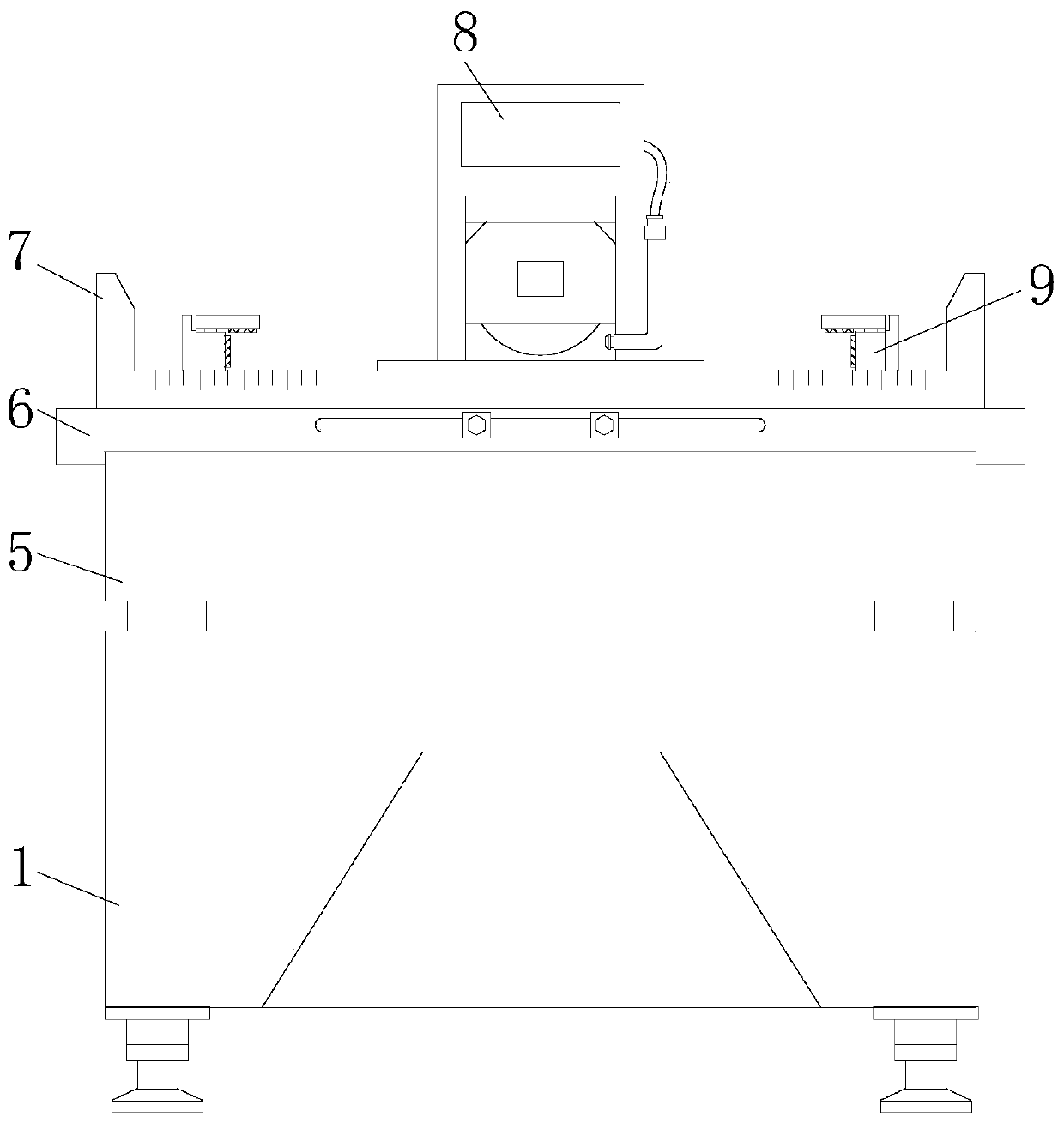

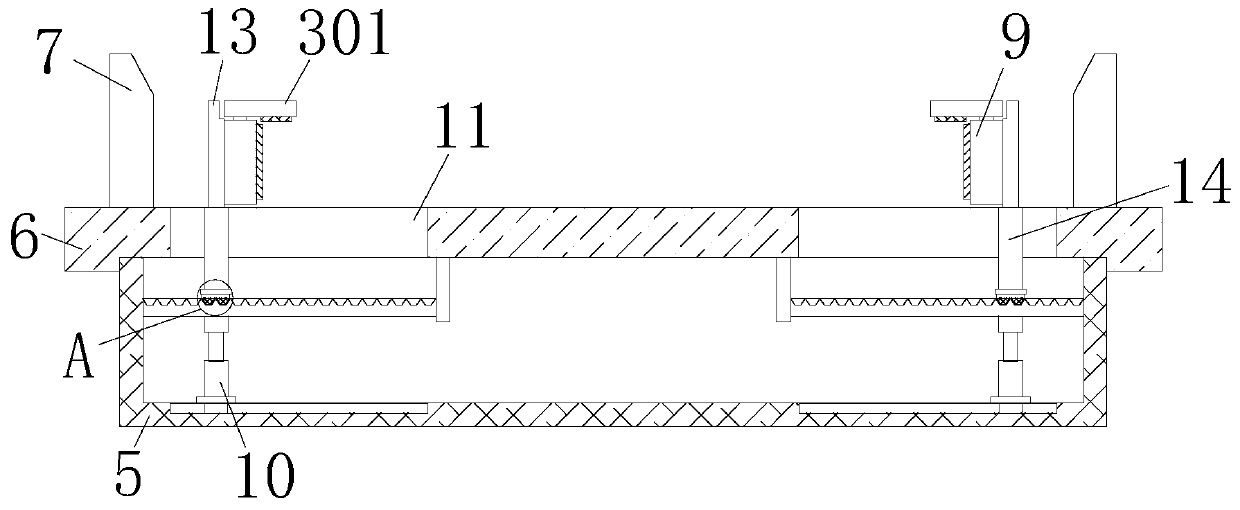

[0034] refer to Figure 1-9 , the stabilizing and fixing mechanism of workpieces for machining grinding machines of the present invention comprises a bottom box 1, the top of the bottom box 1 is fixedly connected with a fixed shell 5, the top of the fixed shell 5 is fixedly connected with a top plate 6, and the top of the top plate 6 is fixedly connected with a grinding wheel. Cutting equipment 8, both sides of top plate 6 top are all movably connected with movable plate 13, and the opposite side of two movable plates 13 is all fixedly connected with positioning shell 9, and the top of positioning shell 9 is movably connected with positioning mechanism 3, and positioning mechanism 3 The bottom of the top plate penetrates to the inner cavity of the positioning shell 9 and is fixedly connected with the inner wall of the positioning shell 9. The bottom of the movable plate 13 is fixedly connected with a slide plate 14, and both sides of the top plate 6 are provided with a first po...

