Dispersing device for coupled separation of oil and sand of lubricating oil

A dispersing device and lubricating oil technology, which is applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems that the dispersion effect cannot be guaranteed, and the lubricating oil cannot meet the standards, so as to achieve the effect of ensuring high efficiency and ensuring recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

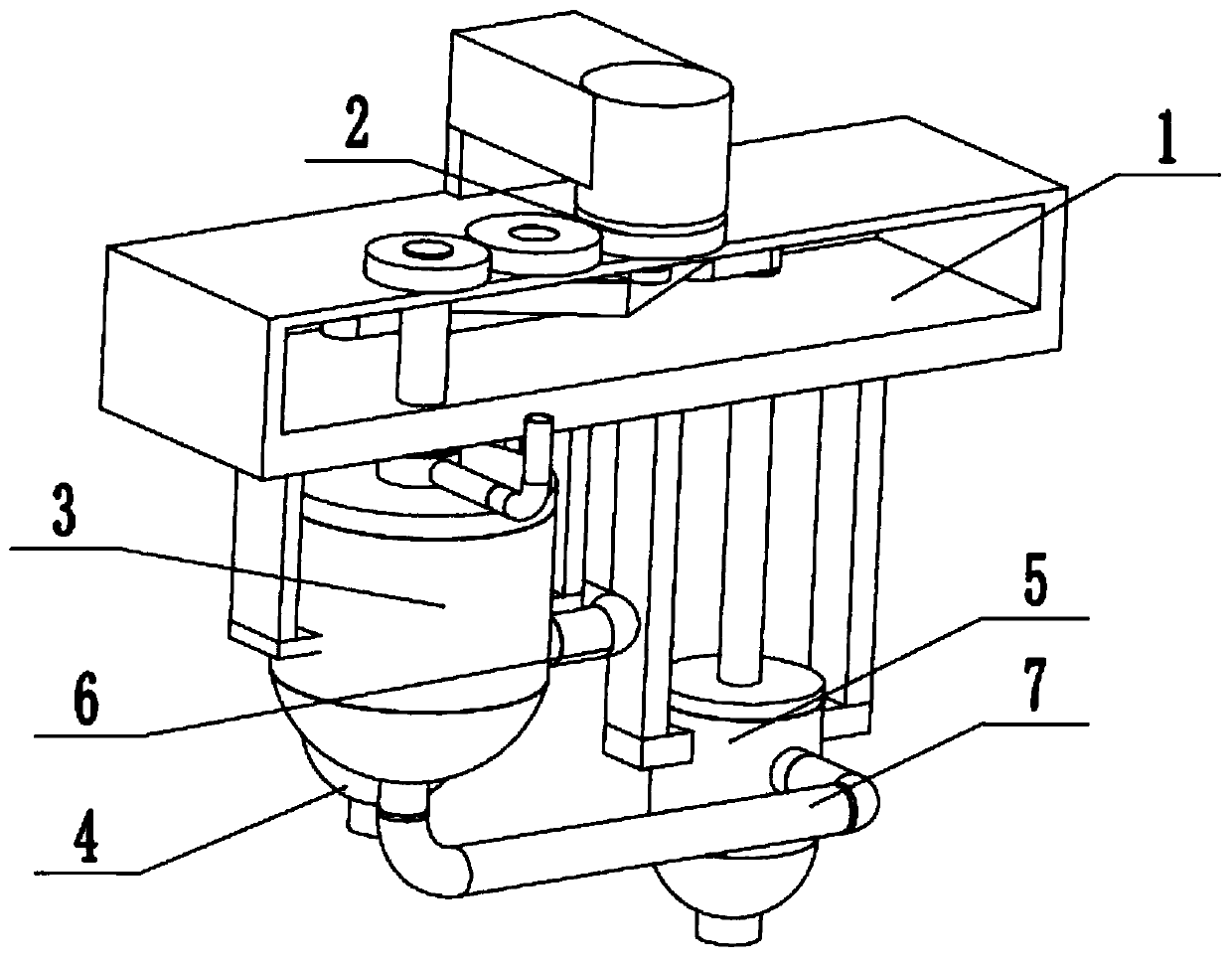

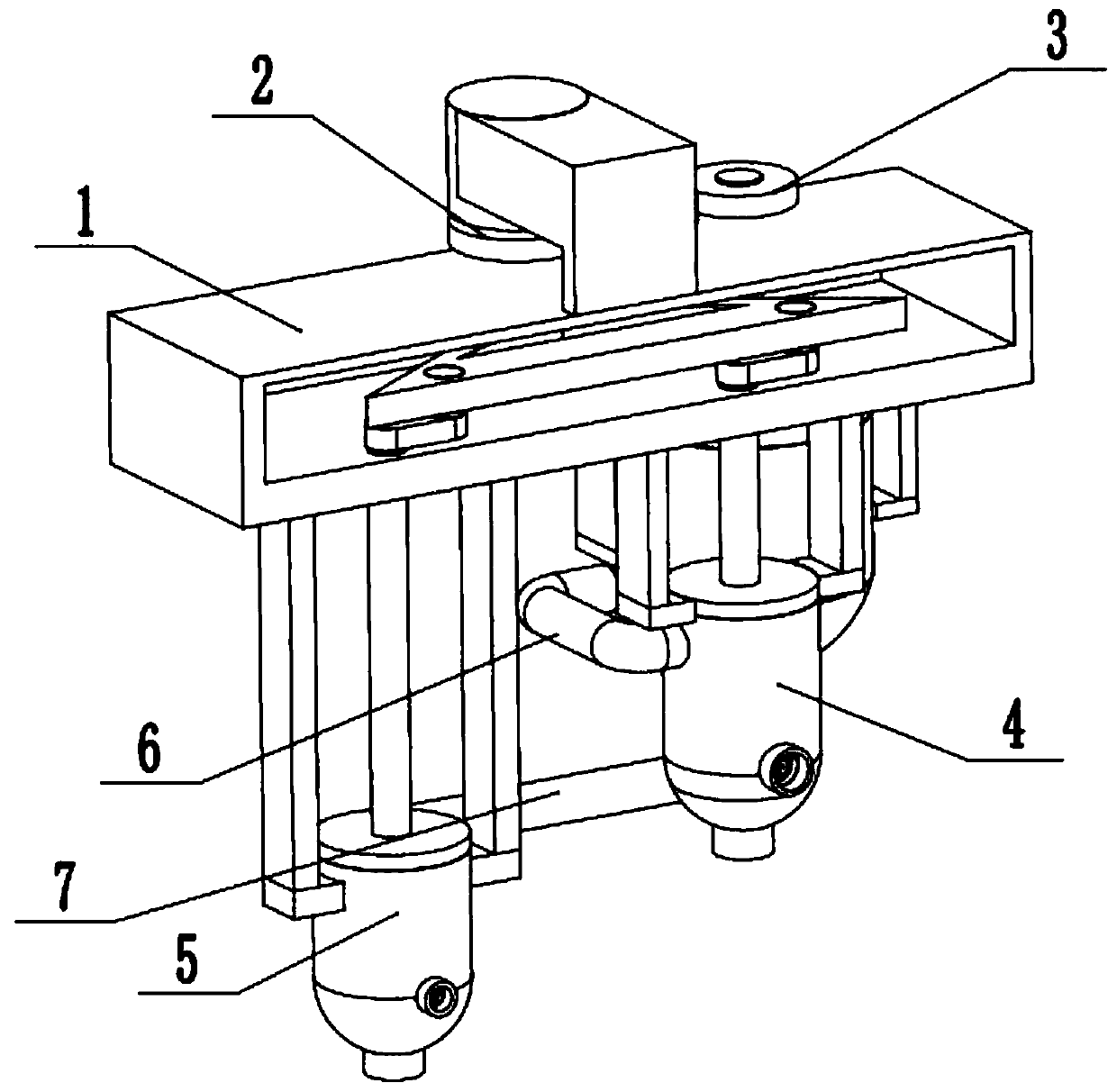

[0031] Such as Figure 1 to Figure 11 As shown, a dispersing device for coupling and separating lubricating oil, oil and sand, including a fixed base 1, a drive agitator 2, a centrifugal filter 3, a secondary oil filter agitator 4, a secondary sand filter agitator 5, and an oil separation connection Rod 6 and sand separation connecting pipe 7, the driving agitator 2 is fixedly connected to the upper end of the fixed base 1, the driving agitator 2 is rotatably connected in the fixed base 1, and the driving agitator 2 is engaged with the centrifugal filter 3 Transmission, the centrifugal filter 3 is connected to the secondary oil filter agitator 4 through the oil separation connecting rod 6, the centrifugal filter 3 is connected to the secondary sand filter agitator 5 through the sand separation connecting pipe 7, the centrifugal filter 3, and the secondary oil filter are stirred The upper ends of the device 4 and the secondary sand filter agitator 5 are fixedly connected to the...

