Straight strip folding device for sanitary towels and panty liners and folding method of straight strip folding device

A folding device and sanitary napkin technology, applied in absorbent pads, medical science, clothing, etc., can solve the problems of product folding stability, product shape effect cannot be guaranteed, device structure is complicated, and production efficiency is affected, and the product appearance is beautiful. The effect of generosity, high folding stability and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

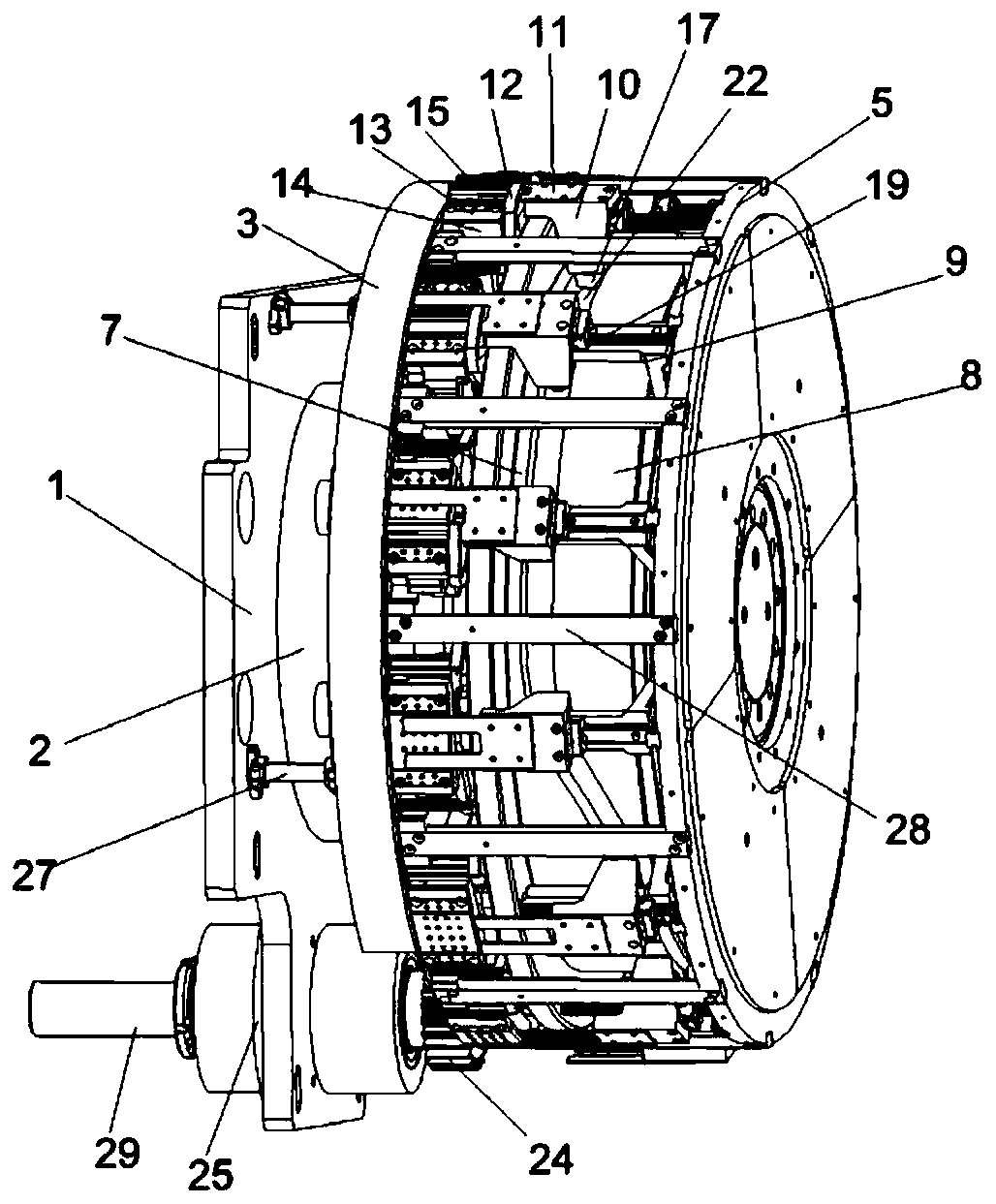

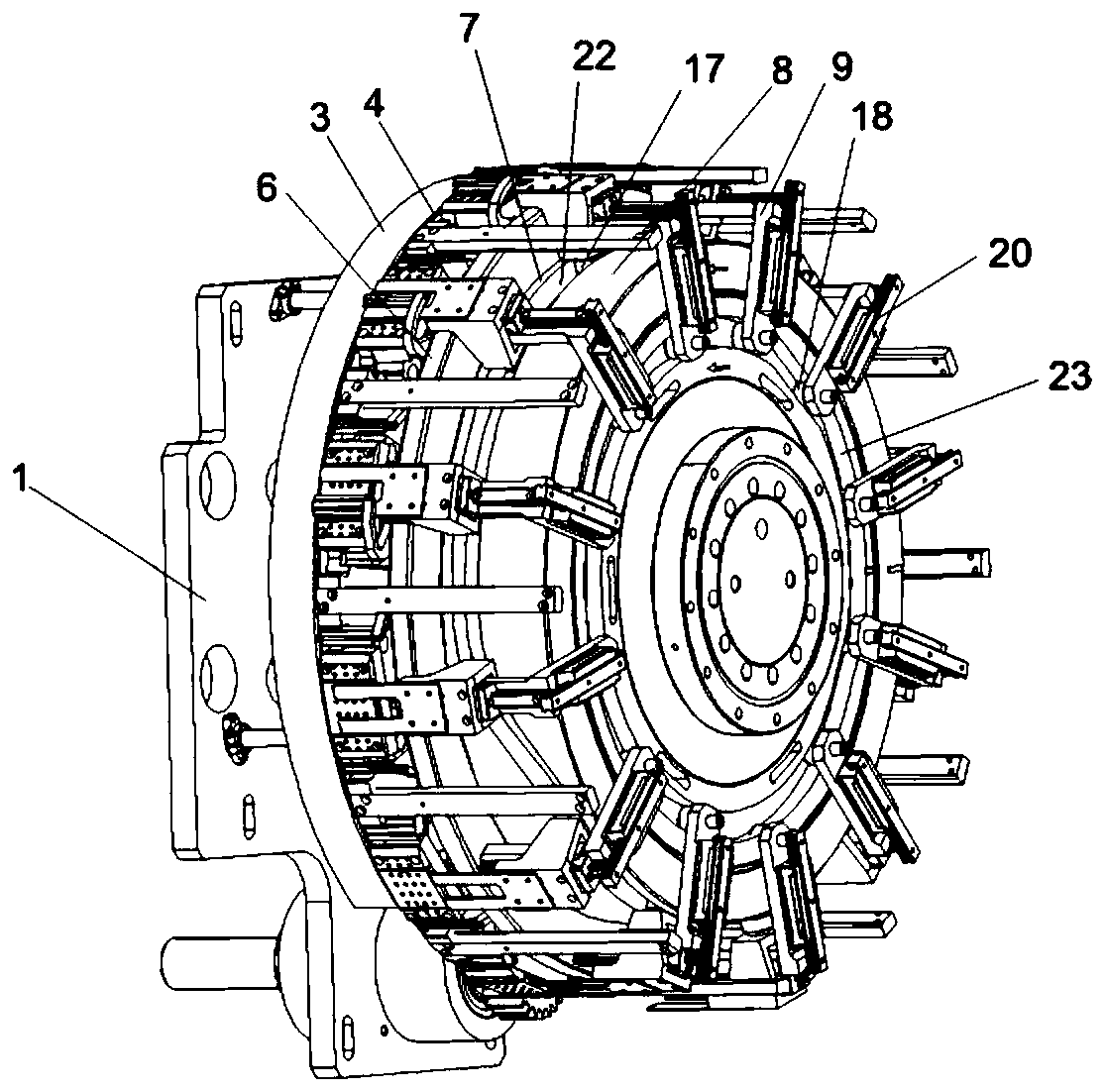

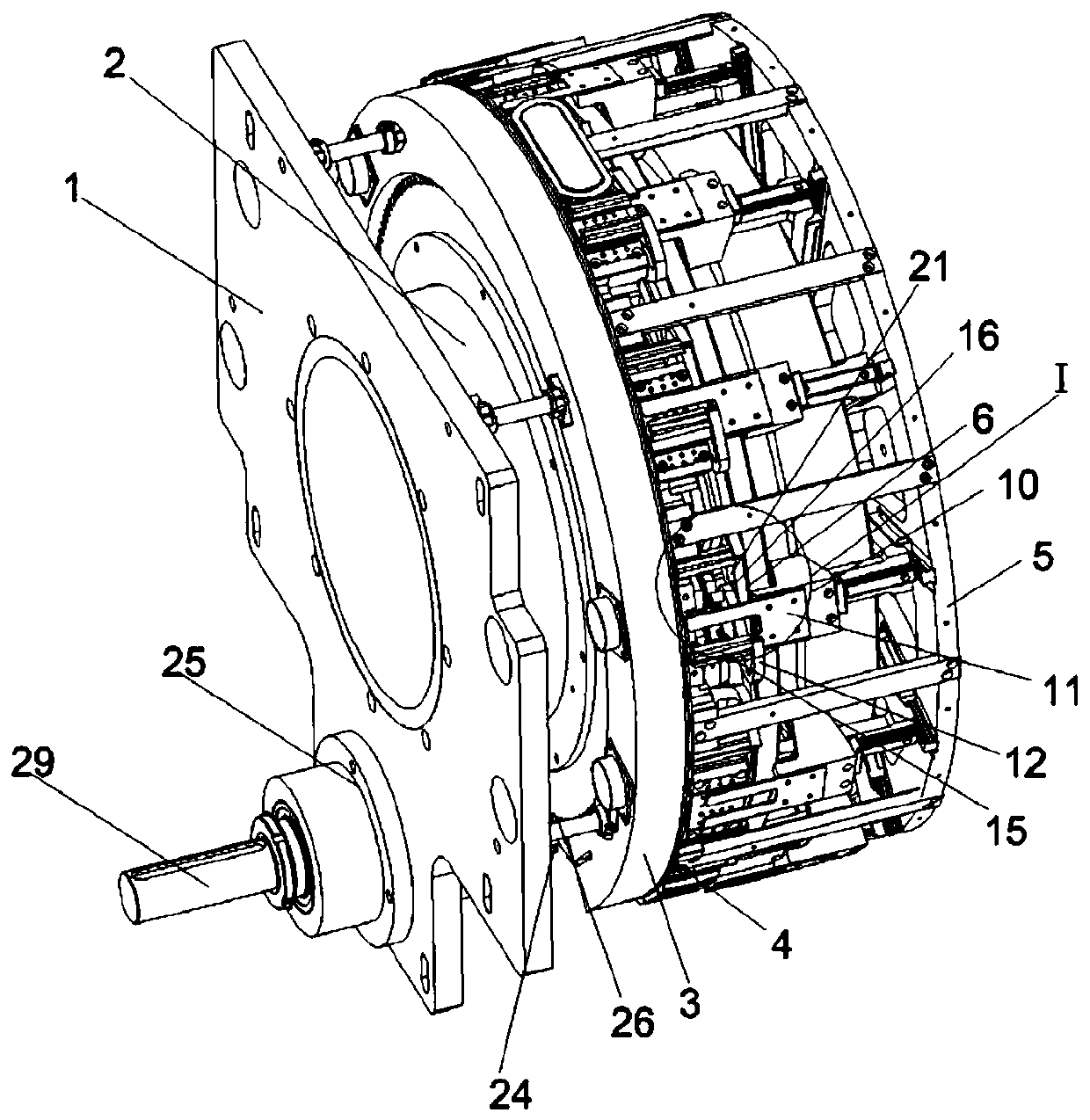

[0035] Such as Figure 1-4As shown, a straight folding device for sanitary napkins and pads includes a mounting plate 1, a main support shaft 2 installed on the mounting plate 1, an air distribution chamber 3, an inner rotating disk 4, an outer rotating disk 5, and driving the inner rotating disk 4 and The drive motor and transmission structure that the outer turntable 5 rotates. The outer turntable 5 and the inner turntable 4 rotate synchronously. A number of air boxes 13 are installed on the inner turntable 4. Each air box 13 is equipped with a pair of rocker arms 12. The inner turntable 4 and the outer turntable 5 are in sequence from the transmission side to the operation side. Rocker arm end face cam 6, center cam 7 and lift cam 8 are installed, one end of rocker arm 12 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com