Embodiment 2

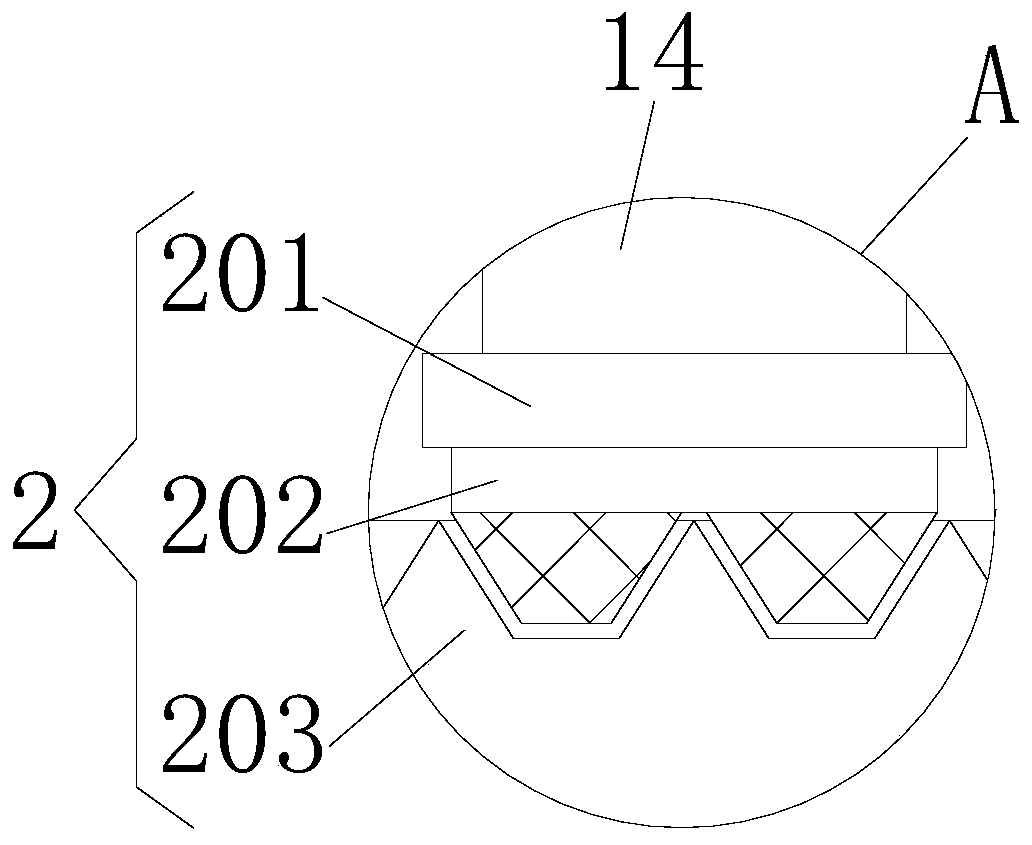

[0036] In a preferred embodiment, the limit mechanism 2 includes a limit plate 201, the rear side of the limit plate 201 is fixedly connected with the slide plate 14, the bottom of the limit plate 201 is fixedly connected with a block 202, and the two sides of the inner cavity of the fixed shell 5 Both sides are provided with clamping plates 203 used in conjunction with the clamping blocks 202 .

[0037] In a preferred embodiment, the positioning mechanism 3 includes a positioning plate 301, the bottom of the positioning plate 301 is fixedly connected with an engaging plate 302, the bottom of the engaging plate 302 penetrates into the inner cavity of the positioning shell 9 and is fixedly connected with a connecting block 303, the connecting block The bottom of 303 is fixedly connected with extension spring 304 , and the bottom of extension spring 304 is fixedly connected with the inner wall of positioning shell 9 .

[0038]In a preferred embodiment, the fixing mechanism 4 inc...

Embodiment 3

[0040] In a preferred embodiment, a positioning block is fixedly connected to the side of the clamping plate 203 away from the inner wall of the fixed shell 5 , and the top of the positioning block is fixedly connected to the inner wall of the fixed shell 5 . By arranging the limit mechanism 2, the effect of limiting the slide plate 14 is effectively realized, preventing the slide plate 14 from shaking left and right, thereby increasing the stability of the positioning shell 9 after adjustment, preventing the shaking of the positioning shell 9, thereby increasing The accuracy of workpiece processing is improved, and by setting the positioning block, the function of supporting and fixing the clamping plate 203 is effectively realized, thereby increasing the stability of the clamping plate 203. The surface of the connecting plate 302 is covered with a stabilizing sleeve, and the top of the stabilizing sleeve is fixedly connected with the inner wall of the positioning shell 9 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com