specific Embodiment approach 2

[0033] Such as Figure 1 to Figure 11 As shown, this embodiment further describes the first embodiment, and the fixed base 1 is provided with a movable groove 1-1 that runs through from front to back. The fixed base 1 is used for fixing, and the movable slot 1-1 is used for space activities.

specific Embodiment approach 3

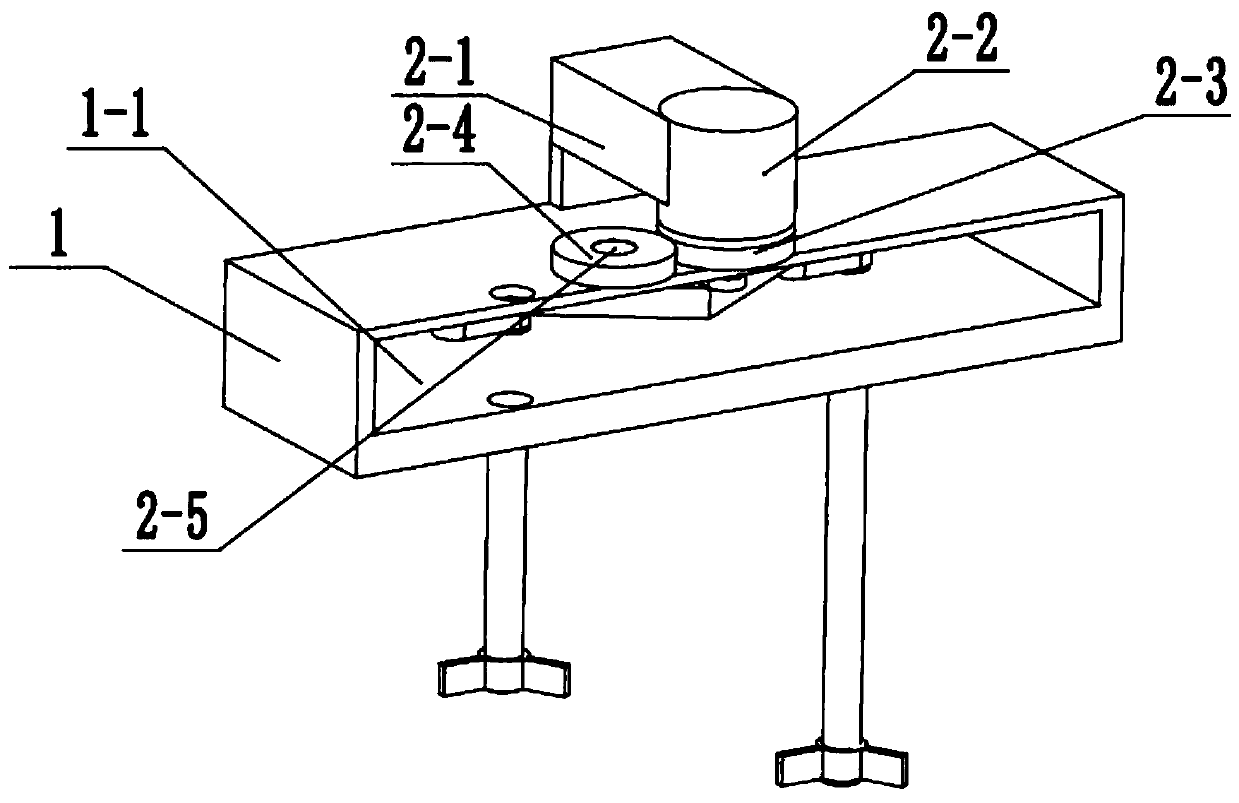

[0035] Such as Figure 1 to Figure 11 As shown, this embodiment will further describe the second embodiment. The drive agitator 2 includes a motor holder 2-1, a servo motor 2-2, a main drive gear 2-3, a transmission gear 2-4, and a transmission shaft 2-5, the main drive rod 2-6, the main hinge shaft 2-7, the triangle drive rod 2-8, the left hinge shaft 2-9 and the right hinge shaft 2-10, the motor holder 2-1 is fixedly connected to the fixed base On the seat 1, the servo motor 2-2 is fixedly connected to the motor fixing seat 2-1, the output shaft of the servo motor 2-2 is connected to the fixed base 1 in rotation, and the main drive gear 2-3 is fixedly connected to the servo motor 2- On the output shaft of 2, the left end of the main driving gear 2-3 meshes with the transmission gear 2-4, the transmission gear 2-4 is connected to the transmission shaft 2-5 in rotation, and the transmission shaft 2-5 is fixedly connected to the fixed base 1 The upper end of the main drive rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com